Capabilities

- Tight tolerances, complex features, and high-quality finishes on a wide range of metals.

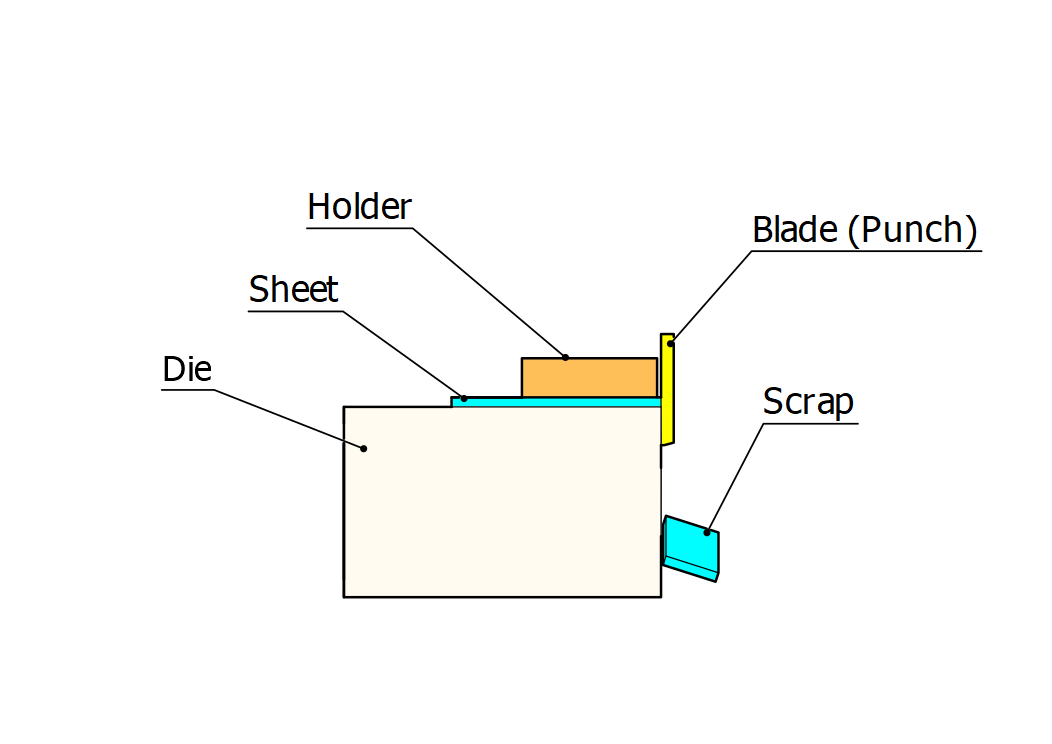

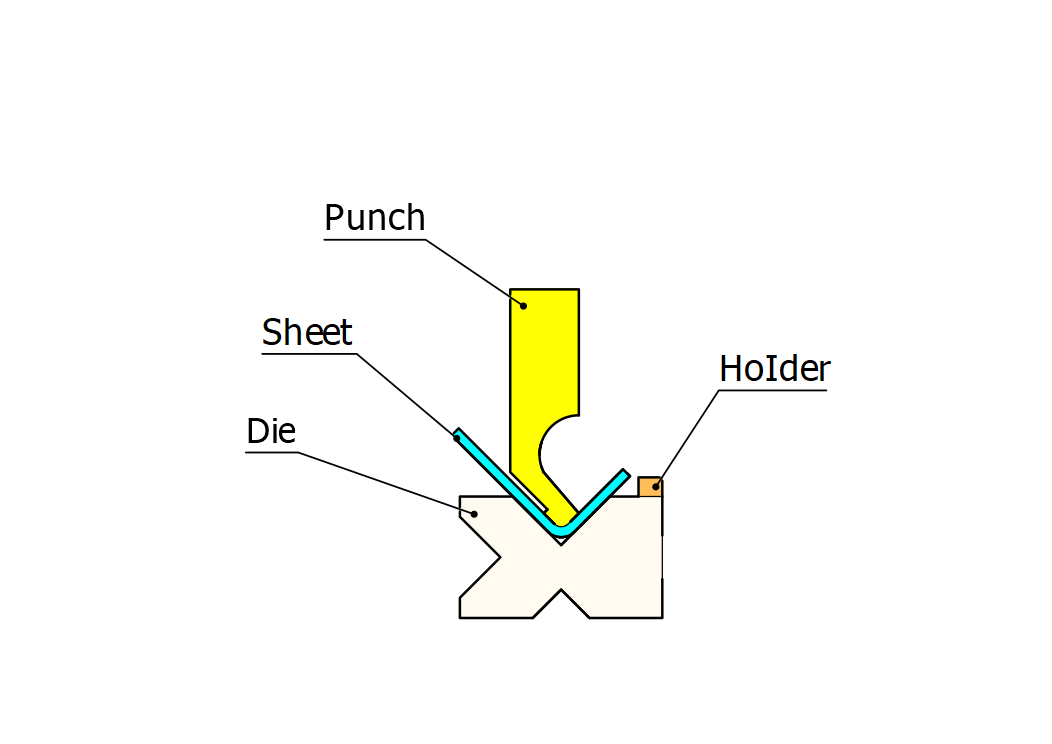

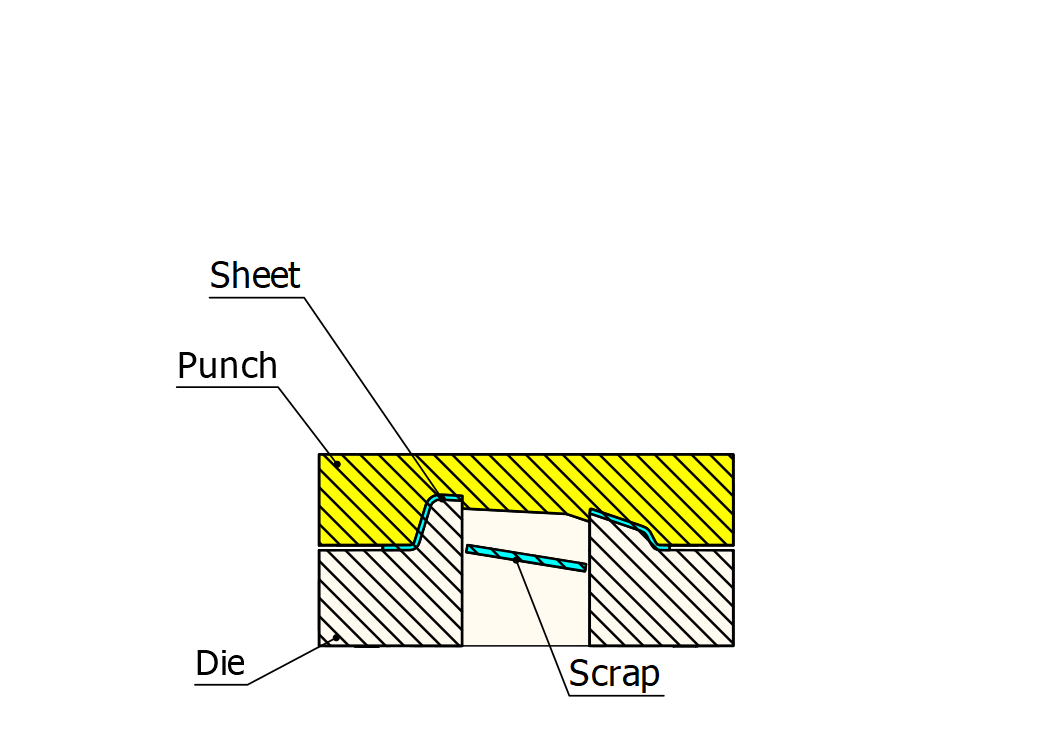

- Precision cutting, forming, welding, and finishing of enclosures and assemblies.

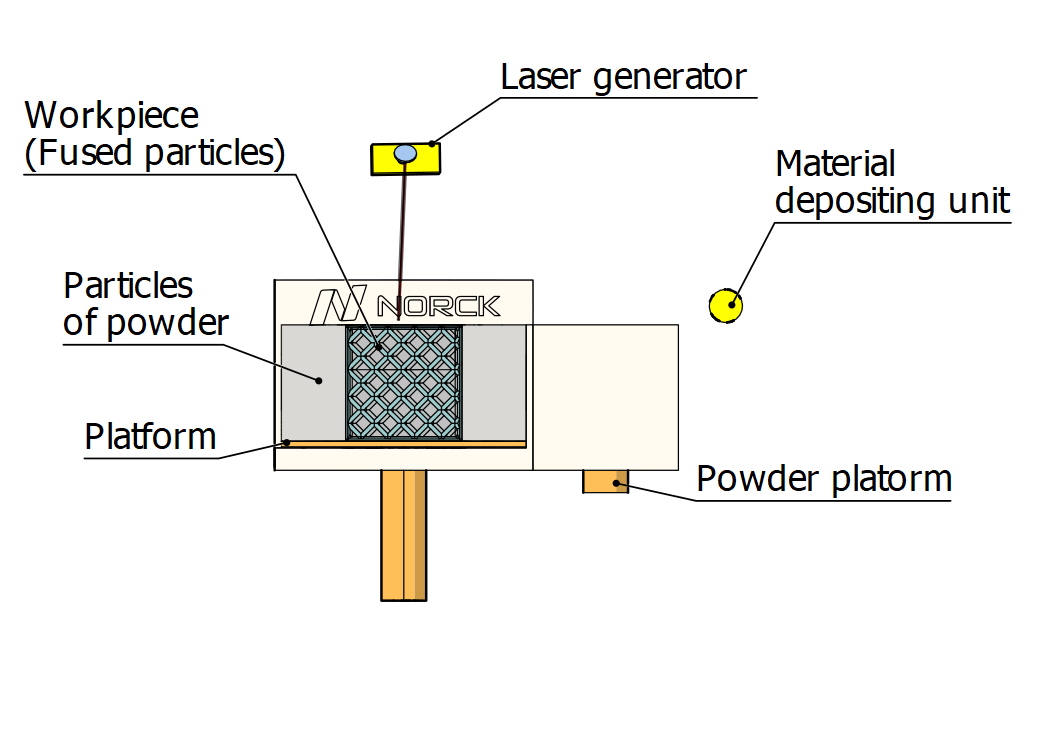

- Fast prototyping and production of intricate, lightweight parts in specialty alloys.

- Casting, forging, heat treatment, plating, and full post-processing integration.

English

English