Capabilities

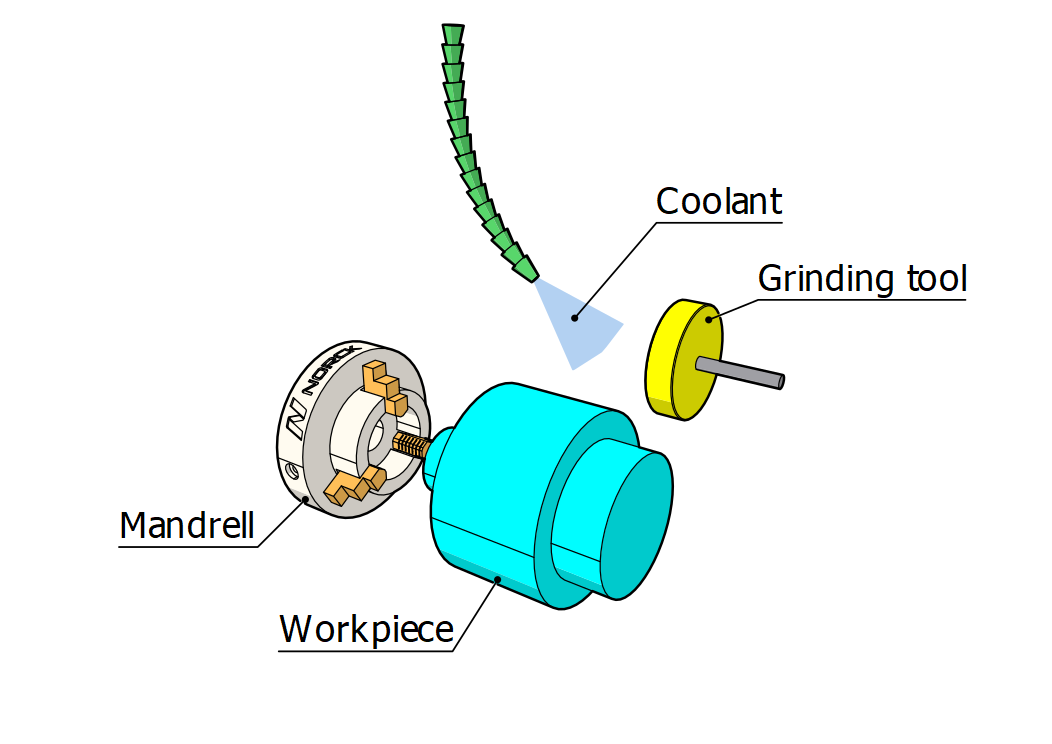

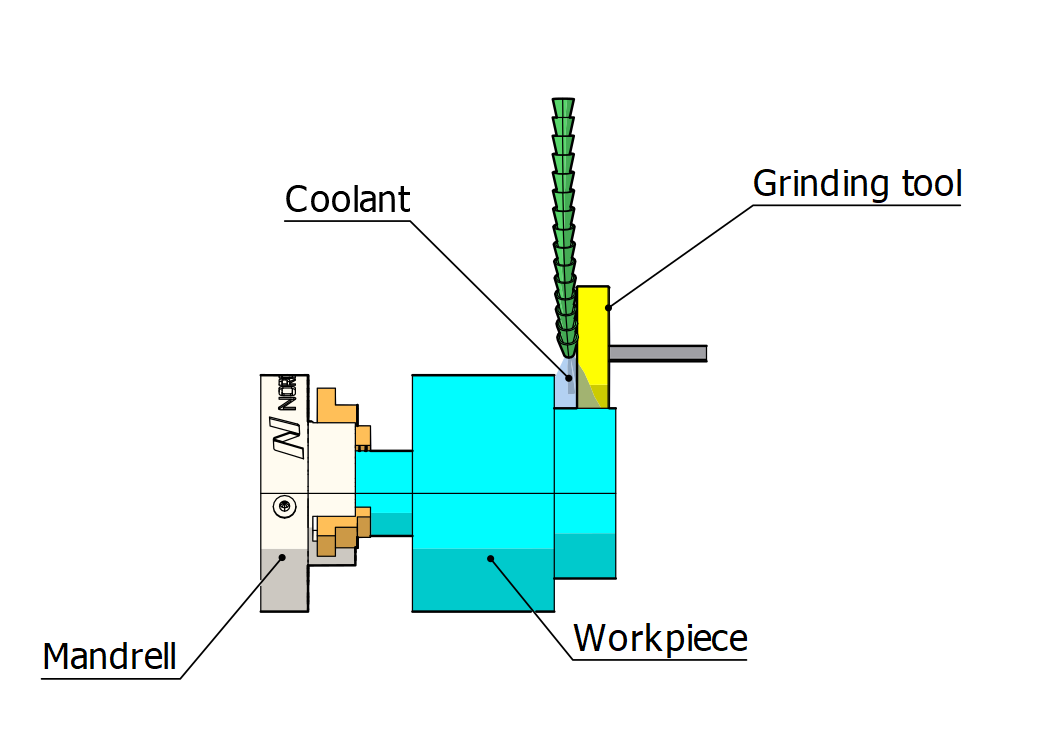

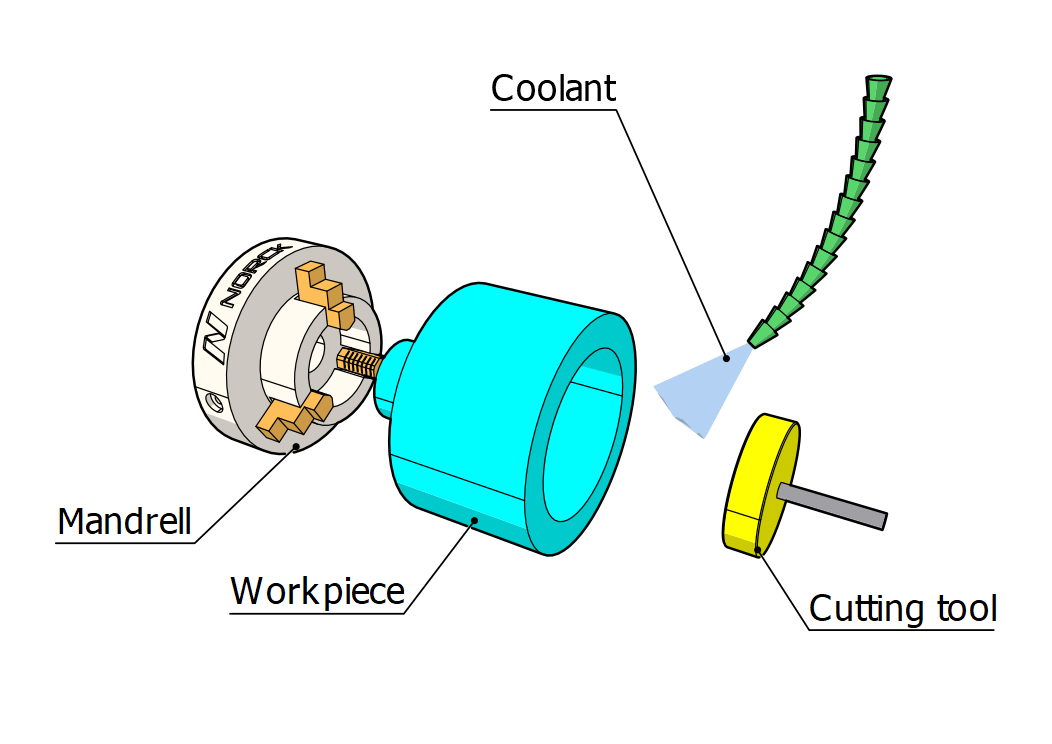

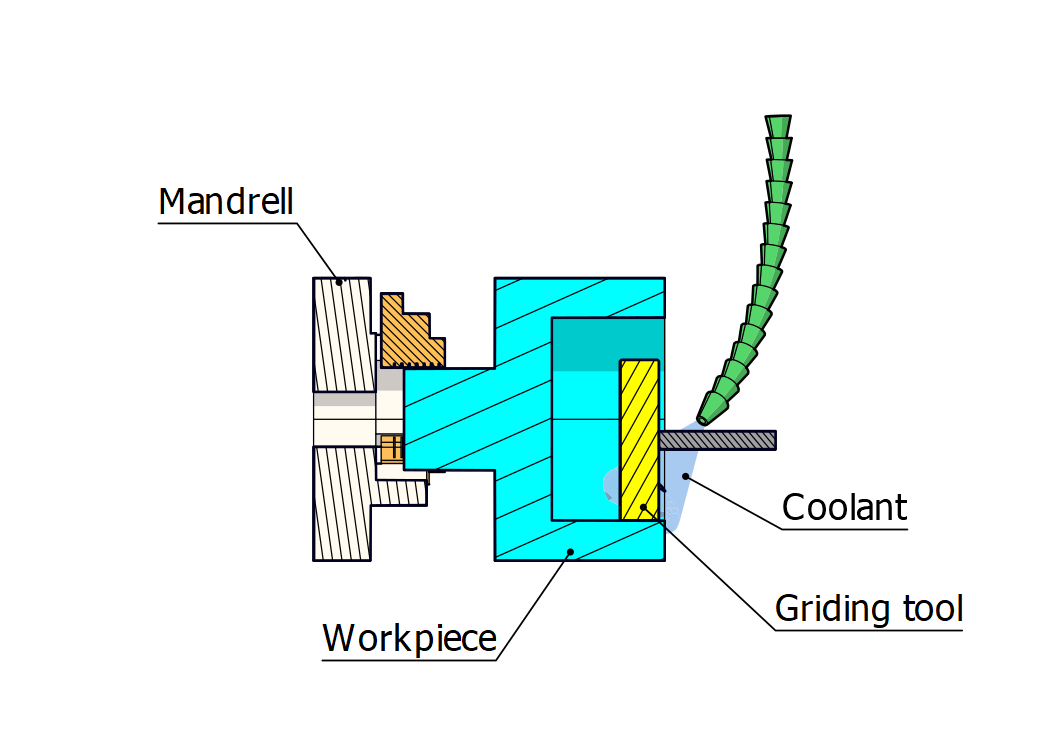

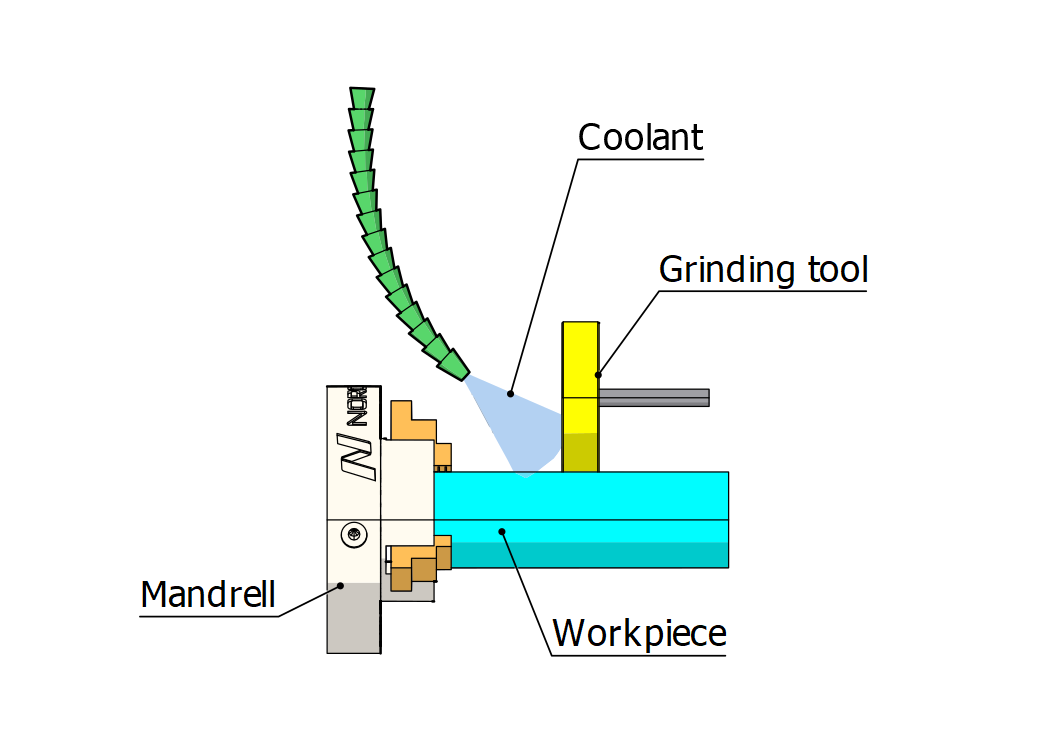

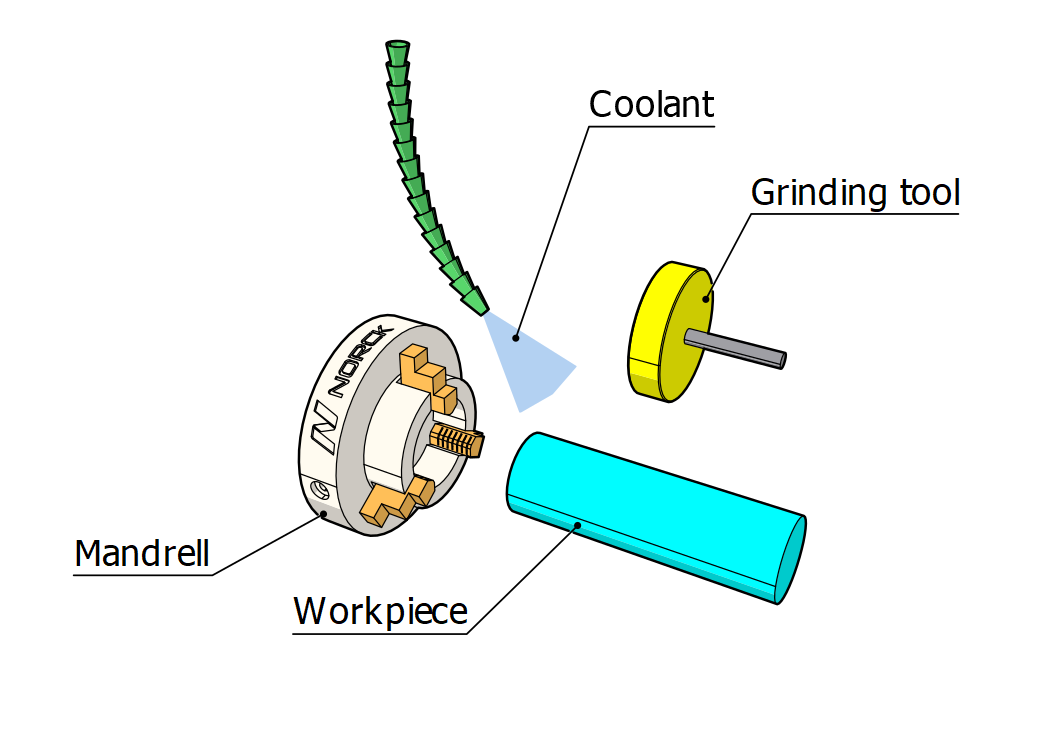

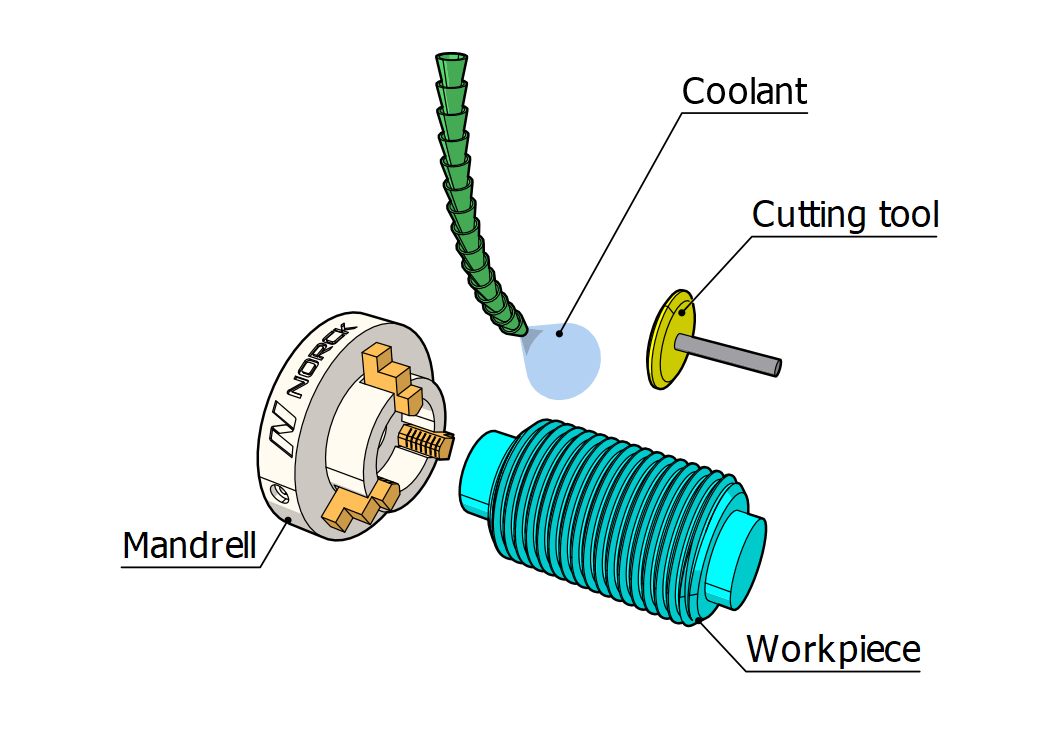

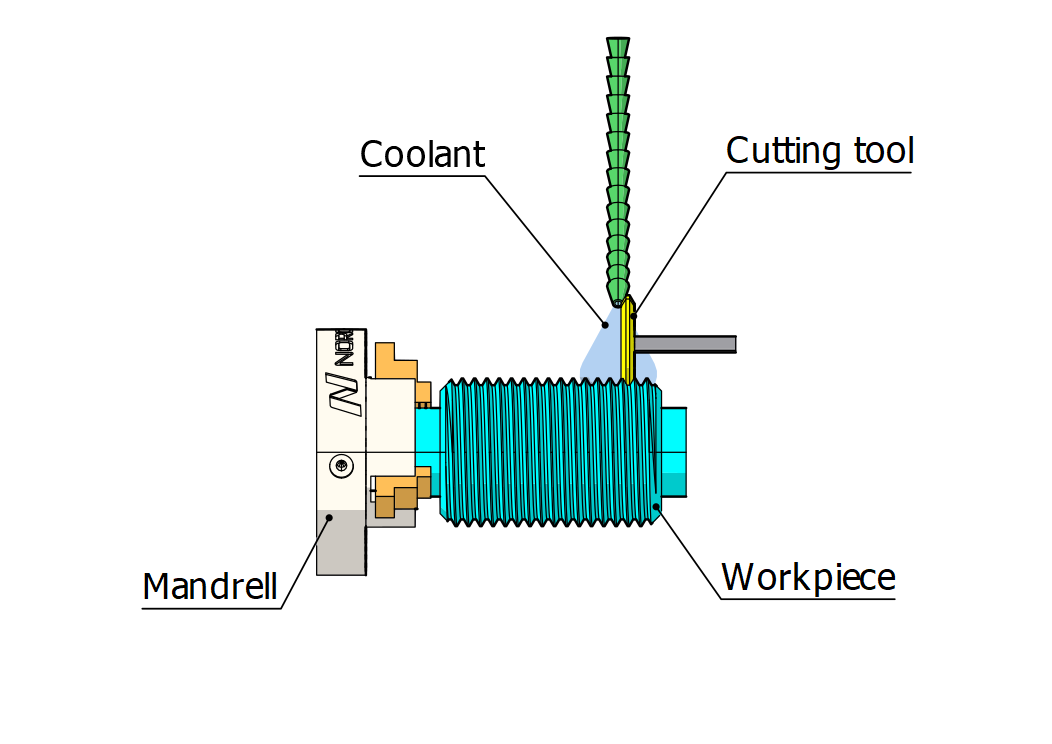

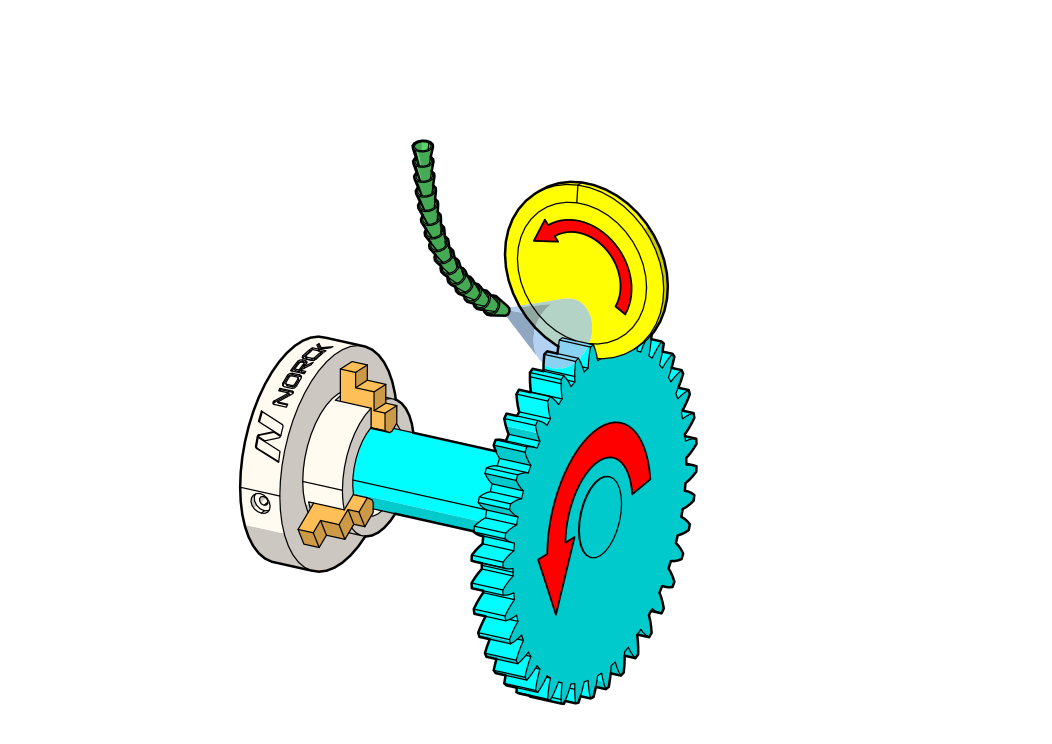

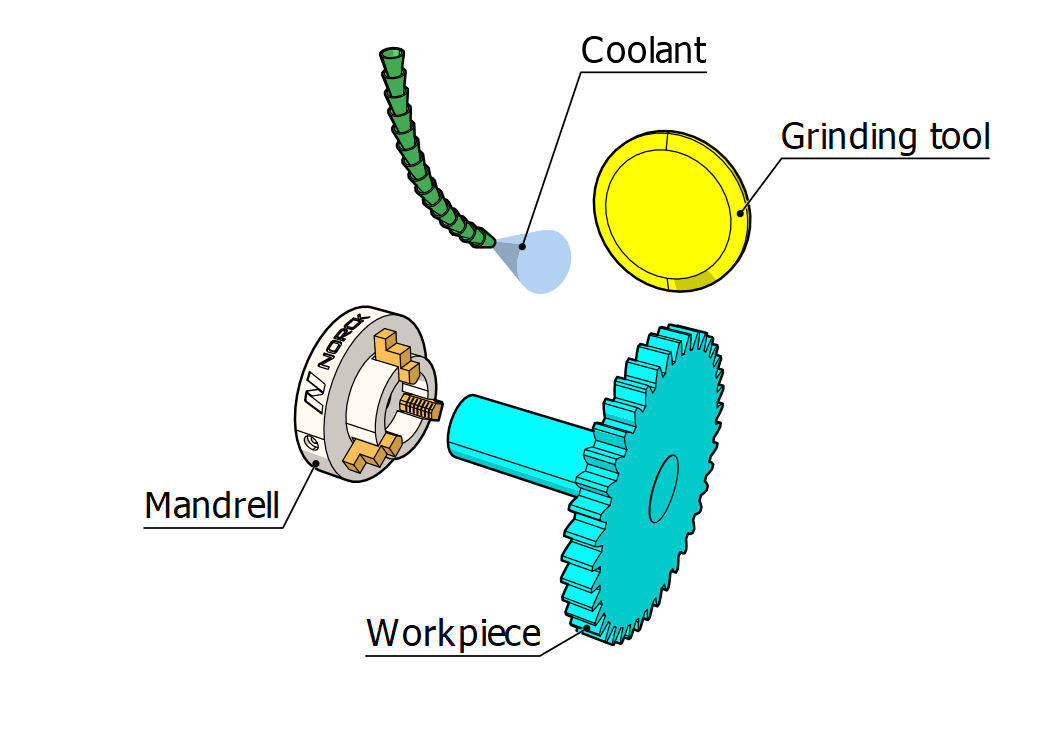

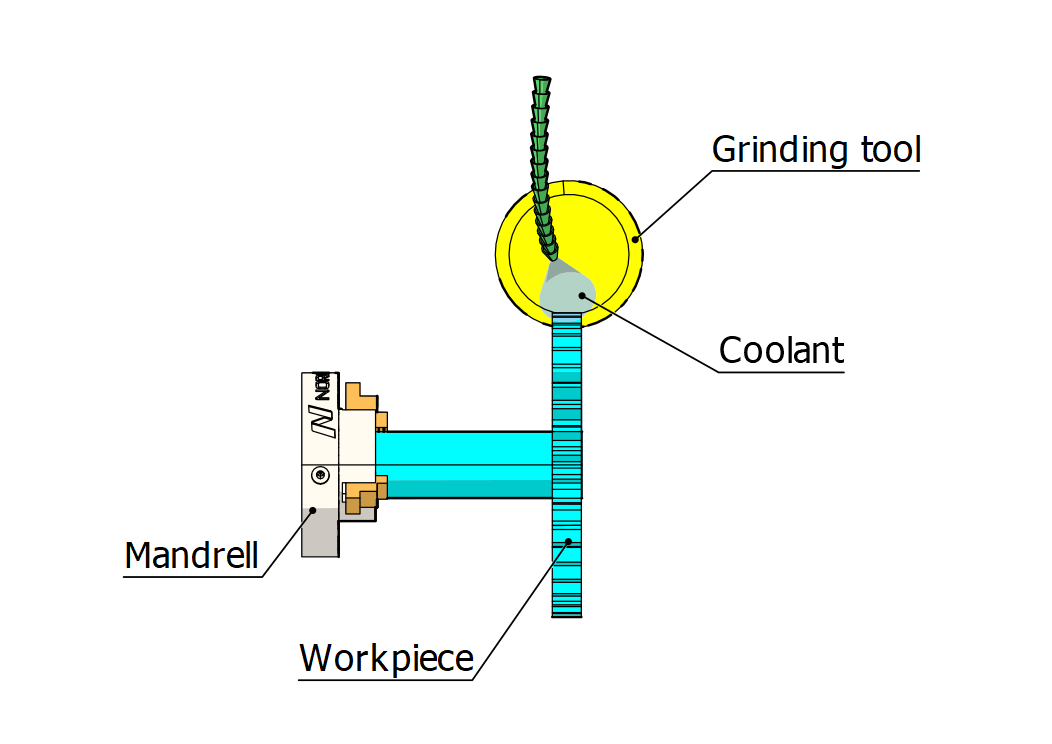

- OD/ID Grinding: Precise roundness for shafts, bearings, etc.

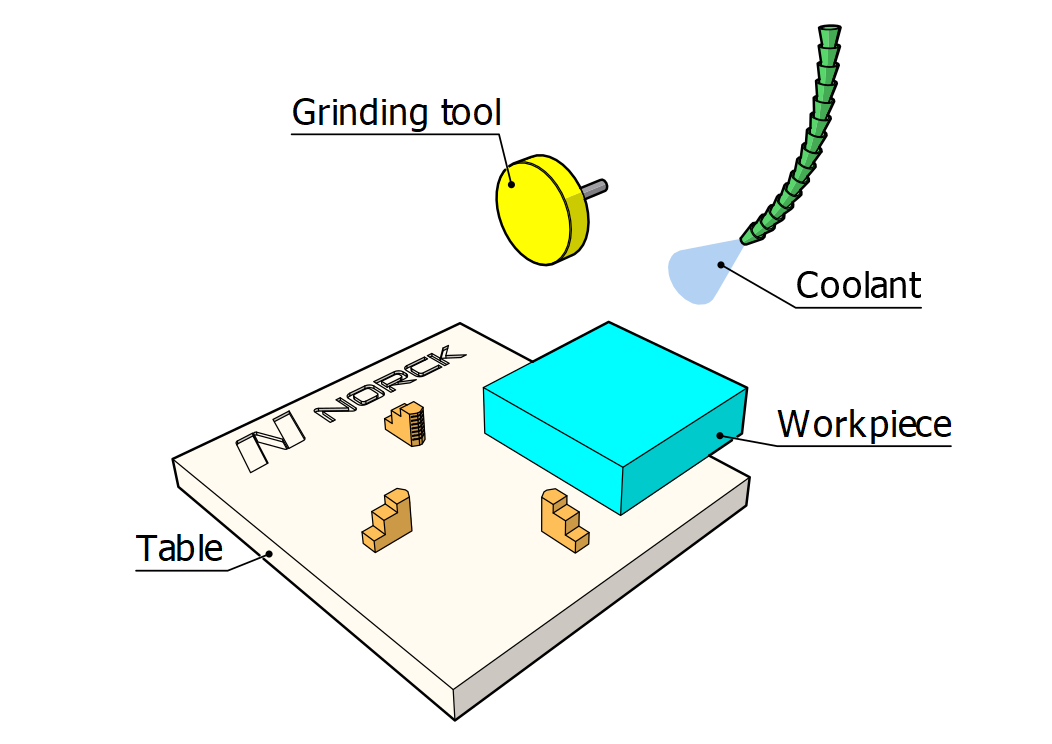

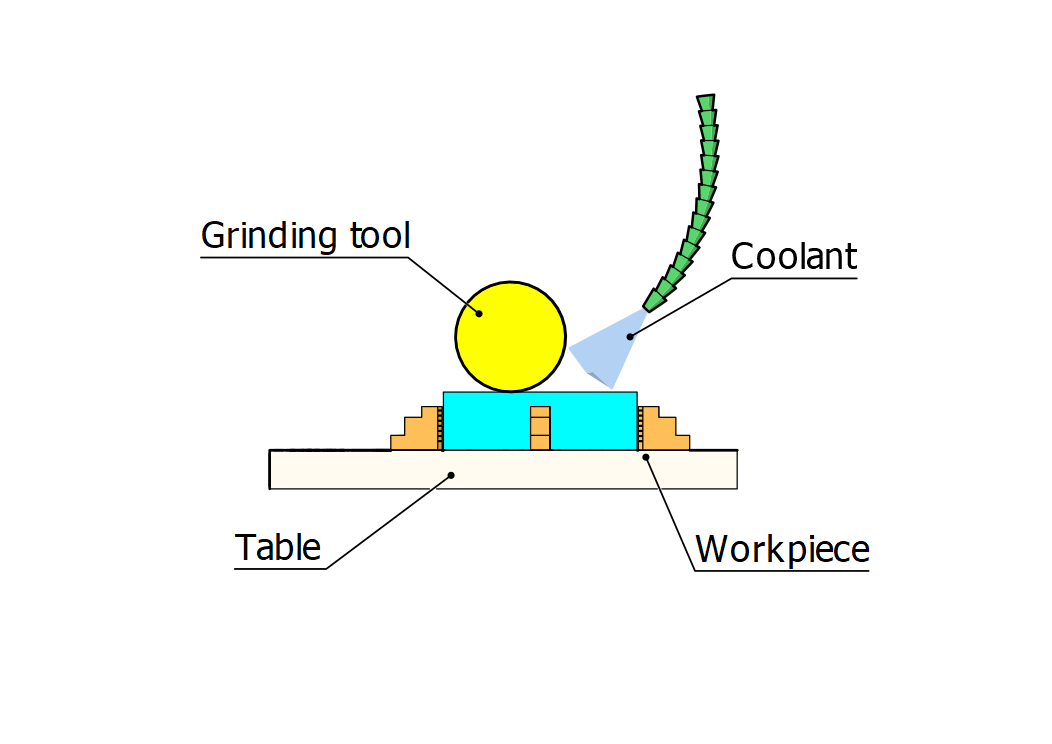

- Surface Grinding: Ultra-smooth finishes (Ra < 0.8 µm).

- Centerless Grinding: High-volume, high-precision results.

- Materials: Steels, hardened alloys, ceramics, composites.

- Inspection: In-process checks and surface measurements.

English

English