Engineering Expertise That Delivers

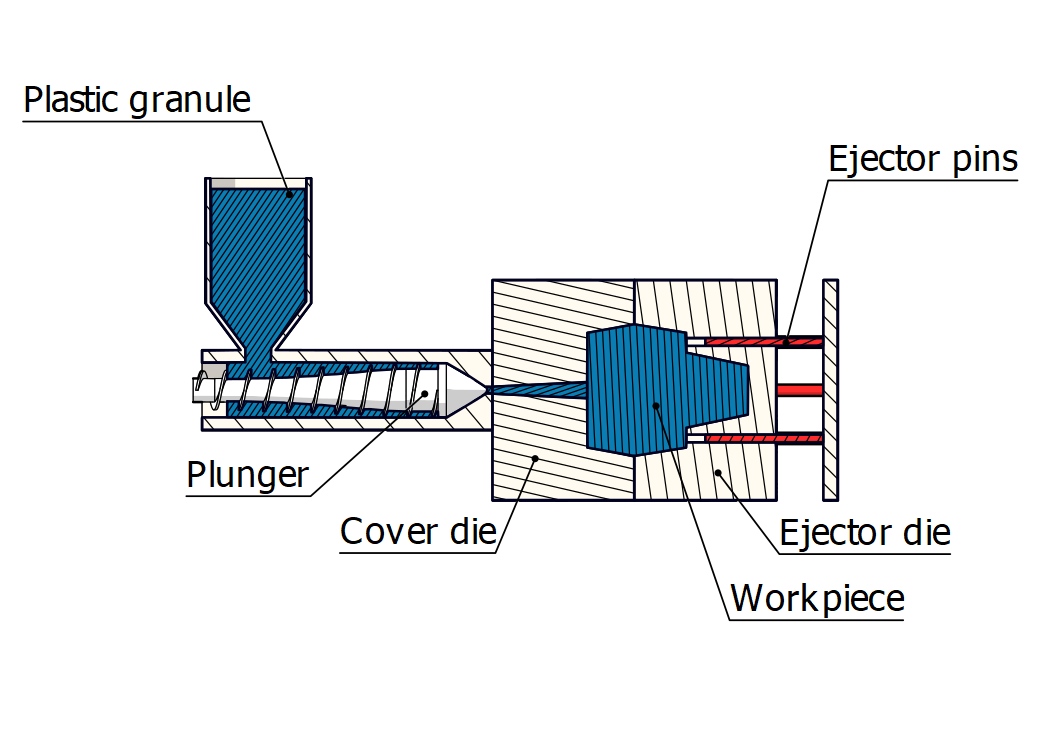

- Design for Manufacturability: We assess your design for optimal compatibility with various production methods.

- Material Selection: Tailoring plastic choices to meet performance, cost, and environmental needs.

- Moldflow Simulation: Preventing defects and optimizing mold design before production.

- Quality Assurance: From dimensional checks to material and function validation—every step is covered.our design for optimal compatibility with various production methods.

English

English