Rapid Prototyping Services

Rapid prototyping helps turn design ideas into real products quickly and accurately. At Norck, we offer advanced rapid prototyping services using technologies such as CNC machining, 3D printing, sheet metal fabrication, and low volume injection molding. Our efficient rapid prototyping process allows you to create functional parts, test performance, and make design improvements before production. With a wide range of rapid prototyping materials and the latest rapid prototyping technology, Norck helps you accelerate product development and bring innovations to market faster.

What is rapid prototyping?

Rapid prototyping is a set of fabrication techniques with a quick turnaround. It helps turn designs into scaled prototypes as close to the designed model. It is used in the preliminary stages of product development.

Rapid prototyping can be used in conceptual models, functional prototypes, tooling, electronics, and medical industries.

The most used techniques for Rapid prototyping are 3D printing, selective laser sintering (SLS), CNC machining, and sheet metal fabrication.

What are the advantages of using rapid prototyping?

At Norck, rapid prototyping services empower engineers and designers to transform ideas into high-quality, functional parts with speed and precision. The rapid prototyping process helps validate designs early, reducing risks and costly revisions before mass production begins. By leveraging advanced rapid prototyping technology, including CNC machining, 3D printing, and sheet metal fabrication, Norck ensures that each prototype meets exact performance and design requirements.

Key Advantages:

- Faster Development Cycles: Accelerates time-to-market by allowing multiple design iterations in shorter periods.

- Cost Efficiency: Minimizes production waste and reduces the need for expensive tooling.

- Improved Design Validation: Enables testing of form, fit, and function before final manufacturing.

- Material Flexibility: A wide range of rapid prototyping materials such as metals, plastics, and composites ensures realistic and durable prototypes.

Through rapid prototyping in manufacturing, Norck helps clients innovate with confidence, achieving better performance and smoother transitions from concept to production.

Types of Rapid Prototyping

Rapid prototyping services include a variety of advanced manufacturing methods that quickly turn digital designs into real, functional parts. The rapid prototyping process covers multiple techniques such as CNC machining, 3D printing, sheet metal fabrication, and low-volume injection molding. Each method serves different design needs and materials, allowing for flexibility and precision during product development. CNC machining ensures high accuracy, while 3D printing supports complex geometries and faster iterations. Sheet metal and molding techniques are ideal for functional testing and fit analysis. By combining these capabilities, Norck provides complete rapid prototyping services that help customers accelerate innovation, minimize production risks, and confidently move from prototype to final product.

How is it fabricated?

Rapid prototyping techniques can be divided into two categories:

- Compressive manufacturing: by forming a base material into a shape such as 3D printing

- Subtracting manufacturing: by removing material such as CNC machining and sheet metal fabrication

Norck offers three types of rapid prototyping, 3D printing, CNC machining, and sheet metal fabrication.

1. 3D printing

The most used process is 3D printing which is an additive manufacturing process. In 3D printing, there are types such as:

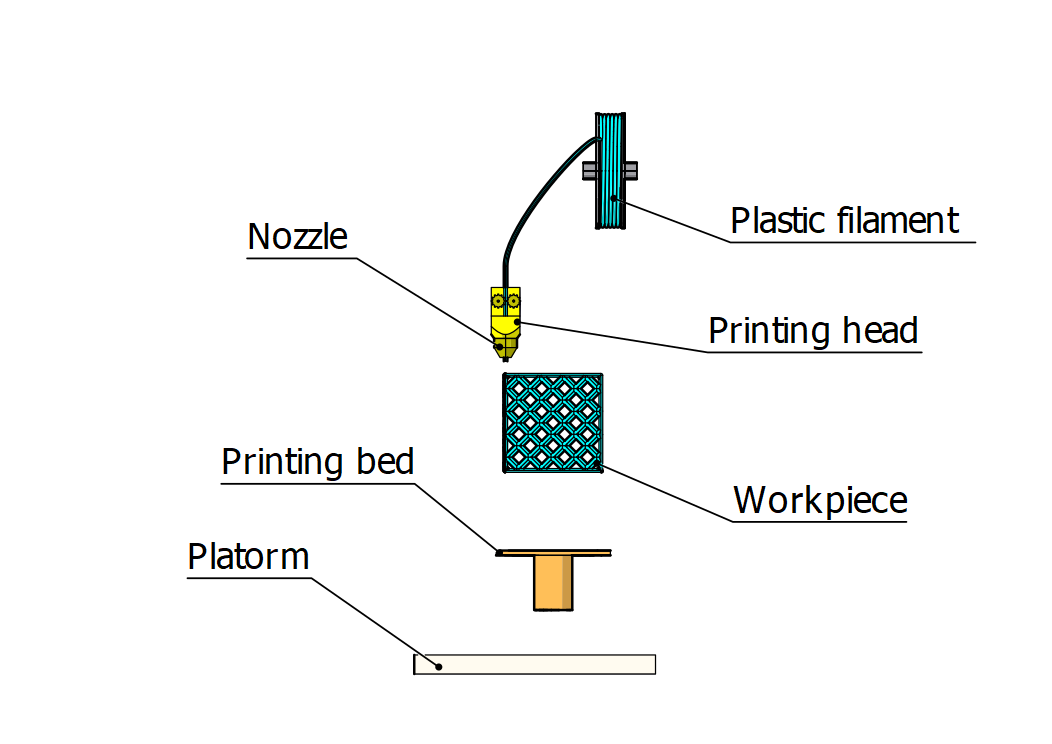

a. Fused deposition modeling (FDM):

FDM is the most popular and most cost-effective of the 3D printing processes. It uses a filament of a thermoplastic material such as PLA AND ABS. The filament passes through a hot nozzle that melts it and using a computer-controlled system, the nozzle moves along two axes and deposits the melted material on a platform. When a whole layer of the desired shape is deposited, the nozzle moves up to deposit the next layer. Once the 3D printed model is finished, it can be removed from the platform, any excess material or burrs is removed, and surfaces are smoothed.

Fused DepositionModeling

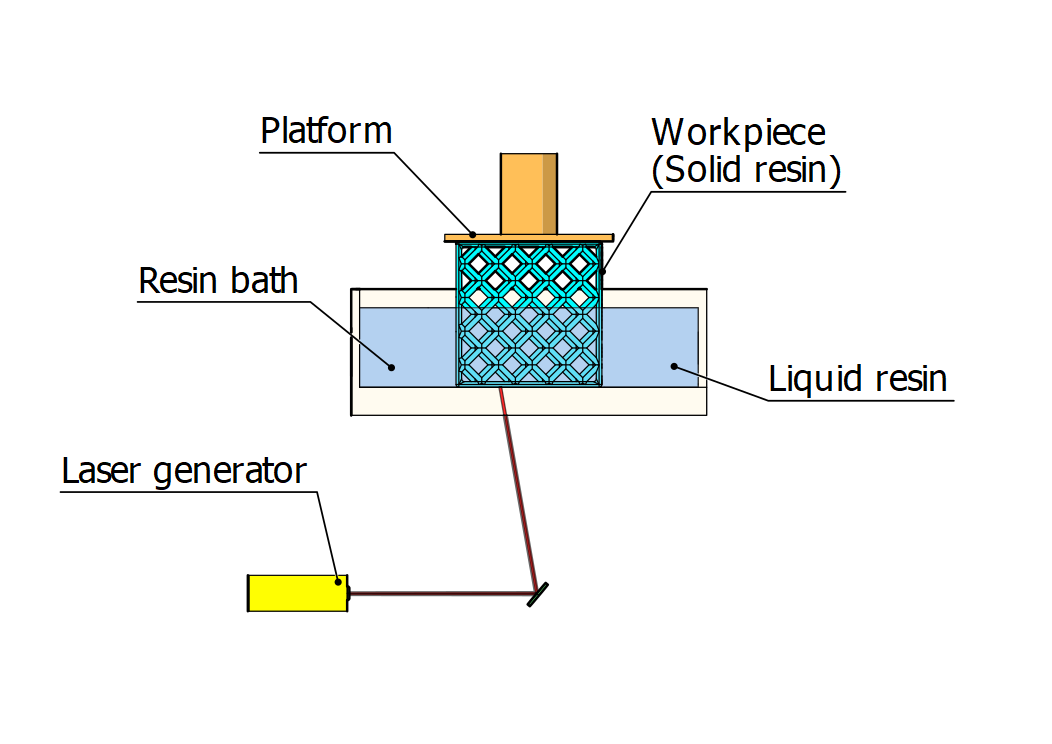

b. Stereolithography (SLA):

SLA 3D printing uses a bath of UV-sensitive liquid resin and an ultraviolet laser beam to solidify the liquid layer by layer. The laser beam is computer controlled. The solid layer is pulled up, and the next layer is processed. Once the 3D printed model is finished, it can be removed from the platform and submerged in isopropyl alcohol to remove any excessive resin. Then the model gets exposed to passive UV light. SLA models are less rigid than FDM printed models.

Stereolithography

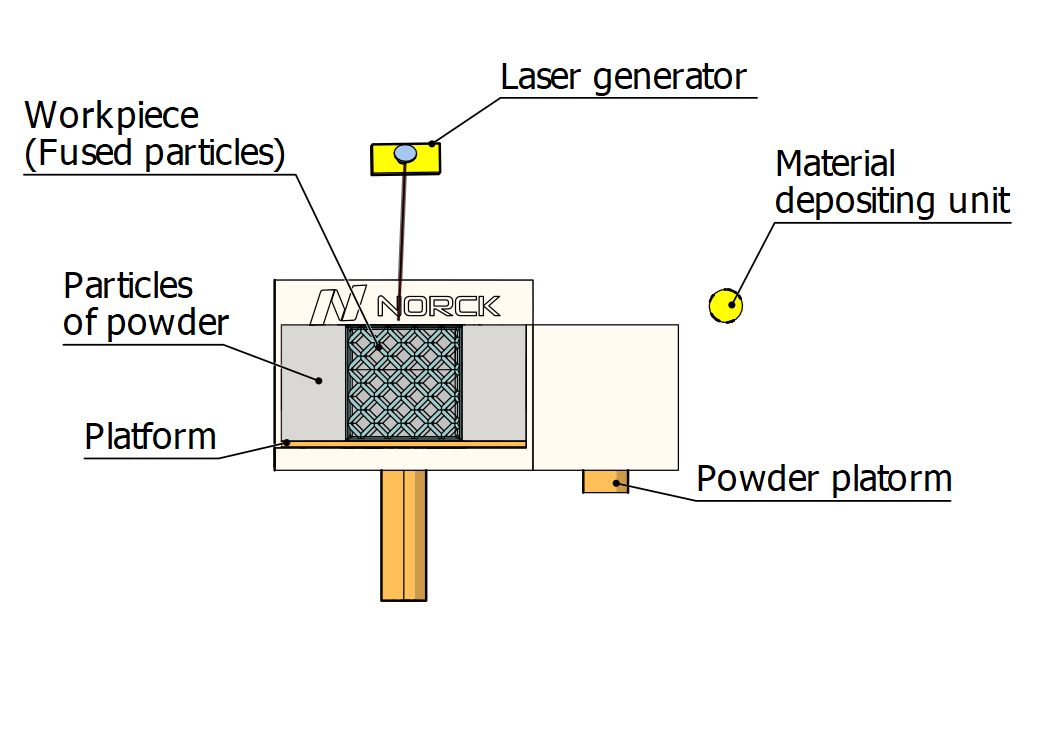

c. Selective laser sintering (SLS):

It uses a laser to sinter a bed of powder-based materials (Metal, resin, or polymer) to turn the powder into solid products. Materials used in SLS are more fragile than those used in FDM or SLA. Printed models can be finished using sanding, polishing, or spray coating. SLA parts have higher accuracy and smoother surfaces than SLS and FDM.

Selective laser sintering

Comparison between the four techniques can help you narrow your choice, or contact us to get more information:

|

|

Dimension Accuracy (mm) |

Layer height |

Build size |

|

FDM |

±0.2 |

0.05 to 0.2 |

900x600x900 |

|

SLA |

±0.02 |

0.05 to 0.15mm |

1500x750x500 |

|

SLS |

±0.3 |

0.1 to 0.12 |

550x550x750 |

Parts and assemblies should follow specific design rules to be cut properly. Norck offers engineering services that will help you confirm your design for 3D printing.

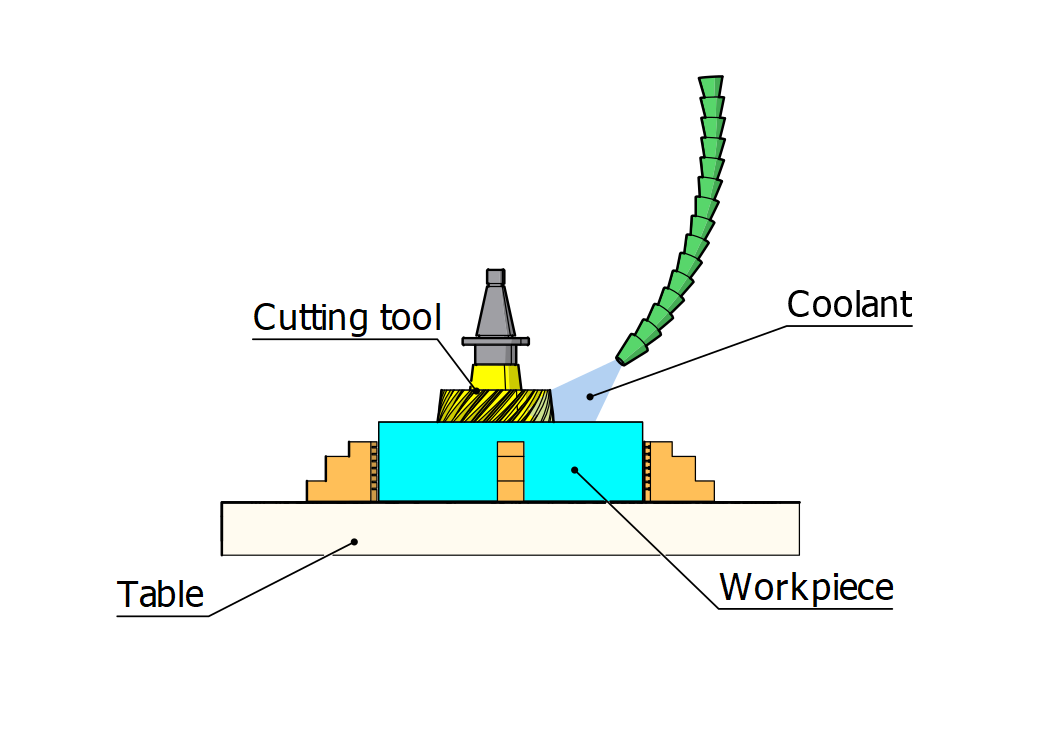

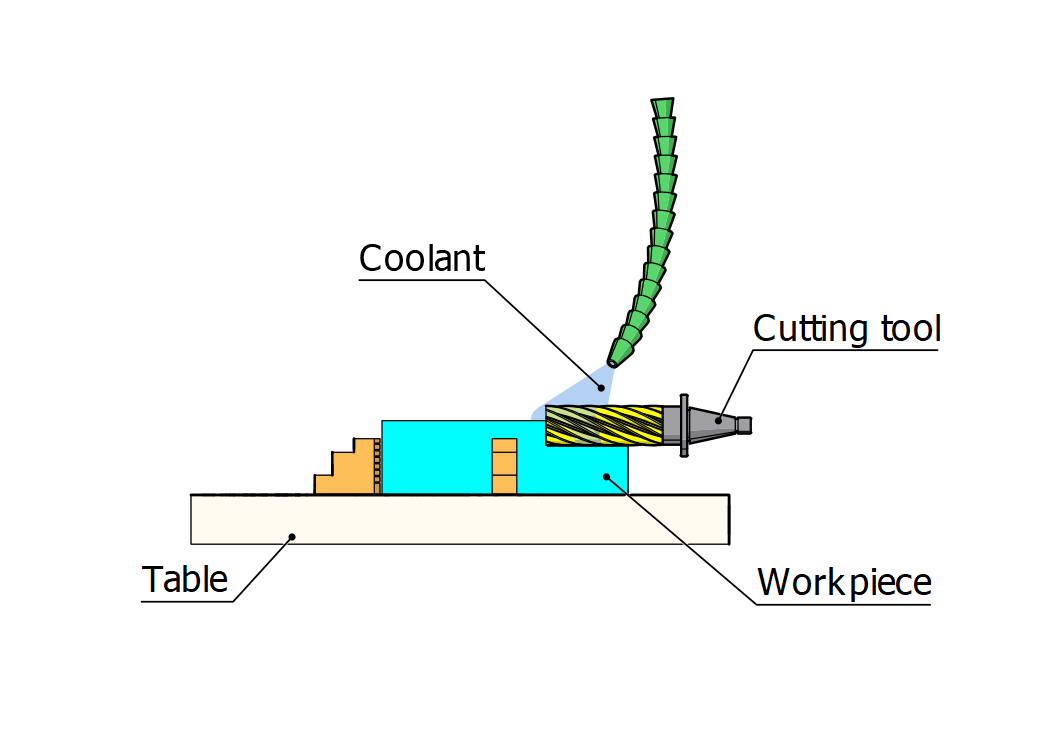

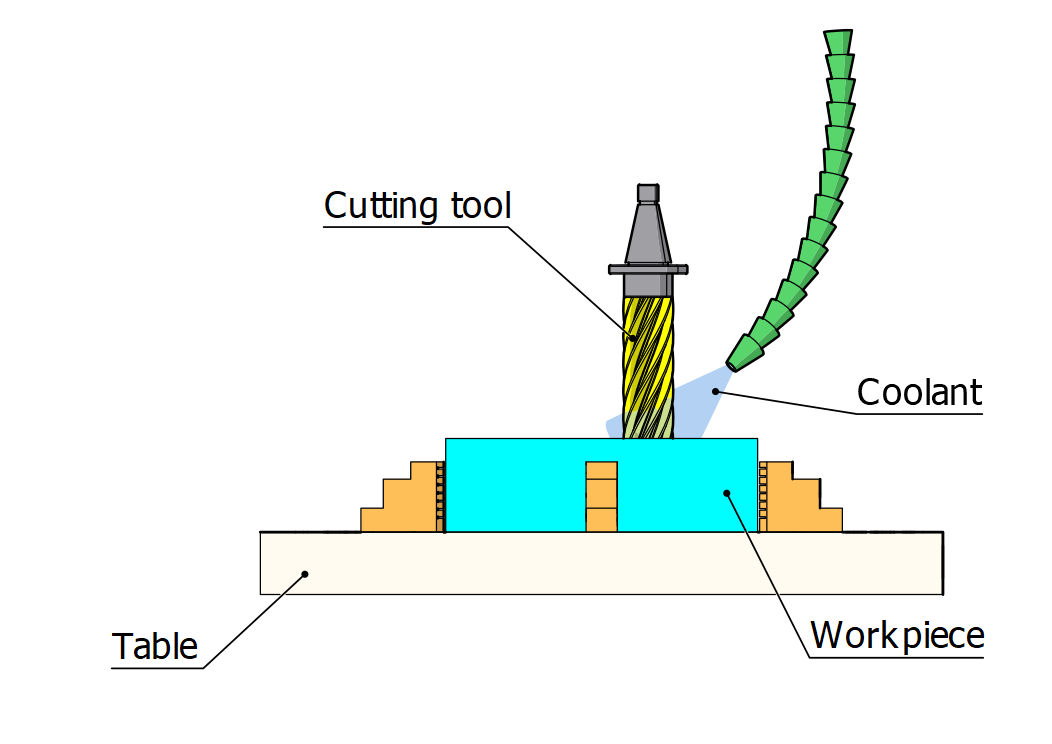

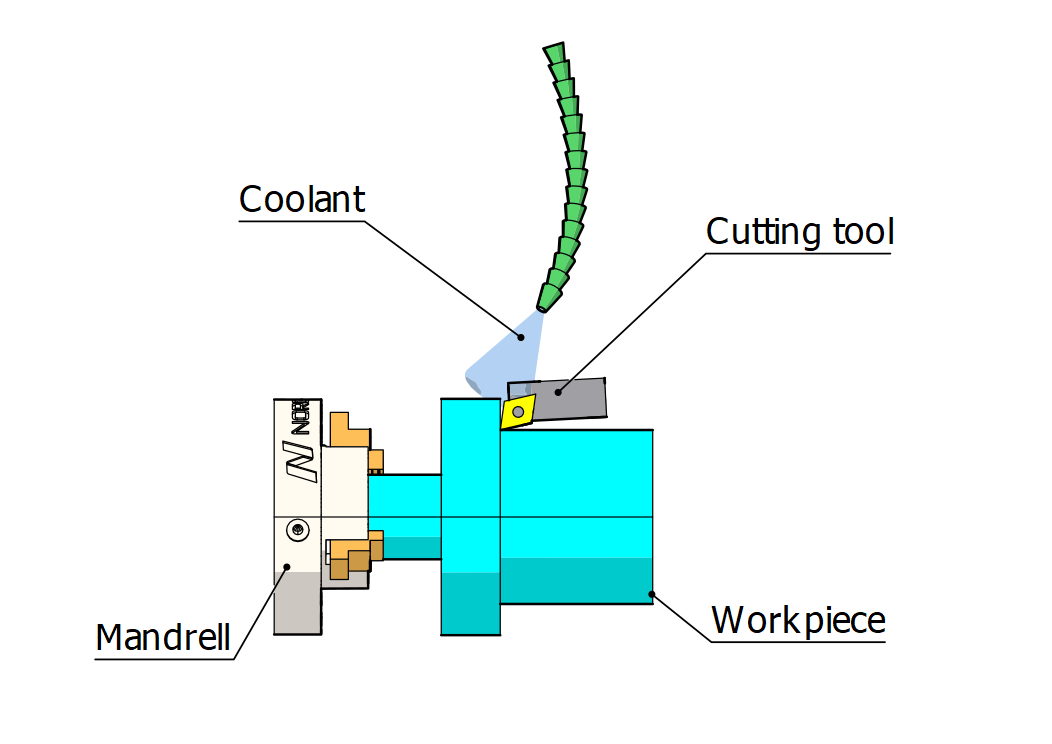

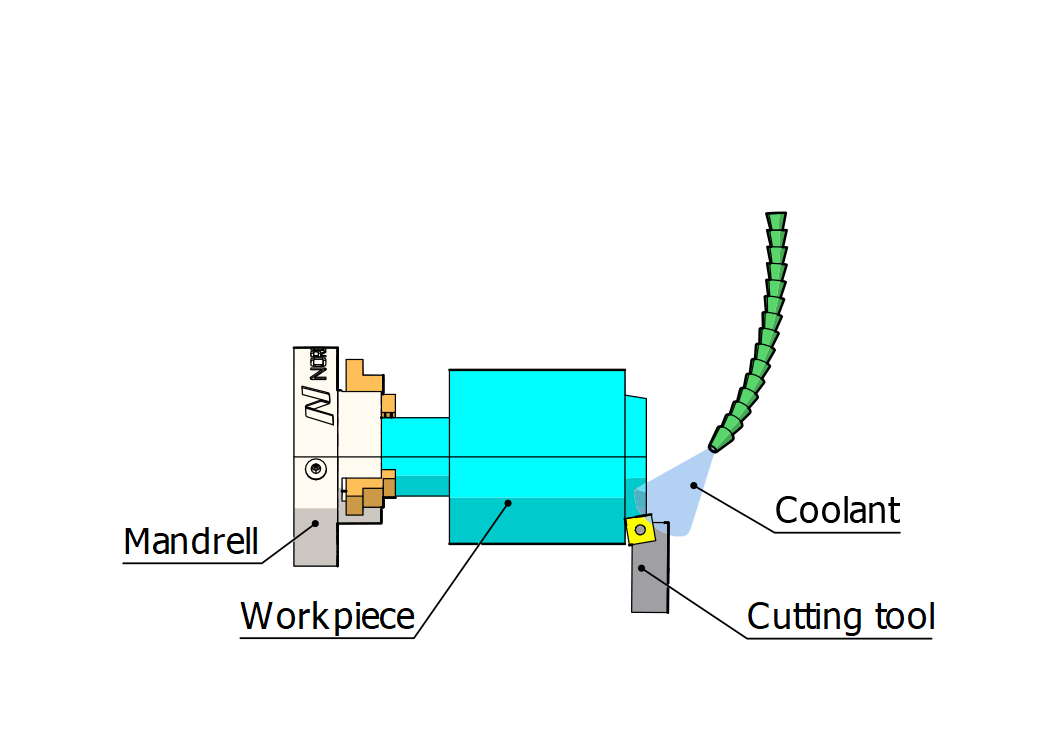

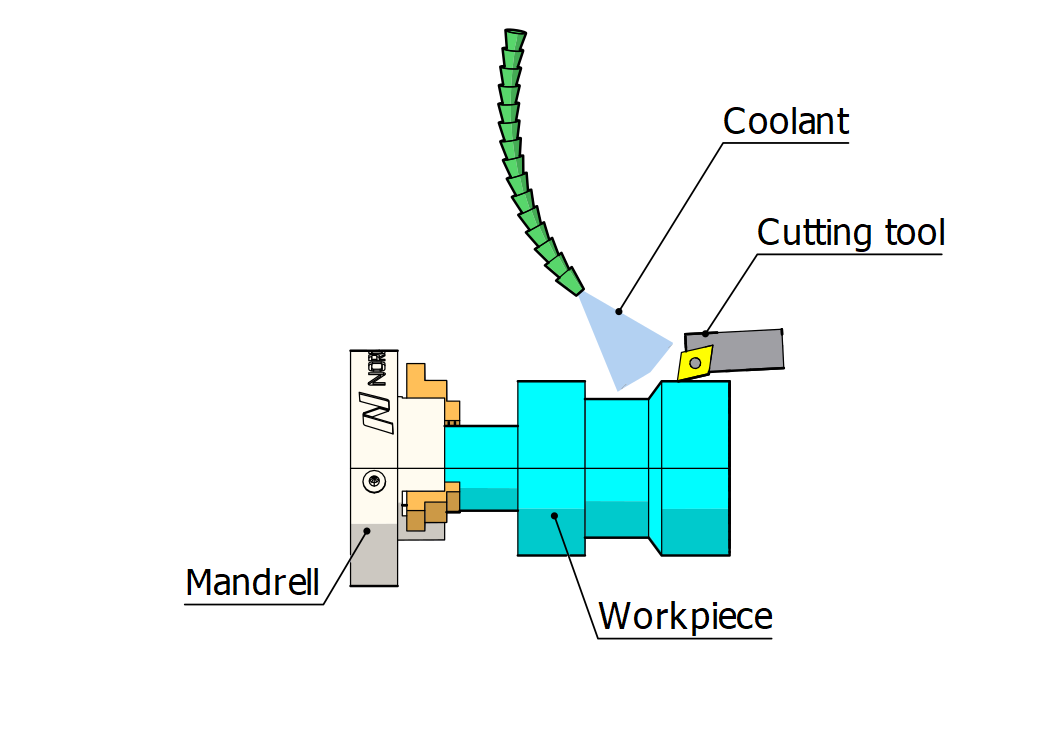

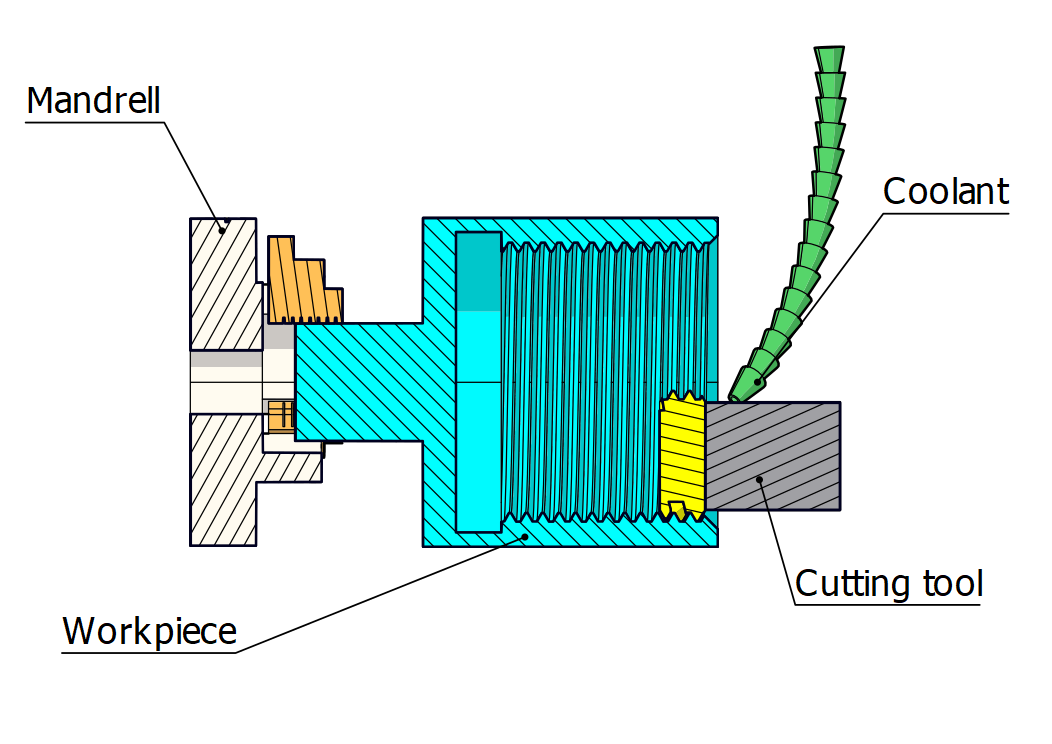

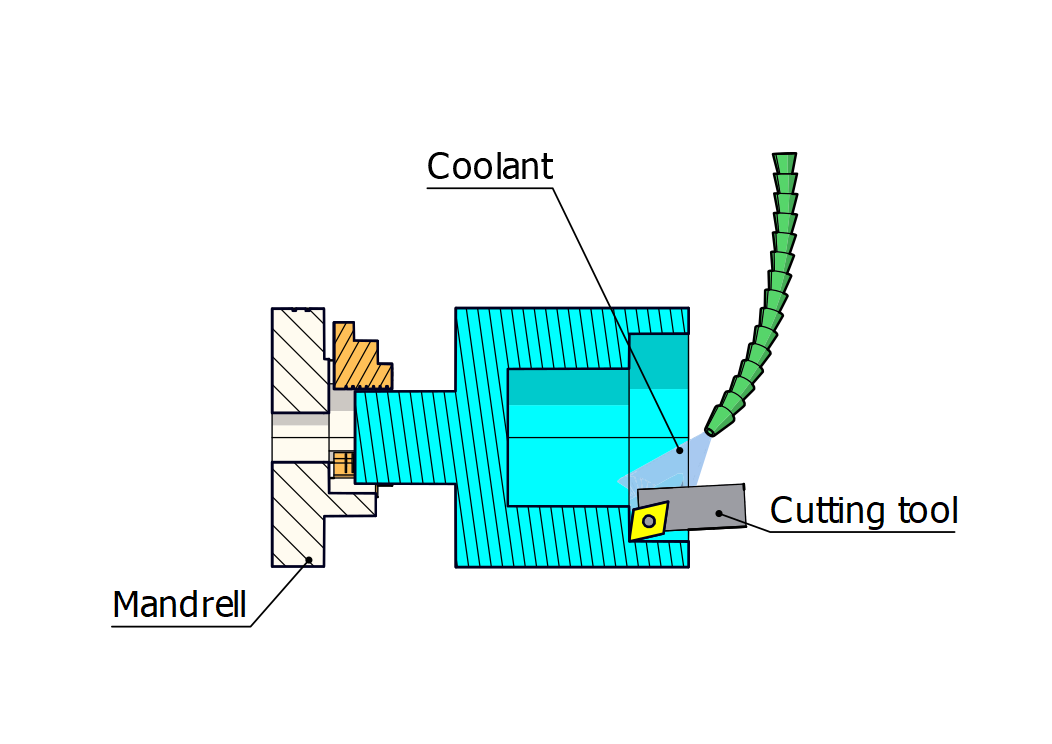

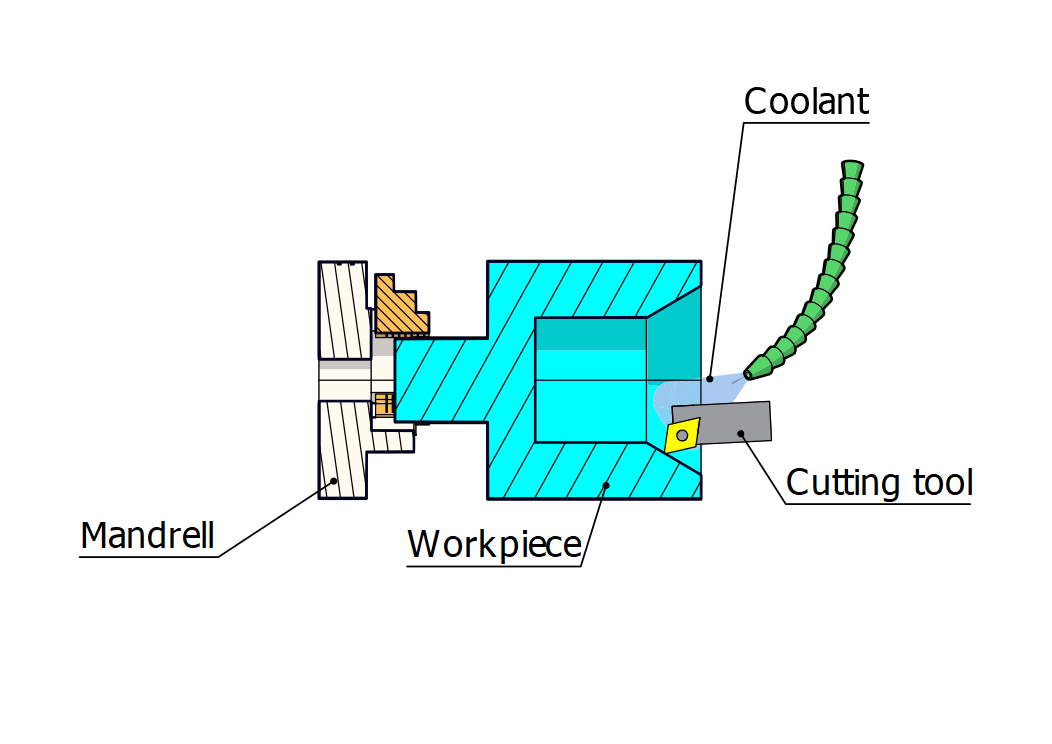

2. CNC Machining

CNC machining designates a subtractive process in which operations like milling, turning, and drilling is performed to produce the designed parts by removing layers of material from the primitive material shapes. The advantage of traditional machining is that CNC machining uses computer-controlled machines, which means more accuracy, higher fabrication speed, and low labor cost.

Refer to the CNC machining and Design rules for further information.

Norck: Accelerate Your Development with Expert Rapid Prototyping

Norck delivers fast, accurate, and cost-effective prototypes using CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our skilled engineers and advanced technologies ensure your designs are validated quickly, exceeding expectations across diverse industries.

Expanded Capabilities:

At Norck, we combine advanced manufacturing technologies with engineering precision to deliver functional and test-ready prototypes across diverse materials and processes. Our expanded capabilities ensure that every stage from concept validation to pre-production is fast, flexible, and optimized for quality results.

- 3-axis, 5-axis, and multi-axis milling for simple to highly complex geometries.

- CNC turning for precision cylindrical prototypes with tight tolerances.

- Wide range of metals (aluminum, steels, alloys) and engineering plastics.

- Surface finishes tailored to testing needs (rough for fit checks, fine for functional evaluation).

3D Printing (FDM, SLA, PolyJet, MJF):

- FDM: Cost-effective for early iterations, large prototypes, and jigs/fixtures

- SLA: High-resolution for intricate details and smooth surface finishes.

- PolyJet: Multi-material and full-color prototypes for realistic appearance and overmolding.

- MJF: Fast production of functional nylon parts.

- Bending, forming, and cutting of various metals and thicknesses.

- Welding and assembly of multi-component enclosures and brackets.

- Surface finishing options (powder coating, anodizing) for representative prototypes.

- Rapid tooling for cost-effective short runs with production-grade thermoplastics.

- Overmolding and insert molding capabilities for complex assemblies.

- Essential for testing material behavior, gate placement, and draft analysis.

- Mechanical assembly of multi-component prototypes for fit and function testing.

- Integration of electronics, sensors, and other elements.

- Bonding, fastening, and finishing for a complete prototype solution.

Why Norck for Rapid Prototyping?

- Problem-Solving Approach: We understand your pain points and tailor the right methods for your goals.

- Rapid Iteration Support: Get multiple versions quickly to refine designs and improve functionality.

- Material Expertise: Guidance on choosing production-equivalent materials for realistic testing.

- Design for Manufacturability (DFM): Early feedback to avoid costly production changes later.

- Single-Source Responsibility: Streamlined prototyping and assembly process, saving time and coordination.

Applications of Rapid Prototyping in Different Industries

Rapid prototyping services have become essential across industries that demand speed, precision, and innovation. In sectors like automotive, aerospace, and medical technology, the rapid prototyping process enables engineers to create functional models for performance testing and design optimization. From aerodynamic car components to medical implants and aerospace fittings, prototypes are produced using high-precision rapid prototyping technology such as CNC machining, 3D printing, and sheet metal fabrication.

In rapid prototyping in manufacturing, companies gain the ability to evaluate materials, geometries, and assembly methods before committing to mass production. By utilizing advanced rapid prototyping materials, such as lightweight alloys and durable polymers, Norck helps clients achieve shorter development cycles, improved product performance, and faster market entry—making innovation more efficient across diverse industries.

What Are the Differences Between Rapid Prototyping and Manufacturing Methods

Rapid prototyping services focus on speed, flexibility, and design validation, while traditional manufacturing emphasizes efficiency and scalability in mass production. The rapid prototyping process uses advanced rapid prototyping technology such as CNC machining, 3D printing, and sheet metal fabrication to produce functional prototypes quickly, often with a variety of rapid prototyping materials like plastics, metals, and composites. These prototypes help identify design flaws and improve product functionality before final production.

In contrast, rapid prototyping in manufacturing serves as a bridge between concept and large-scale production. While manufacturing methods prioritize cost optimization and consistency, rapid prototyping allows for creative exploration and iterative development. Together, these approaches create a seamless path from innovative design to reliable, high-quality manufacturing.

OUR SERVICES

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

English

English