Precision CNC Machining

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck: Advanced Composite Material Manufacturing for High-Performance Applications

Norck delivers expert composite manufacturing services for prototypes and production across aerospace, automotive, sporting goods, industrial, and other demanding sectors. Our skilled engineers, advanced facilities, and robust quality control ensure exceptional strength-to-weight ratios, precision tolerances, and complex geometries.

Capabilities for Composite Excellence:

Engineering Support for Composites:

Why Norck for Composite Manufacturing?

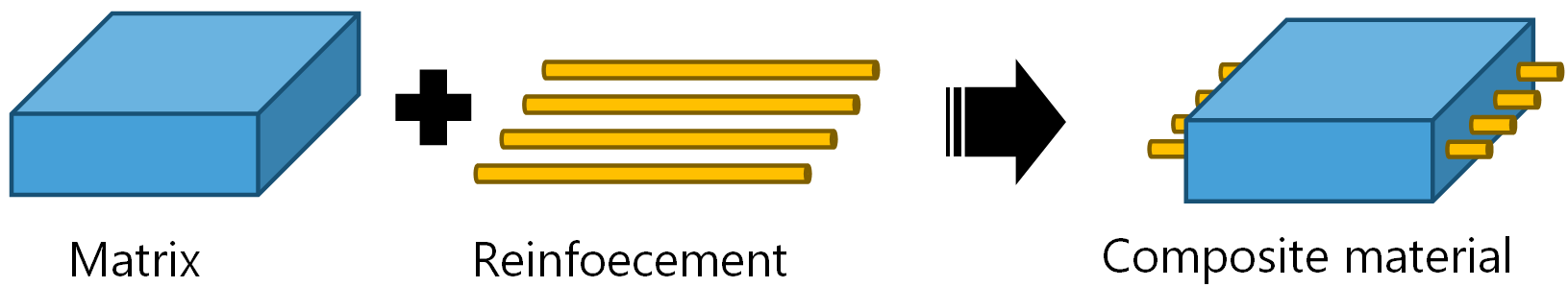

A composite material combines two or more materials with different physical properties to improve its properties.

Fiberglass is a widely known composite material that combines plastic and glass fibers. Fiberglass properties are a combination of plastic and glass. It is rigid, light, and durable. One of its uses is making roofing laminate, storage tanks, surfboards, and many other applications.

Another example is carbon fibers, combined with other materials, such as resin, to form a well-known material called carbon fiber (carbon fiber reinforced polymer). Carbon fiber is significantly more rigid than steel and much lighter. It is widely used, and some of its uses are aircraft bodies, sport cars bodies and seats, drone bodies, prostheses, bicycles, hockey, and baseball bats.

Composite manufacturing designates a set of fabrication methods used to manufacture a part. It is used in the following sectors:

- Medical: Surgical tools, implants, and orthopedics.

- Industrial: Jigs, fixtures, and enclosures.

- Aerospace & Automotive: Bodies of aircraft and cars, electrical cables

- Robotics: Robots' bodies, grippers

- Consumer products: Cooking utensils, swimming pools panels, shower stalls

Composite manufacturing offers many benefits, including:

• Highly customizable: Due to the combination of the materials, their properties are combined to result in better properties.

• Complex shapes: Depending on the mold, the shape of the workpiece can be complex

• Surface finish: Composite material parts have a smooth surface finish due to gel (applied in the process)

Composite materials are made through different manufacturing processes. Choosing the proper method depends on the functionality and aspect of the final product.

Generally, the composite comprises two materials, the matrix, and the reinforcement. Matrix materials, such as polymers, bind the reinforcement material, such as carbon fiber.

Mainly there are three types of composite materials

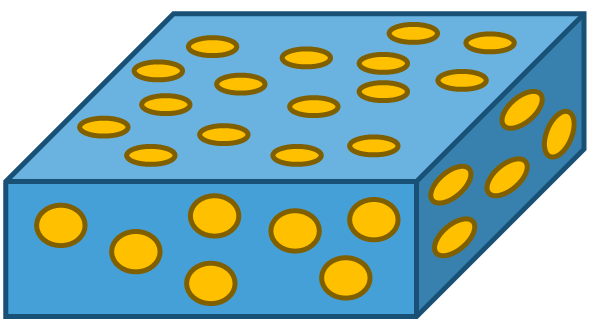

1. Article-reinforced: A particle-reinforced composite uses particles of reinforcement material in a matrix material. It is used for wear-resistant components such as road surfaces.

2. Natural composite: A composite material, such as bones and wood, can be found in nature.

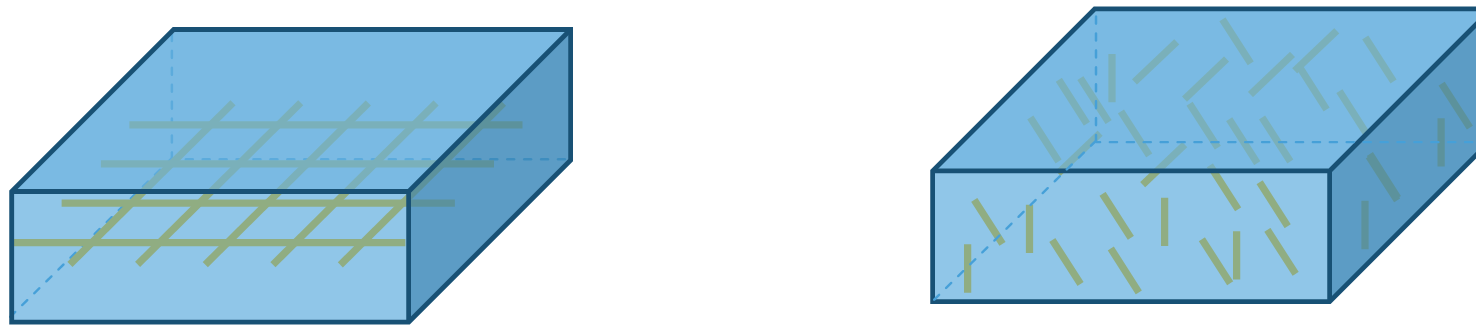

3. Fiber-Reinforced:In this type of composite, the reinforcement material consists of continuous or chopped fiber. It is used for

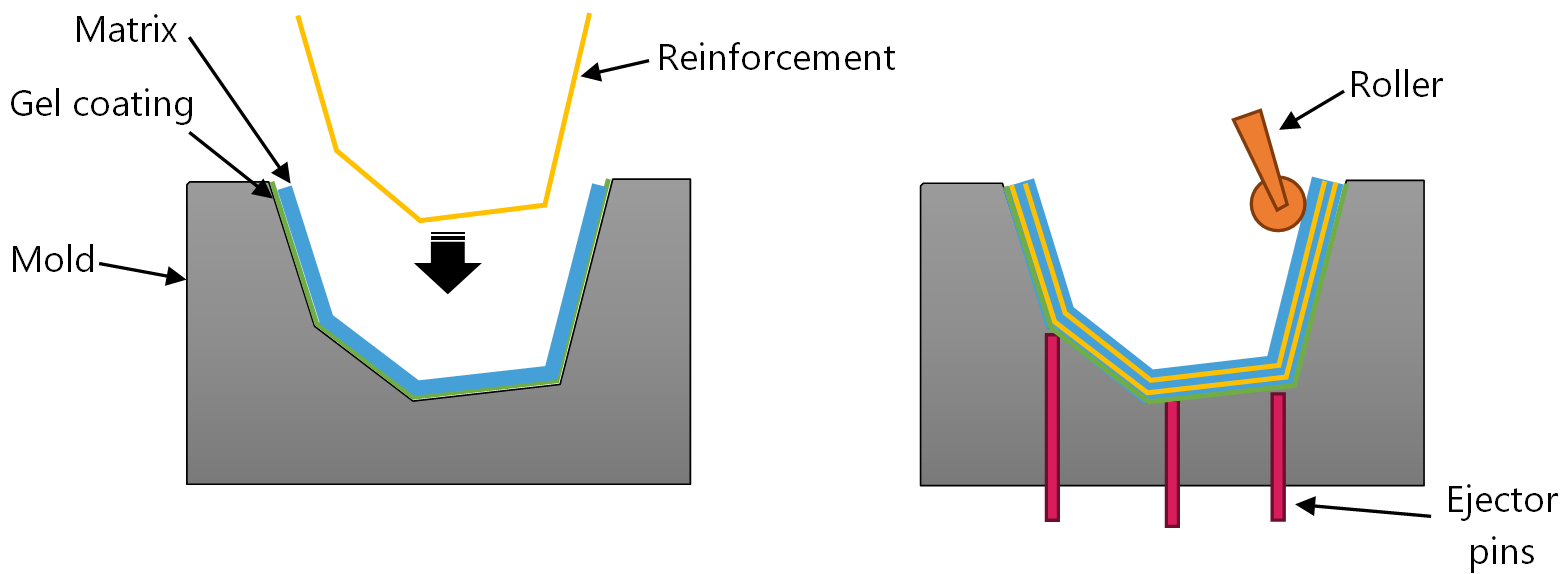

1. Hand lay-up: Unlike injection molding and die casting techniques, the used mold for this process consists only of one-half in which the final product shape is carved.

Firstly, the mold is cleaned, and a thin gel coating layer is applied. The gel coating provides a surface finish (color, smoothness, texture) and prevents the reinforcement and matrix from getting in contact with water or chemical. Upon the gel coating, a layer of matrix material is applied to the mold, this first layer will be the visible part, and it will have an excellent surface finish, for example, the external surface of a boat.

Then the reinforcement material is added, and a roller, a second layer of the matrix material, is applied to bind the reinforcement to the matrix. This process is repeated until the molded part reaches the desired thickness. Then the resin is cured to solidify the part. The last thing is ejected, whether manually or using ejector pins.

The limitation of this process is that the internal surface of the molded part doesn't have a good finish and shouldn't be used as a functional surface. Also, the production rate is low.

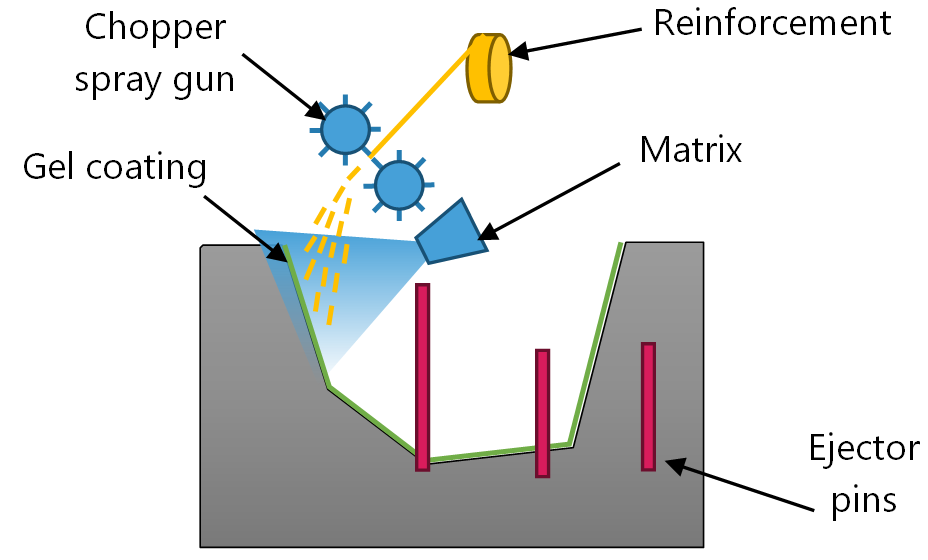

2. Spray lay up: Similar to the hand lay-up process, the spray lay-up process uses an open mold, but instead of manually laying the matrix and reinforcement, it is made using a sprayer that mixes both materials. The sprayer chops the reinforcement fiber into 1" to 2" chopped fiber.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

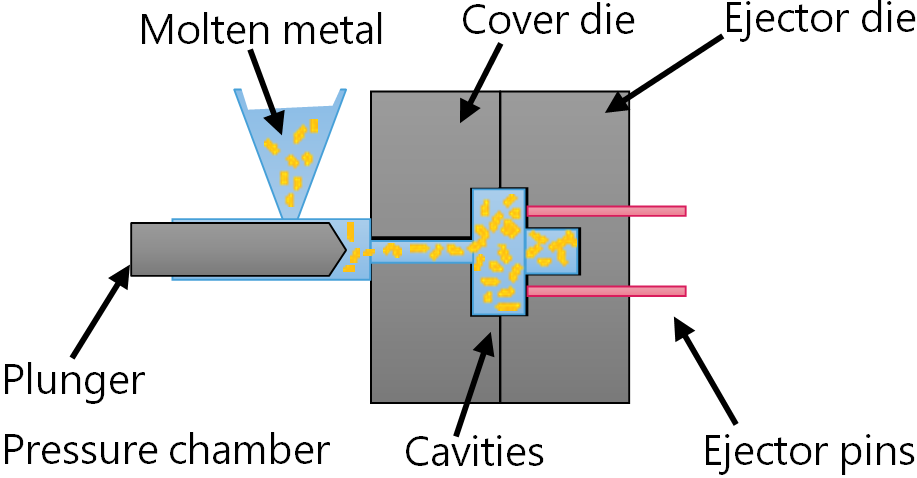

3. Injection molding: Injection molding uses a thermoplastic material with fiberglass. This process is made through four steps:

• Plastification: The plastic granules are transferred from the hopper to the mold using a rotating screw and molted using heaters.

• Injection: The screw will advance to increase pressure in the injection chamber to inject the molted plastic into the mold. The two cavities are maintained close until the plastic solidifies.

• Cooling: After injection, the molted plastic will be cooled down to become solid using a cooling circuit. The screw will hold its position to hold the pressure inside the mold.

• Ejection: After the molted plastic solidifies using a cooling circuit, the Die is opened, and the part is ejected via ejector pins. The screws will retreat to prepare for the next injection.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.