Precision Component Manufacturing with CNC Machining

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Norck: Precision Metal Stamping Solutions for Your Production Needs

Norck delivers expert metal stamping services, empowering manufacturers across automotive, electronics, consumer goods, industrial, and other sectors to produce complex components with speed, repeatability, and cost-effectiveness.

Capabilities for Metal Stamping Excellence:

Norck's Engineering Edge: It's About Performance and Precision

Why Choose Norck for Metal Stamping?

It is a process that forms a sheet of metal using a punch and a die. The initial part can be a sheet metal coil or a blank previously cut into a custom shape. See laser and waterjet cutting. Stamping can cut or form sheet metal. It can perform several cuts and bends in a few seconds.

Stamping is widely used in progressive die stamping, a fully automated manufacturing line that transforms sheet metal coils into functional mechanical parts such as enclosures and car bodies. This process is used in automotive manufacturing to fabricate mass-volume car body parts.

Sheet metal components are used in:

• Aircraft's bodies

• Car's bodies

• Consumer electronics

• Biomedical

• Enclosures

• Beverage cans

Generally, sheet metal operations are performed as cold. Norck supplies sheet metal cutting and forming processes such as:

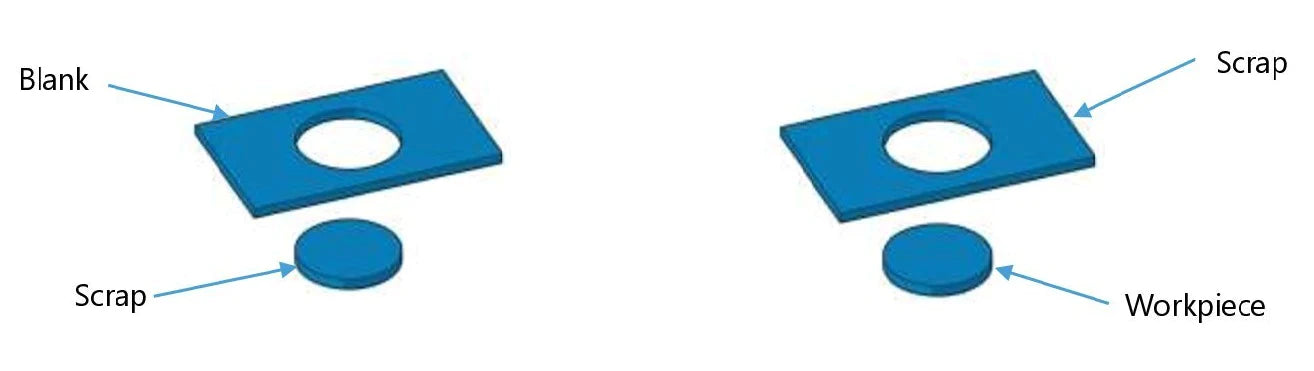

1. Blanking / Punching: Cutting a workpiece from a sheet metal coil using a press (DIE).

The desired result is the difference between blanking and punching (workpiece/scrap).

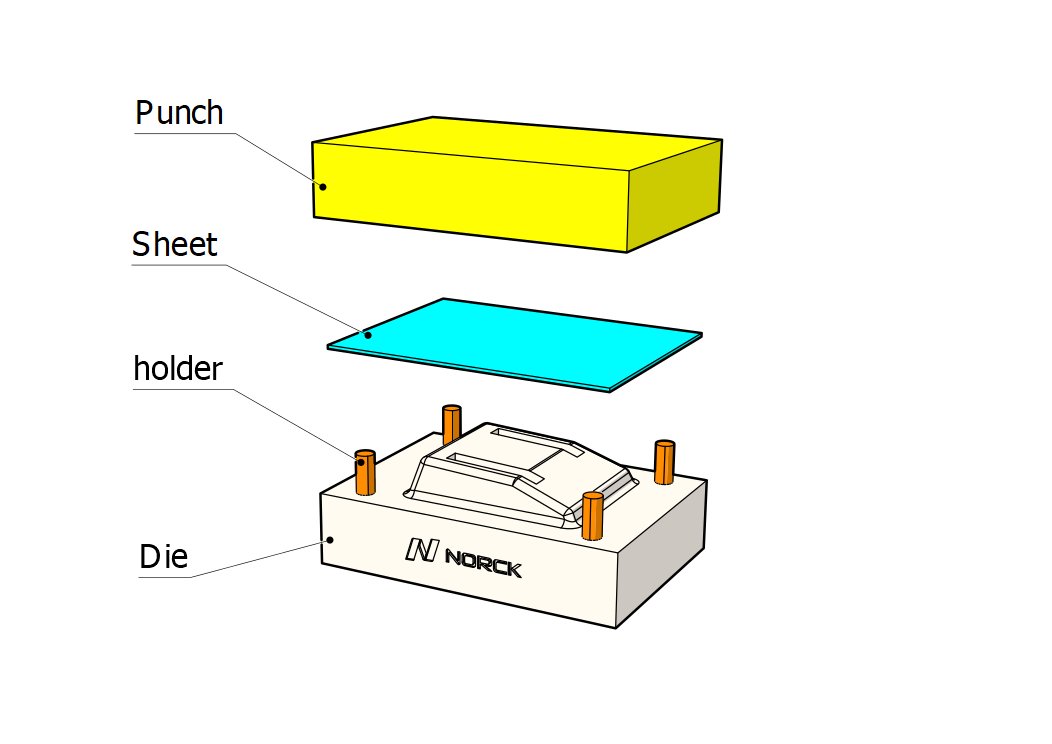

2. Forming : It comprises multiple operations such as blanking, punching, and bending to form a simple or complex shape of sheet metal components. The sheet metal is transformed between a punch and a DIE with male and female shapes of the final workpiece.

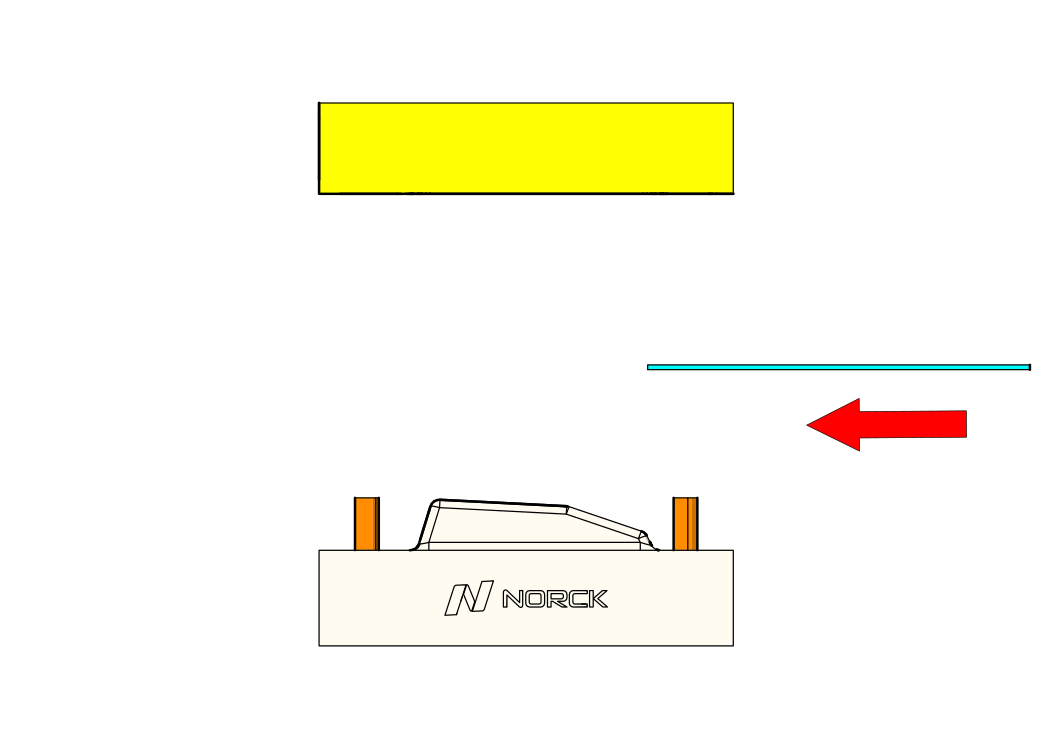

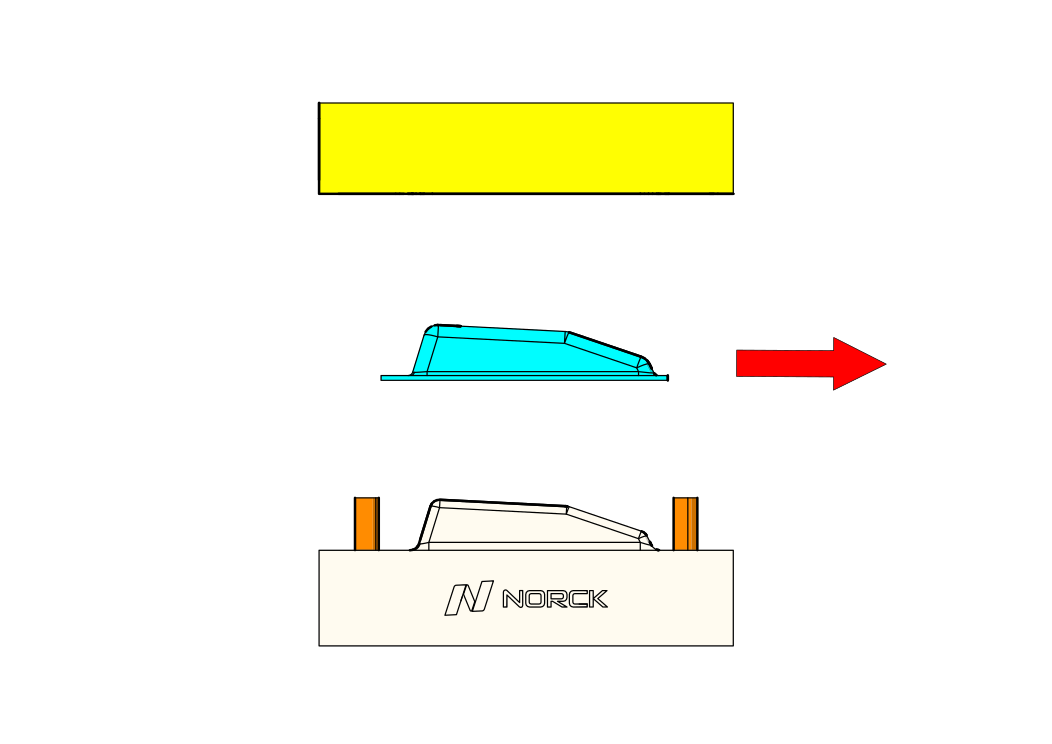

3. Deep drawing : A blank is held between a die and a blank holder, and then it is formed using a punch. The shapes obtained are generally curved parts.

Stamping is typically fabricated using specialized equipment such as stamping or punch press machines. The process can involve several steps, depending on the part's complexity.

• Sheet metal cutting: The first step is to cut the sheet metal to the correct size and shape. It uses various methods such as shearing, sawing, or laser cutting.

• Loading: The sheet metal is then loaded into the stamping press or punch press machine, which holds the metal in place while the stamping process occurs.

• Stamping: The punch, typically a cylindrical or conical shape, is pressed into the die, typically a block with a shaped surface, to cut and shape the metal.

• Unloading: After stamping, the part is extracted from the die, whether manually or using robot arm grippers. The part might undergo additional finishing processes such as painting or plating.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.