Available 3D Printing Materials

Norck offers a wide range of advanced materials through its professional 3D printing service, enabling engineers and manufacturers to choose the ideal option for both prototypes and end-use parts. These materials play a critical role in modern production decisions, ensuring strength, accuracy, and design flexibility across multiple industries. Our selection supports everything from aesthetic concept models to high-performance functional components, allowing teams to accelerate innovation with confidence.

PLA

A cost-effective, eco-friendly material ideal for fast prototyping and visual models.

ABS

A durable engineering plastic offering heat resistance and strength for functional parts.

Nylon

A high-performance material with excellent toughness, flexibility, and wear resistance.

TPU

A rubber-like material providing elasticity, impact resistance, and long-term durability.

Resin

Perfect for high-detail models, offering exceptional surface quality and precision.

Metal 3D Printing

Enables strong, industrial-grade components using materials like stainless steel, aluminum, and titanium.

Industries Norck Serve With Our 3D Printing Service

Norck provides cutting-edge 3D printing services to a diverse range of industries, including aerospace, defense, automotive, robotics, electronics, medical devices, consumer products, and industrial manufacturing. Our custom 3D printing capabilities support rapid prototyping, functional testing, and low-volume production, helping each sector reduce development time and accelerate product launches. With reliable quality and fast turnaround, Norck is a trusted partner for companies aiming to innovate with speed and precision.

Cost Structure of 3D Printing Services

The cost structure of Norck’s 3D printing services is designed to be transparent and easy to understand. Factors such as material type, part geometry, production technology, and quantity influence the overall 3D printing services price. Using our online 3D printing service, customers can upload their files, receive an instant cost estimate, and proceed with secure payment options. Without providing fixed pricing, Norck ensures that each quote reflects real production requirements, giving customers a fair, accurate, and efficient ordering experience.

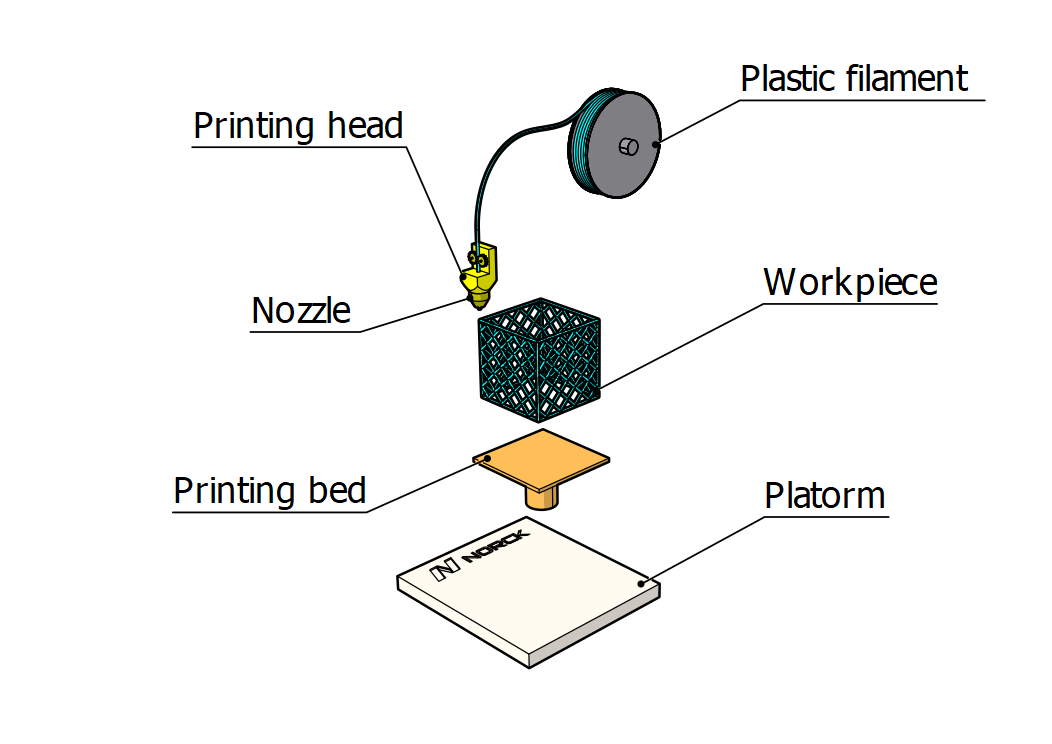

Custom 3D Printing Solutions by Norck

Norck delivers fully tailored custom 3D printing solutions designed to meet the unique needs of engineering teams and product developers. Whether creating complex prototypes, durable functional components, or metal parts with intricate geometries, our advanced capabilities ensure precision and repeatability at every stage. Supported by expert engineering guidance and on-demand production, Norck helps companies streamline development, reduce risk, and bring high-performance products to market faster.

English

English