Precision Component Manufacturing with CNC Machining

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Norck: Achieve Complex Tube Forms with Precision Tube Bending

Norck delivers expert tube bending services, empowering manufacturers across aerospace, automotive, architectural, industrial, and other sectors to create complex tubular shapes with exceptional accuracy and repeatability.

Capabilities for Tube Bending Success:

Norck's Engineering Edge: It's About Solving Your Tubing Challenges

Why Choose Norck for Tube Bending?

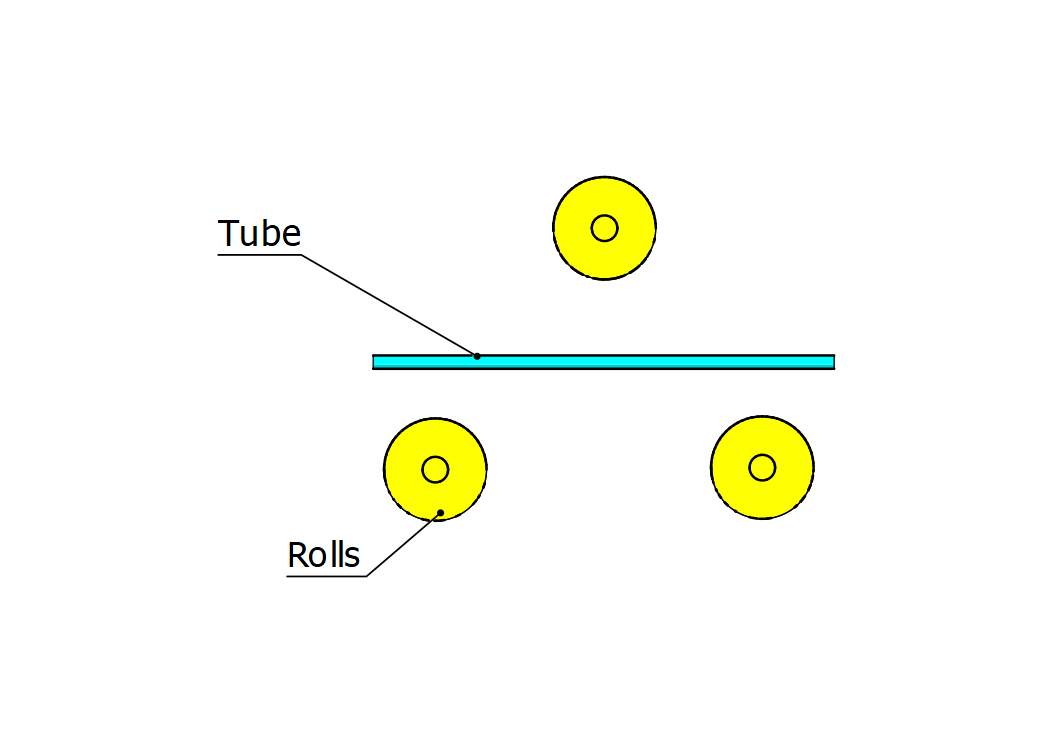

Tube bending is a set of techniques to bend straight tubes into different shapes. Bent tubes are used in structures, stair railings, and automotive parts. The process can be performed by using cold or hot methods. Generally, the round stock is used, but rectangular tubes and pipes can also be bent.

A post process can be mandatory to remove burrs. It can also be used with laser tube cutting to add holes and shapes or to cut the edges

Tube bending offers more advantages over traditional cutting, bending, and welding processes:

• Cost-effective: It helps minimize production costs since there are fewer parts and operations. Tube bending reshapes the tube without using welding or adding extra joints.

• Clean finish: Since there are no extra components or messy weldings, the tube finish will be smooth. It is most helpful in areas where the tube is apparent to the users, such as the stairs.

• No leakage: Tube bending eliminates the risk of leaking joints or weldments.

• Low-cost tooling: This process does not require a high tooling price compared to laser tube bending.

At Norck, we offer several tube bending techniques such as :

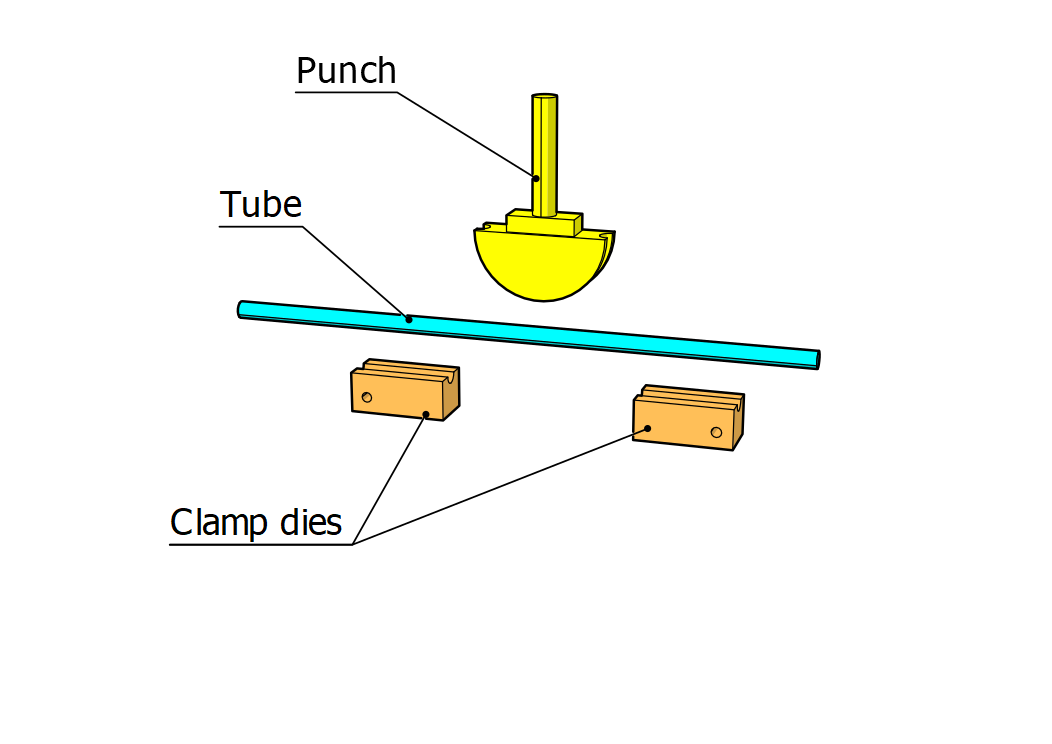

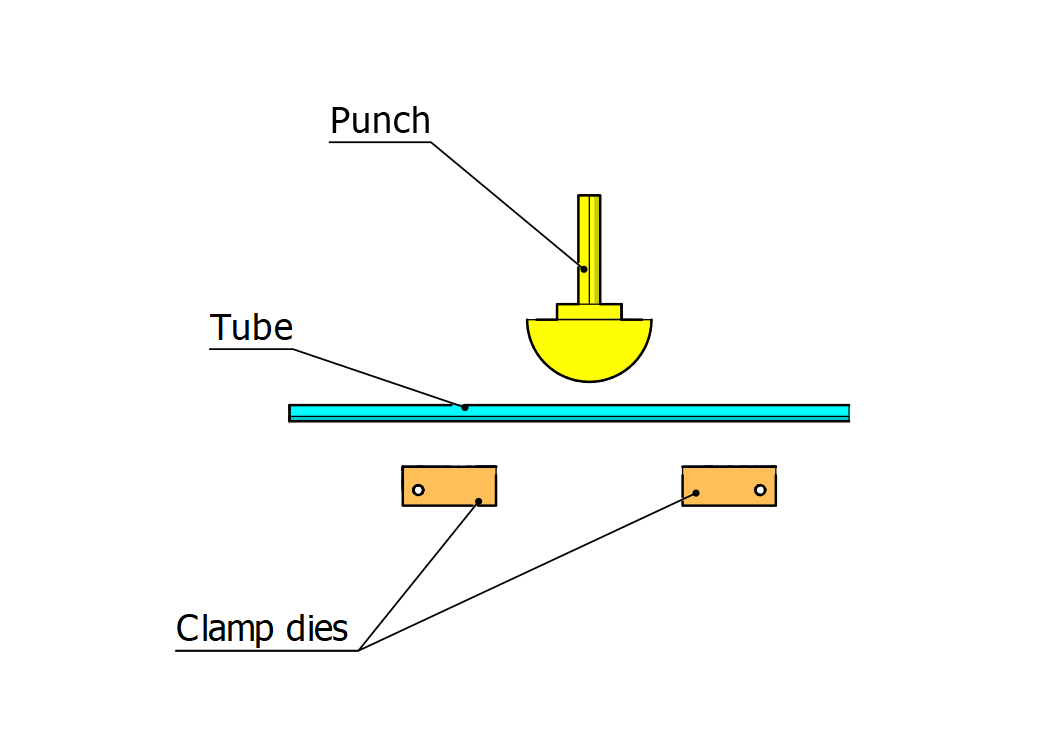

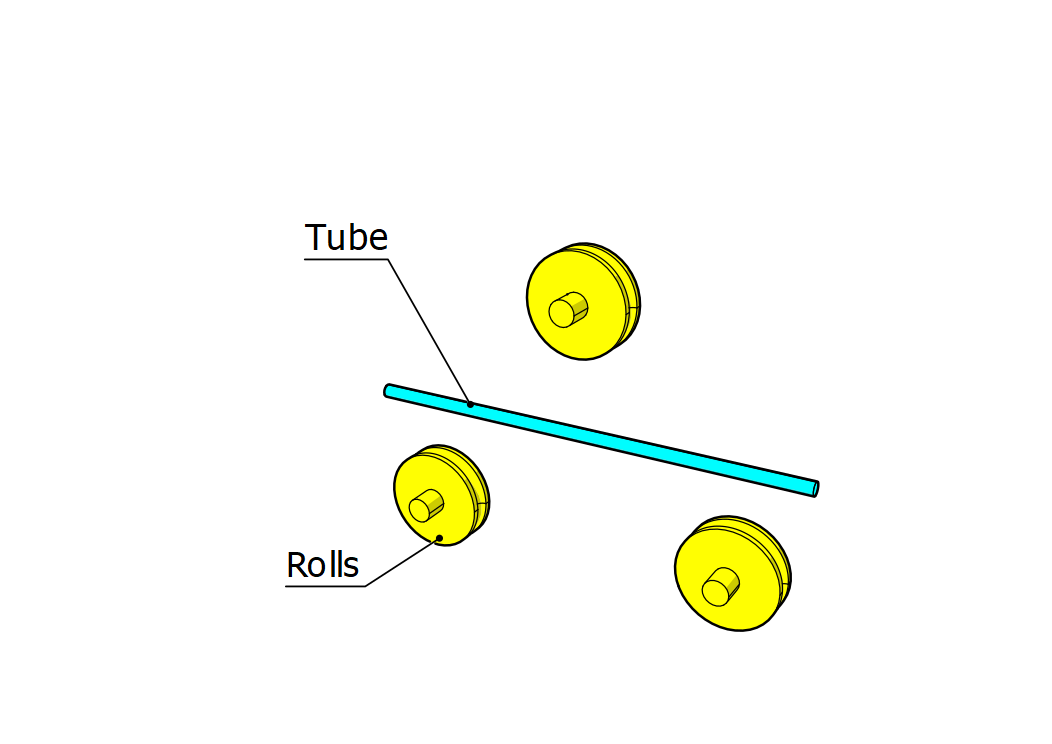

Press bending: It is the most commonly used process. It uses a punch and two dies to restrain the tube at two points. Then the punch makes the bending operation by advancing.

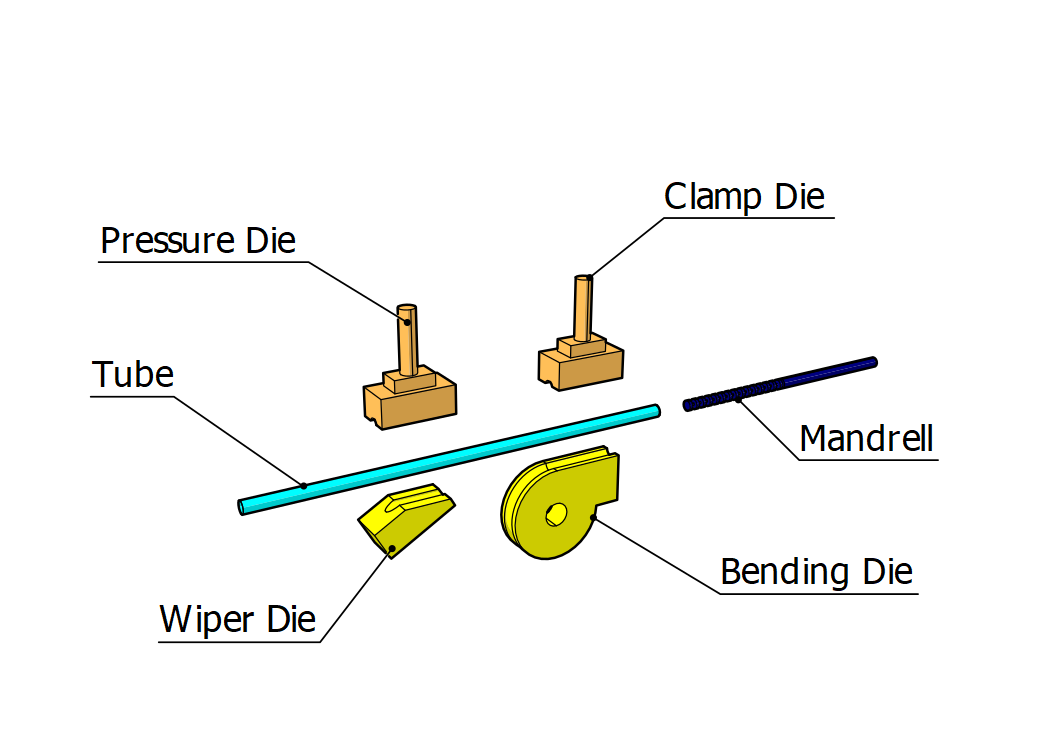

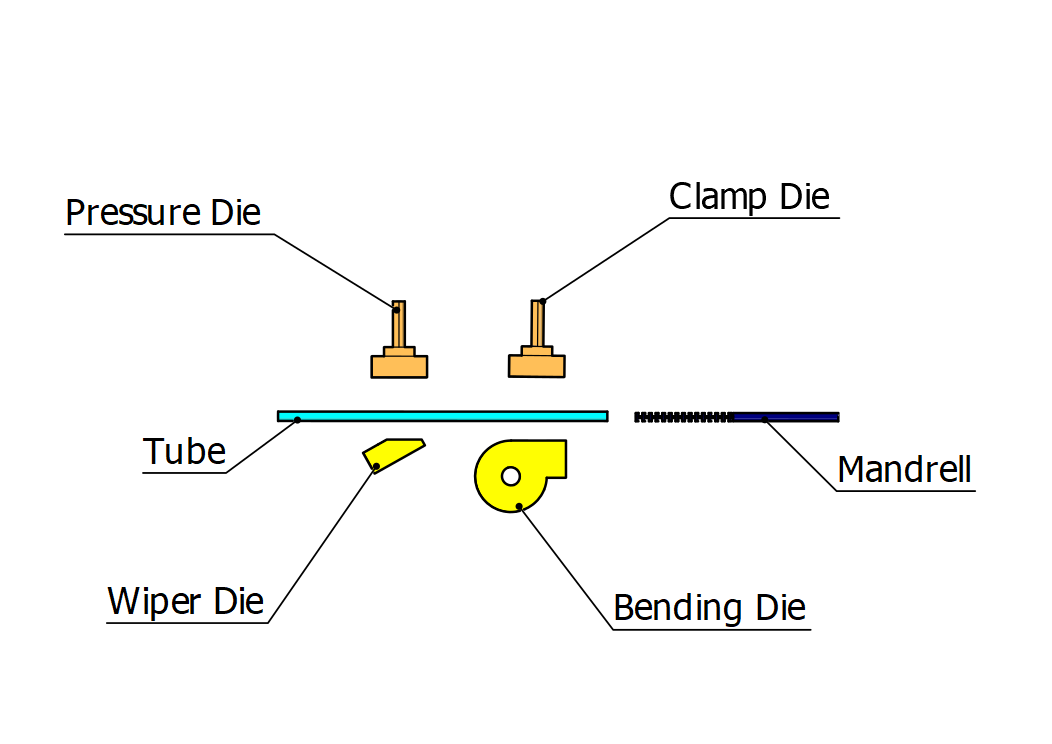

Rotary draw bending: This process uses a clamp that fixes the tube against a q-shaped bending die. Then a pressure die applies pressure on the free tube against a wiper die to perform the bending. A Mandrell is inserted inside the tube to prevent the outer part of the bend from becoming flat.

Heat tube bending: It is used for more rigid materials, and it is made by heating the tube before bending. The bending can be made by a press that enforces the bend, rotatory draw bending, or rolling.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.