Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

The industrial sector comprises of companies that design, develop, manufacture, market, and sell machinery, equipment, supplies, or services for manufacturing and construction companies.

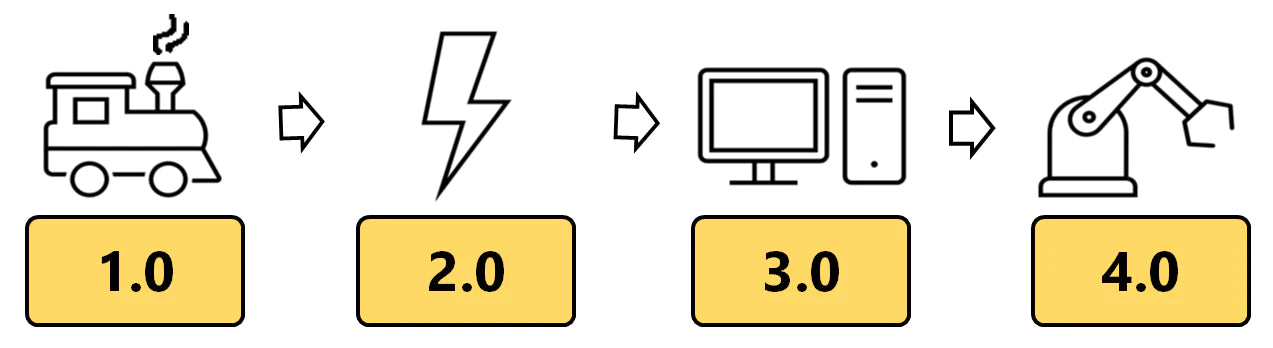

With the discovery of steam power, fabrication machines used steam as an energy source, and industrial fabrication was born. It is often referred to as Industry 1.0.

Around 1840, new technological systems were invented using electricity as a power source, leading to more complex machines known as Industry 2.0.

The third industrial sector revolution started with the computer's invention around 1970, leading to the automation of some manufacturing processes. Industry 3.0 introduced automated systems in assembly lines with automatic and semi-automatic machines that relied on human input.

Nowadays, we are in the era of Industry 4.0, which uses intelligent machines that can trigger action, control each other, and exchange without human interaction.

Norck delivers expert manufacturing and supply chain solutions for the industrial sector, empowering manufacturers, OEMs, and service providers to build, maintain, and optimize their operations. We produce high-performance components, custom assemblies, and replacement parts that meet the rigorous demands of industrial environments.

Norck is certified with the ISO 9001:2015 quality management system, showcasing its dedication to excellence. Key aspects include:

This certification reflects Norck’s ongoing commitment to quality and performance.

Click here to view Norck's ISO certification.

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.