Capabilities

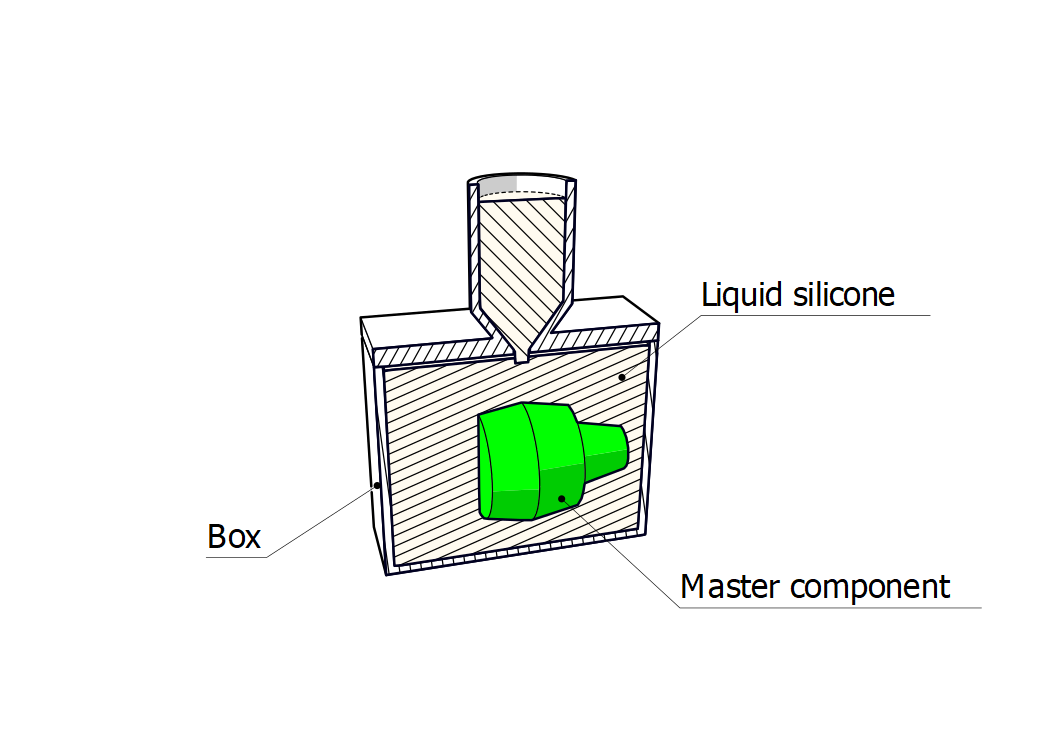

- Master Pattern Creation: CNC, 3D printing, or manual for detailed replication

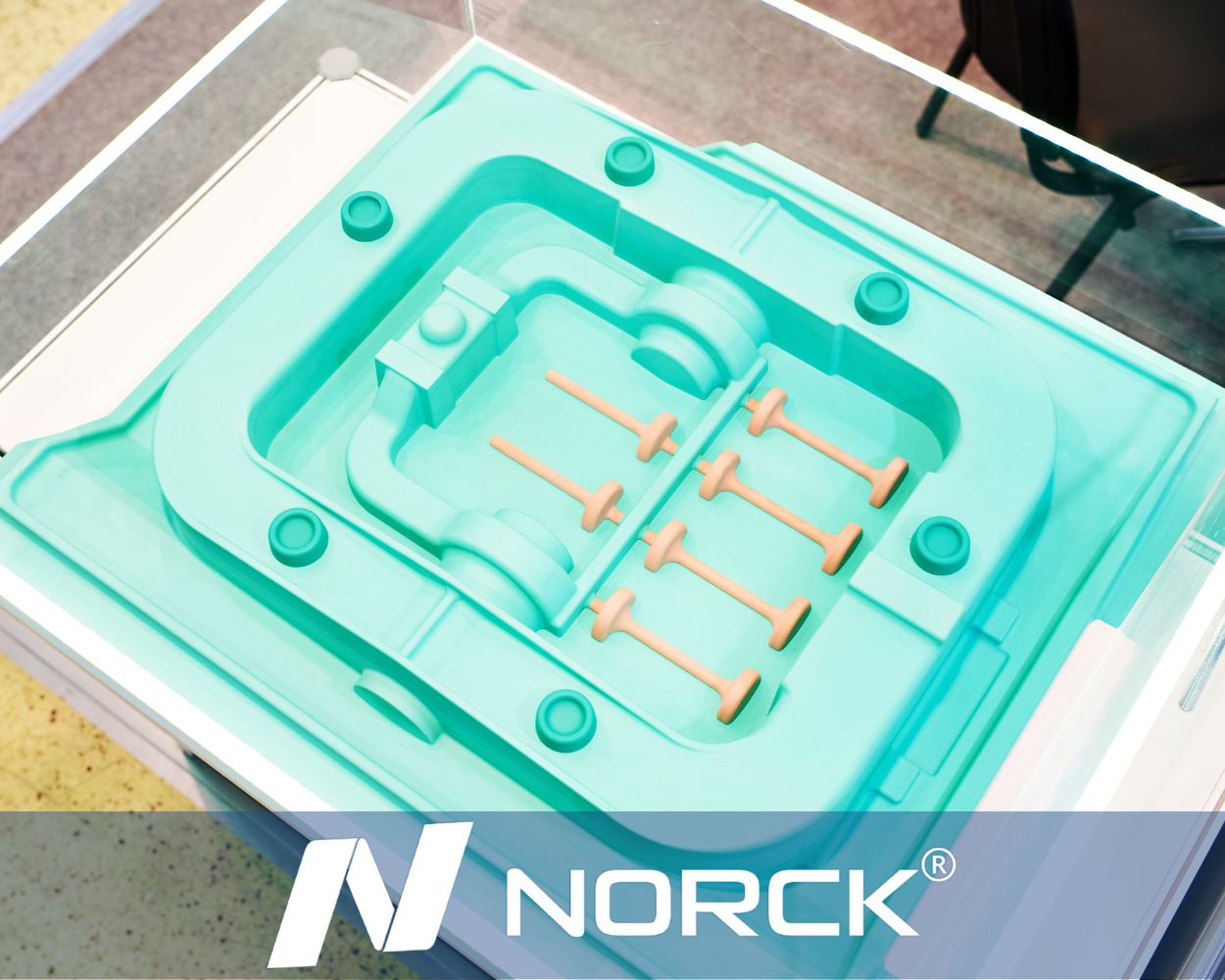

- Silicone Mold Making: Captures intricate textures and features

- Diverse Urethanes: Rigid or flexible, in various colors and hardness levels

- Finishing Services: Painting, inserts, assembly, and polishing

- Scalable Output: From one-off prototypes to medium-batch production

English

English