Custom Components Manufacturing Services

Norck: Precision Manufacturing and Engineering for Your Custom Component Needs

Norck takes your vision and transforms it into reality with expert custom component manufacturing services. We specialize in creating unique, application-specific parts across diverse industries, including aerospace, automotive, robotics, medical, electronics, and more.

Norck is certified with the ISO 9001:2015 quality management system, showcasing its dedication to excellence. Key aspects include:

- International Standards: Ensuring all processes align with globally recognized quality benchmarks.

- Customer-Centric Approach: Prioritizing customer satisfaction through consistent and reliable service.

- Continuous Improvement: Emphasizing the optimization of operations and workflows.

- Operational Excellence: Maintaining efficiency and reliability in all activities.

This certification reflects Norck’s ongoing commitment to quality and performance.

Click here to view Norck's ISO certification.

What is custom component manufacturing?

Custom component manufacturing designates a set of fabrication methods used to manufacture a custom part in small quantities. Custom manufacturing is used in the following sectors:

- Medical: medical devices, surgical tools, implants, orthosis, and prosthesis

- Industrial: Special machines, welded structures, gears, shafts, jigs and fixtures, and enclosures.

- Hardware: Hinges, handles, tools, screws, nuts, rivets, plastic bearings

- Aerospace and automotive: Bodies of aircraft and cars, electrical cables, prototypes, interior command units

- Consumer Products: Home appliances, cooking utensils, PC enclosures, jewelry, and products' bodies.

What are the advantages of custom component manufacturing?

Custom component manufacturing offers many advantages over medium and high-volume production:

- Tailored Components: Get parts and assemblies built to your exact specifications, no need to compromise.

- Startup & Small Business Friendly: Easily transform ideas into prototypes and test the market affordably before large-scale production.

- Cost-Effective for Small Runs: Lower upfront costs for development, tooling, and fabrication, plus the flexibility of smaller order quantities.

- Maximum Customization: Design products exactly as envisioned.

How is it fabricated?

Norck offers an extensive choice of materials for custom component manufacturing:

1. Custom metal component:

A. Additive Manufacturing

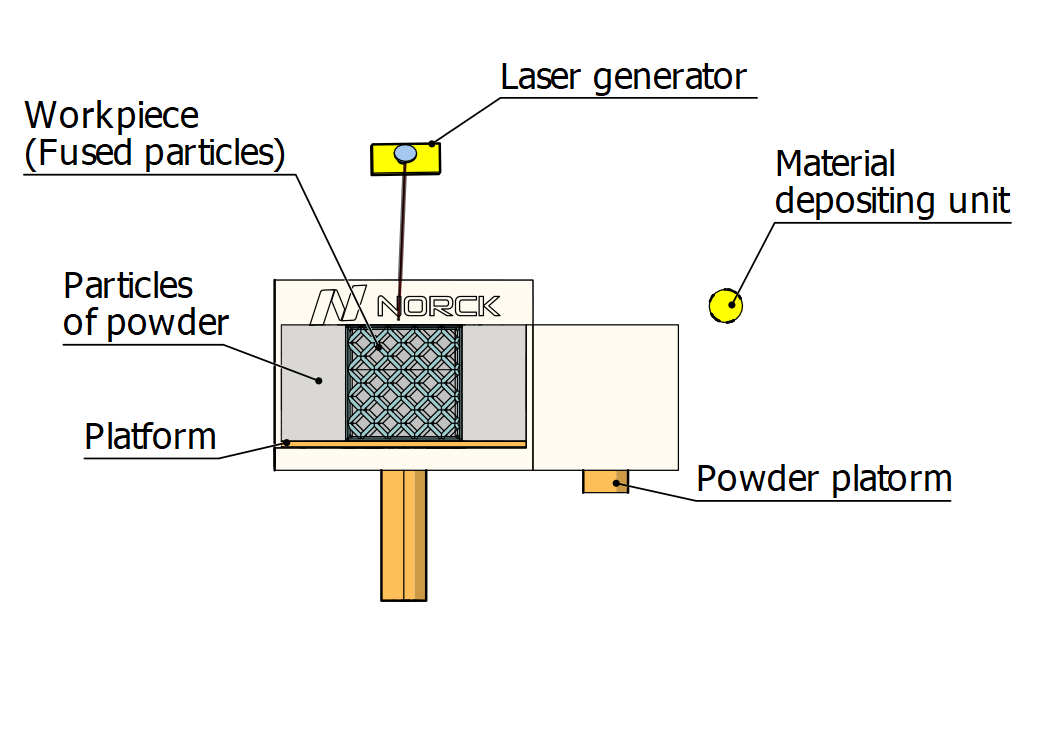

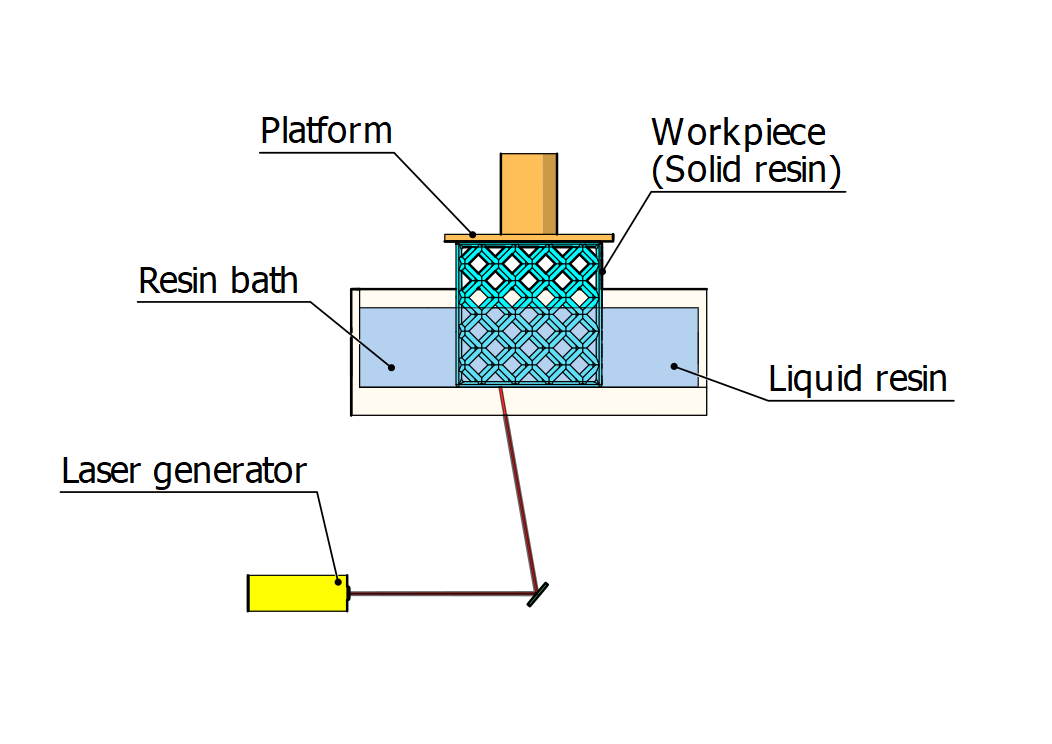

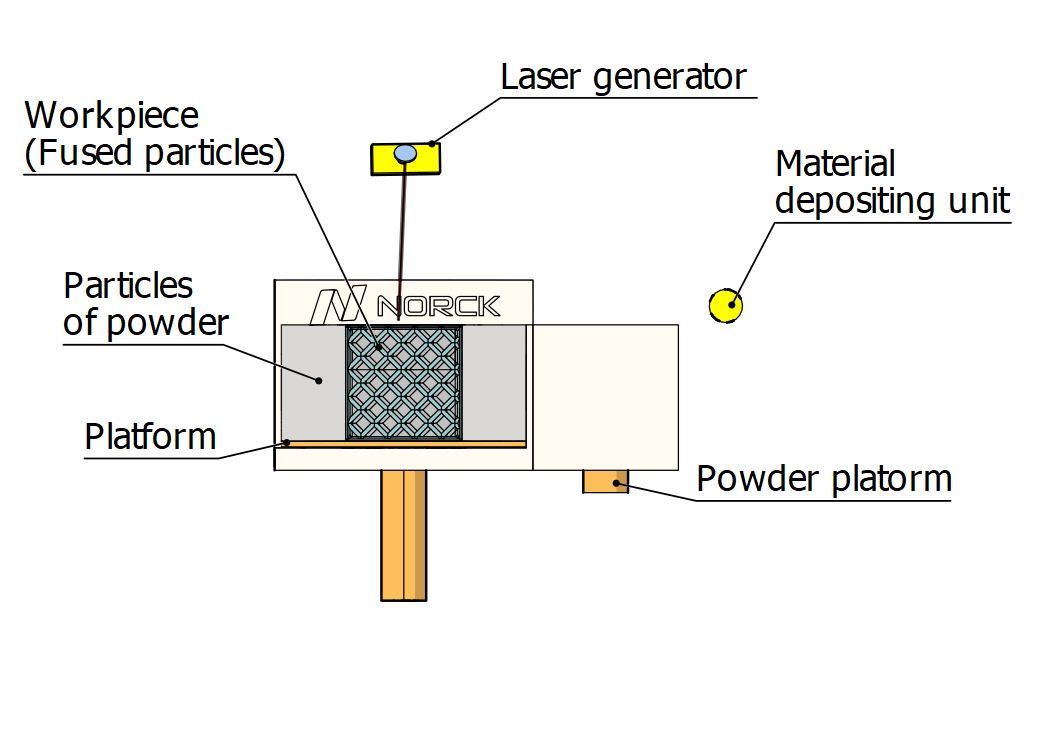

• Metal 3D Printing(DMLS): It is a process used to produce custom parts by fusing metal powder particles using a laser beam. It uses different metal materials such as:

- Titanium

- Stainless steel

- Aluminum

- Nickel

- Cobalt

- CopperPlatinum

- Gold

- Silver

Metal 3D Printing (DMLS)

B. Subtractive manufacturing

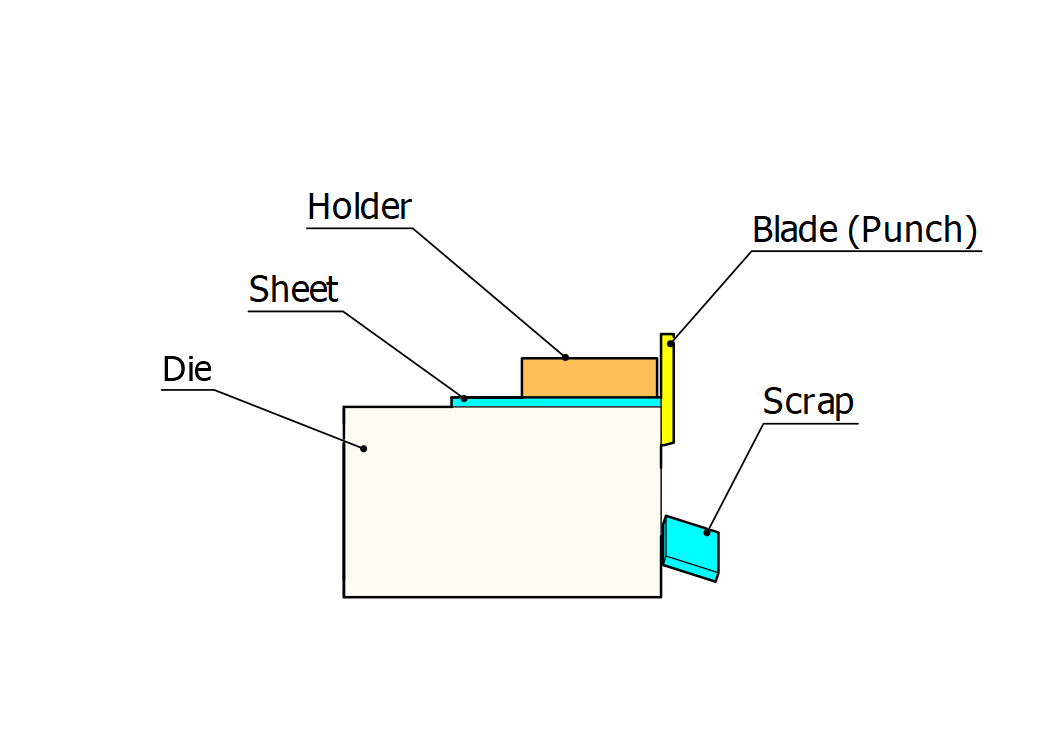

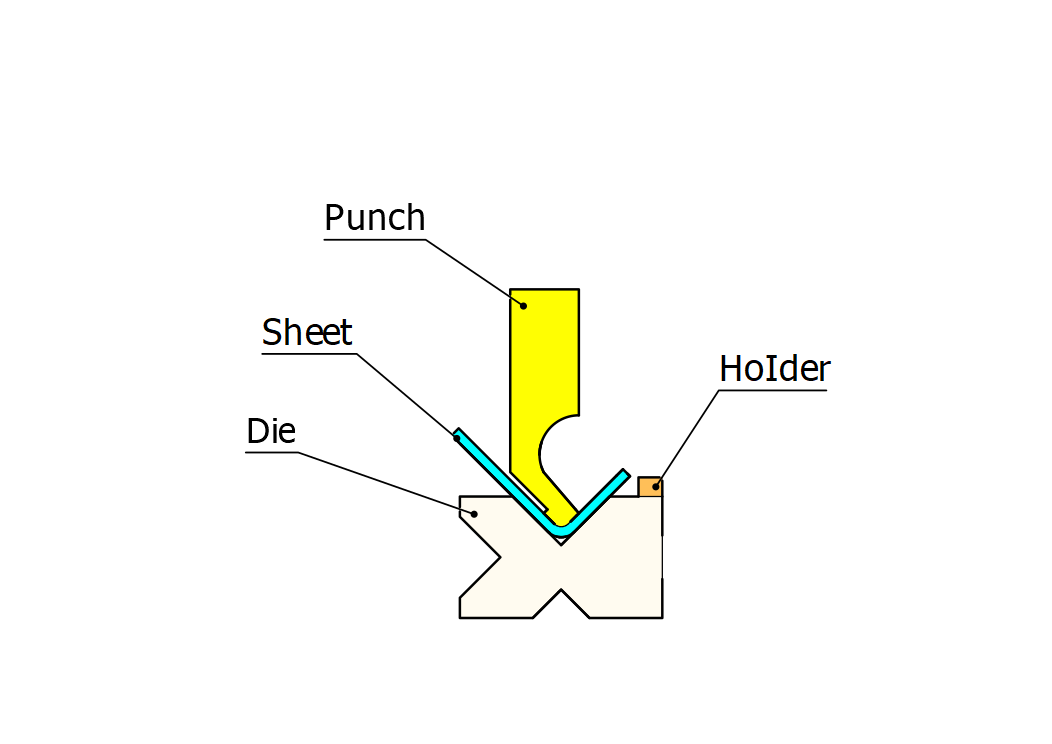

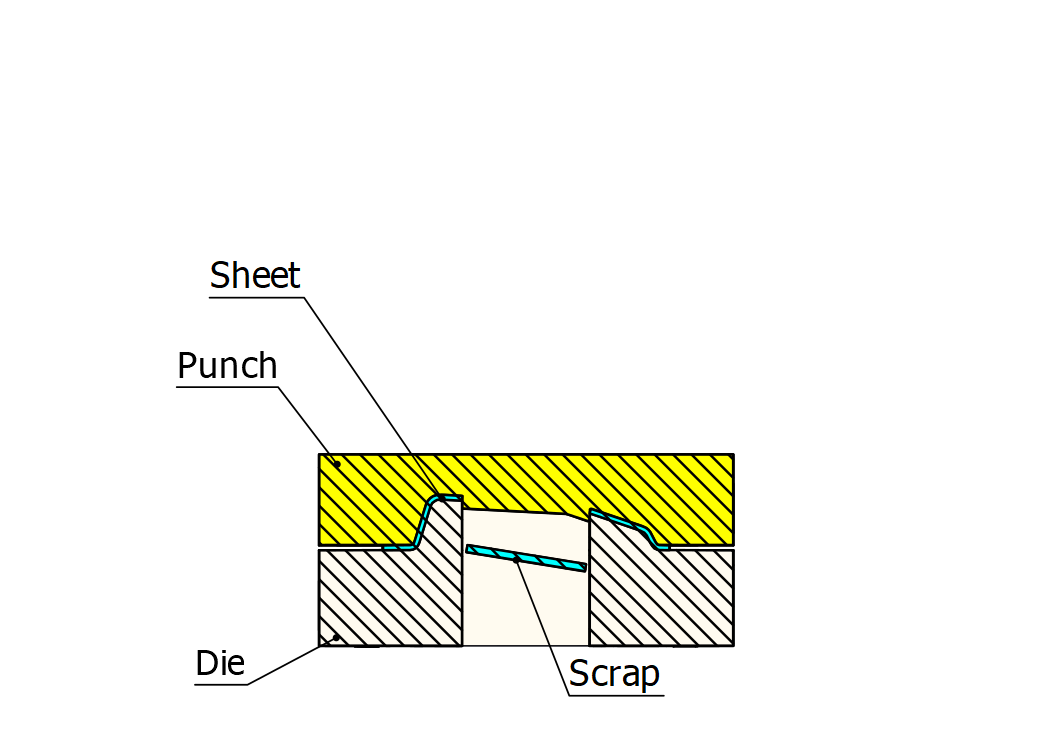

• Sheet metal fabrication: It is a set of manufacturing methods of cutting and forming metal sheets to produce parts. The mainly used materials are:

- Steel alloy

- Stainless steel

- Aluminium

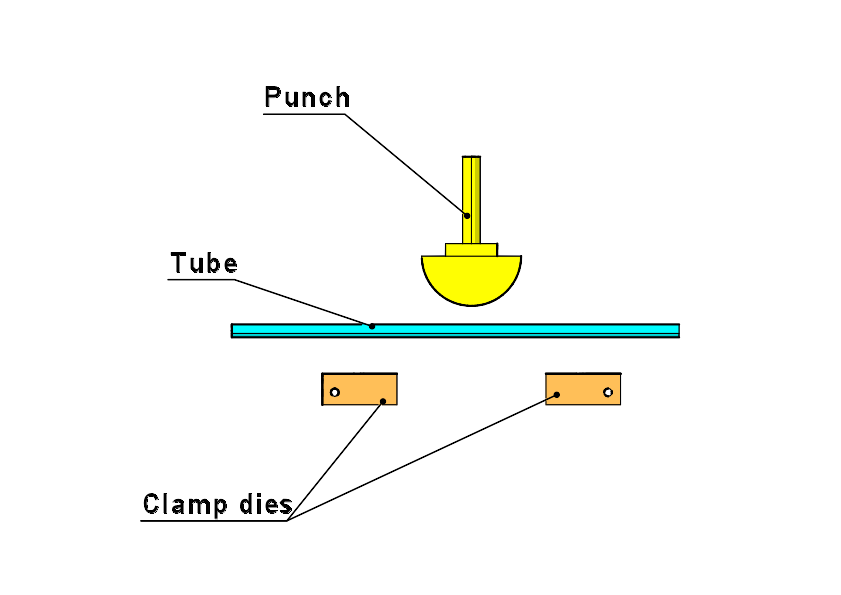

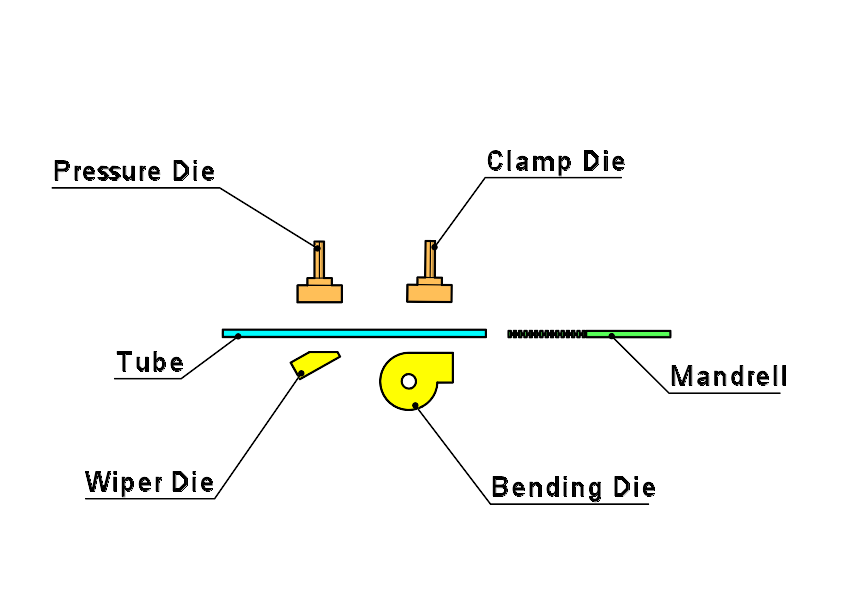

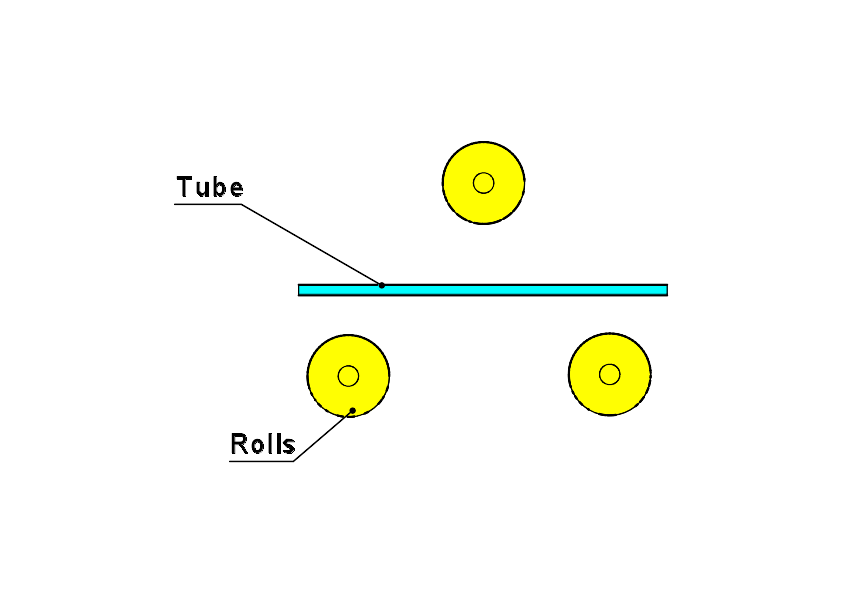

• Tube bending: Tube bending is a set of techniques to bend straight tubes into different shapes. The process can be performed by using cold or hot methods. Generally, the round stock is used, but rectangular tubes and pipes can also be bent.

A post-process can be mandatory to remove burrs. It can also be used with laser tube cutting to add holes and shapes or to cut the edges

• CNC machining: CNC machining (Computer Numerical Controlled machining) designates a process that uses a computer to control the trajectory of the machining tool. It employs many machining techniques, such as milling, turning, and drilling.

• Used materials are:

- Titanium

- Stainless steel

- Aluminum

- Nickel

- Cobalt

- Copper

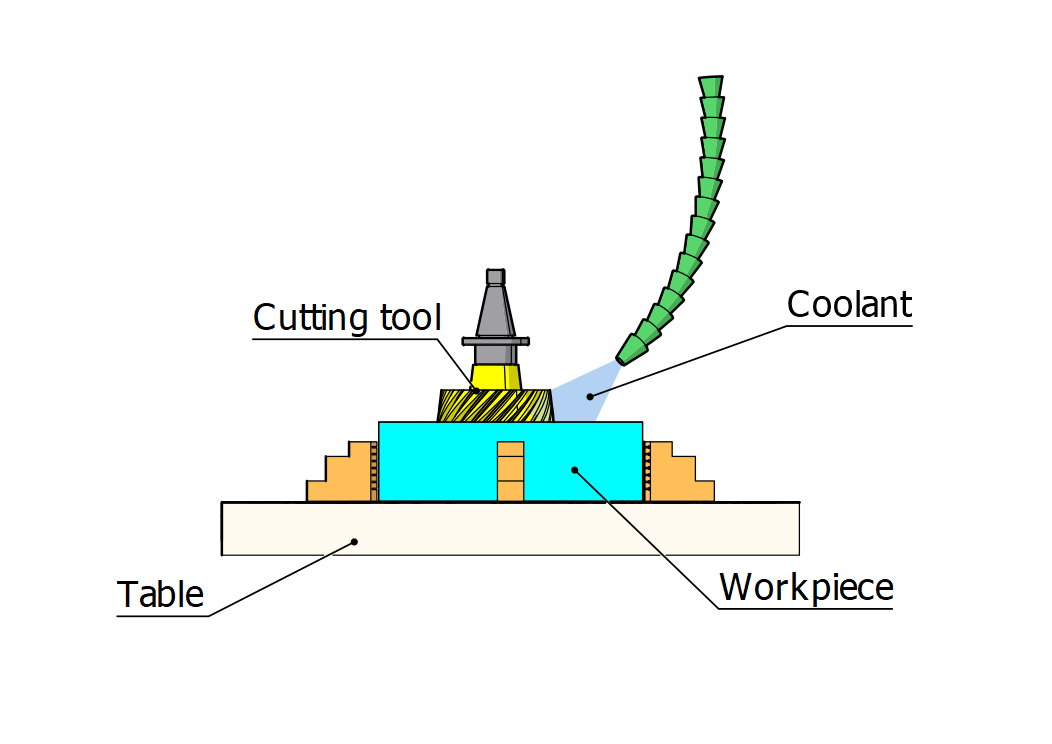

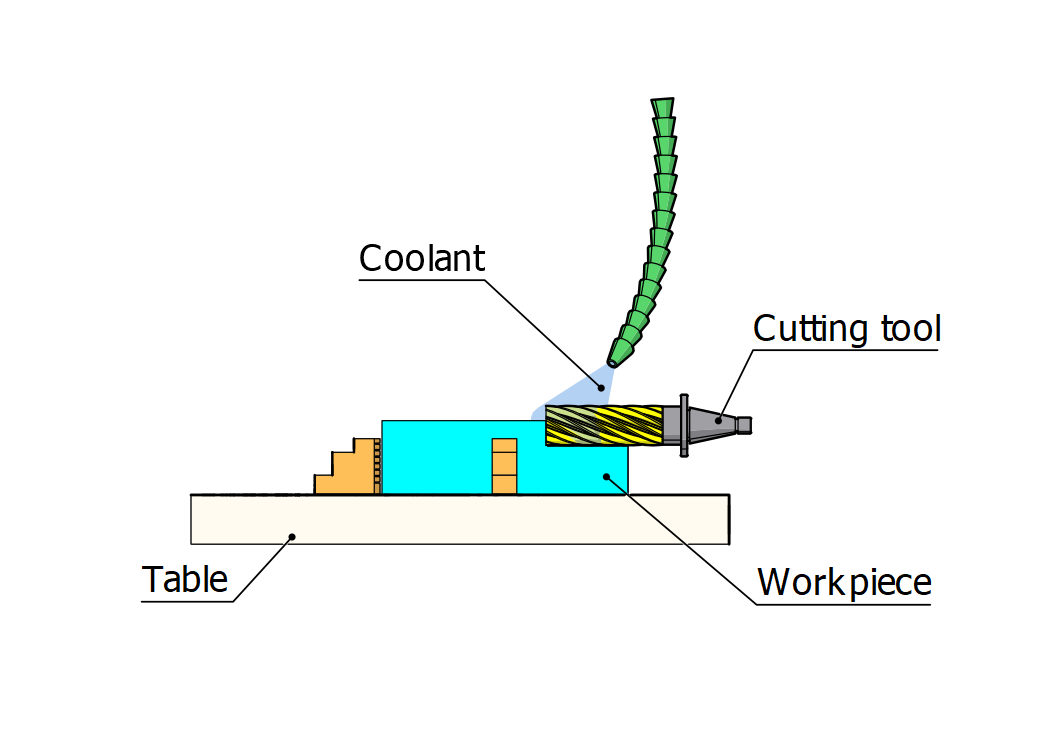

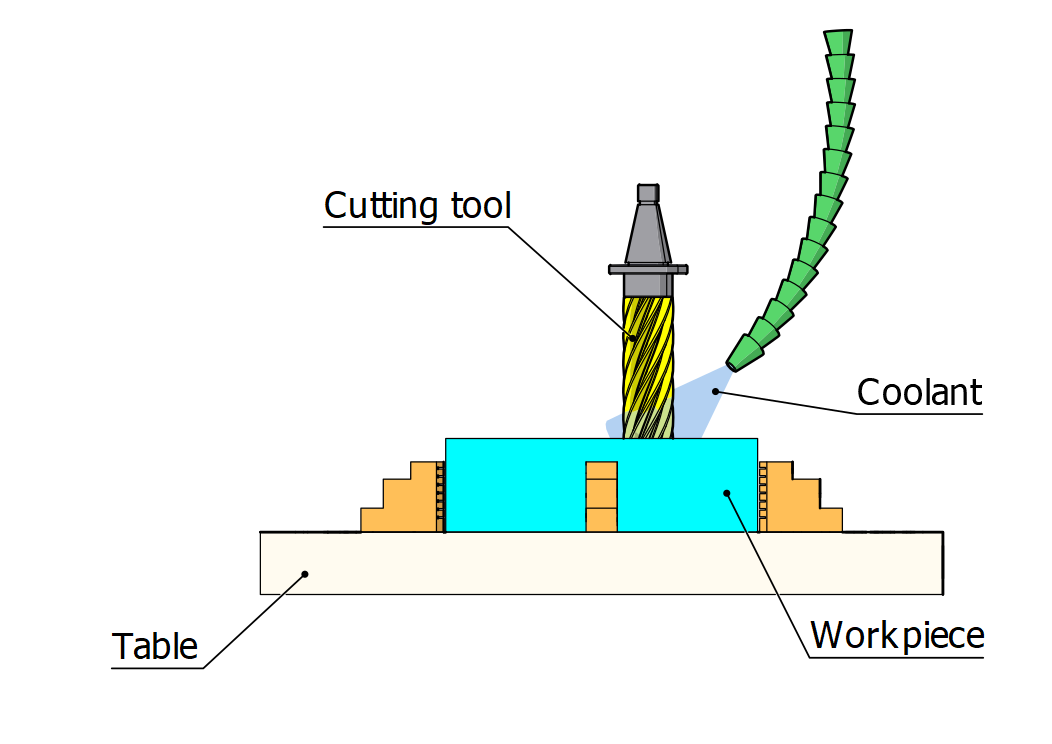

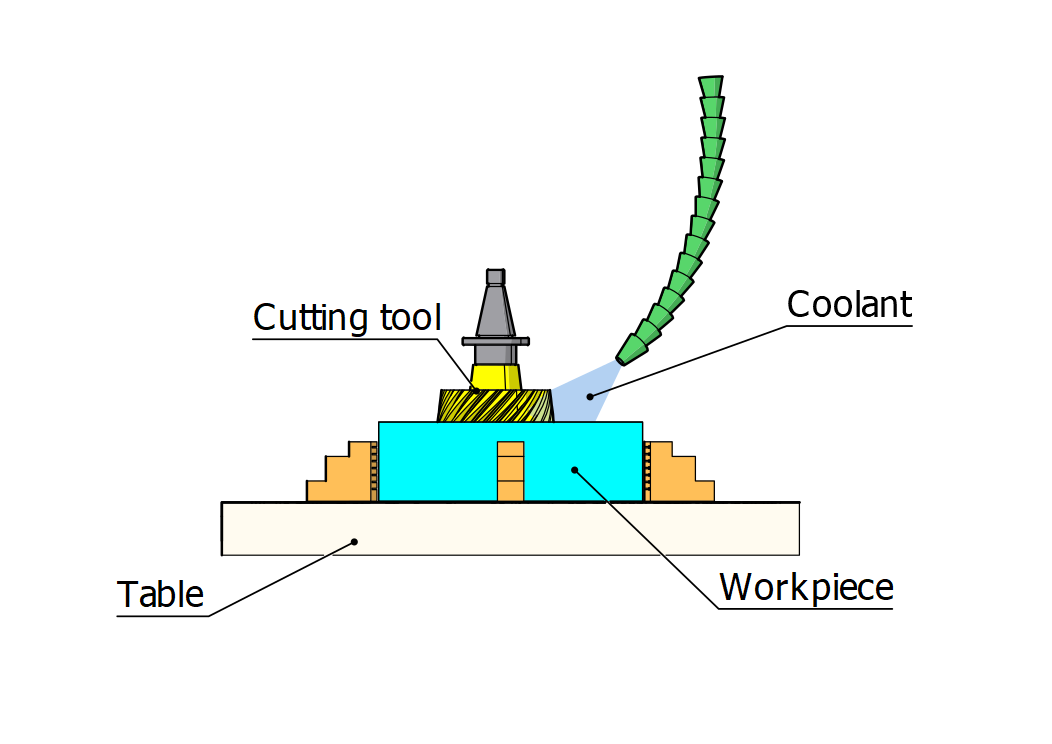

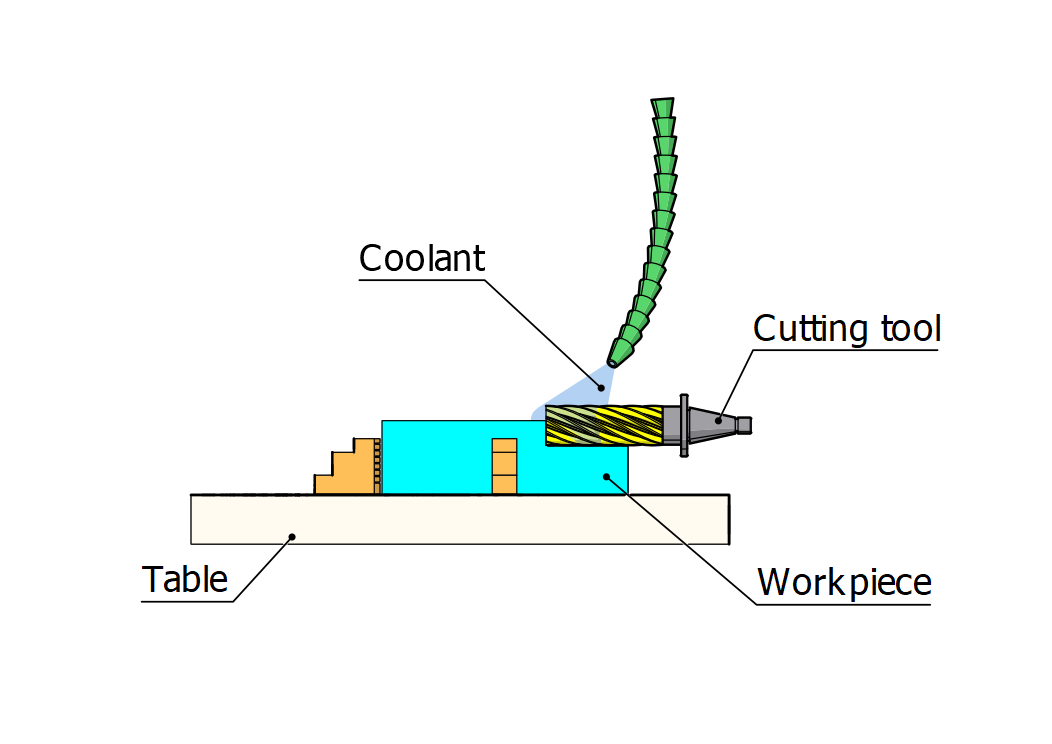

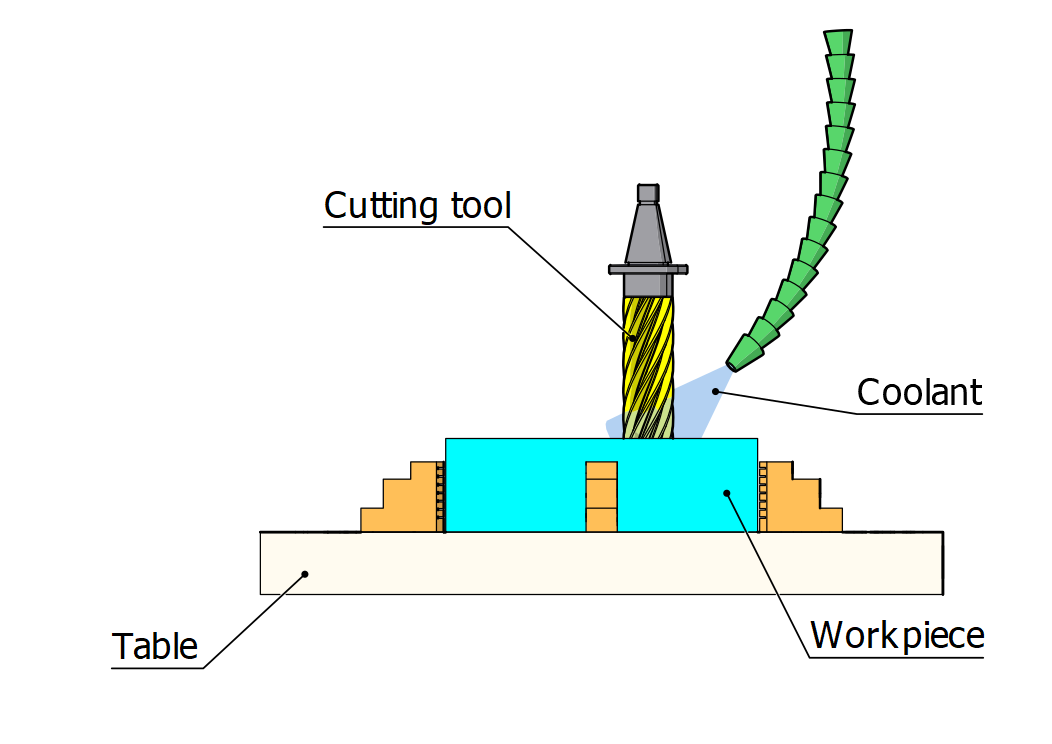

• Milling: It is a process that uses a rotating tool to remove material from the fixed workpiece. There are two types of milling, horizontal and vertical milling.

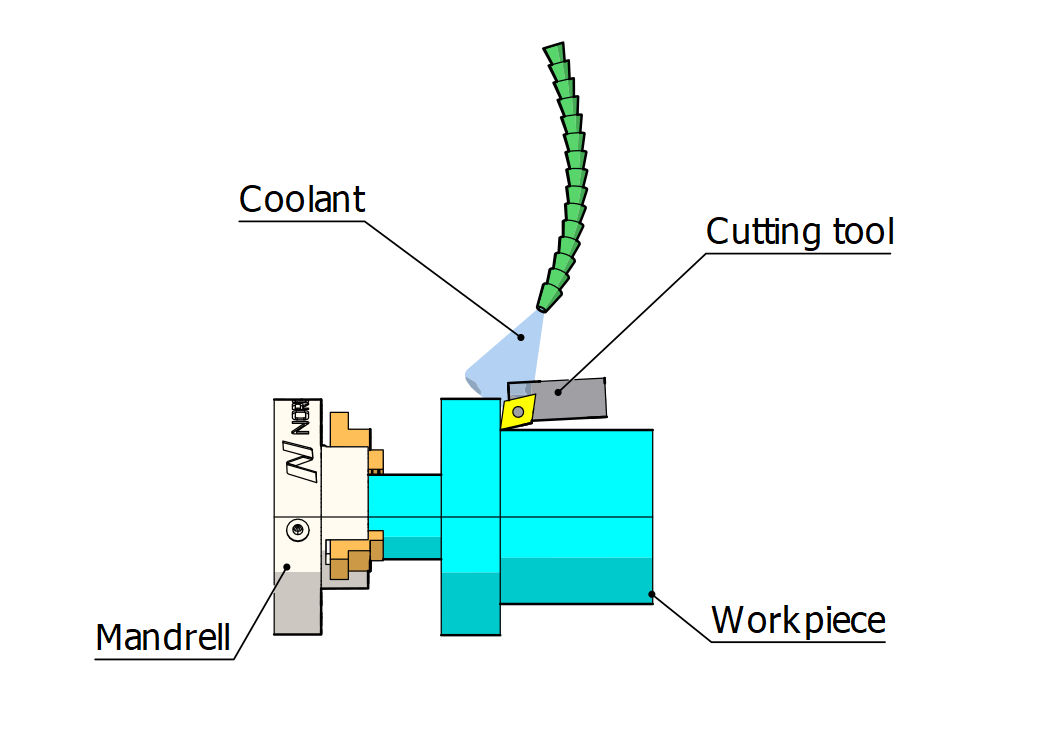

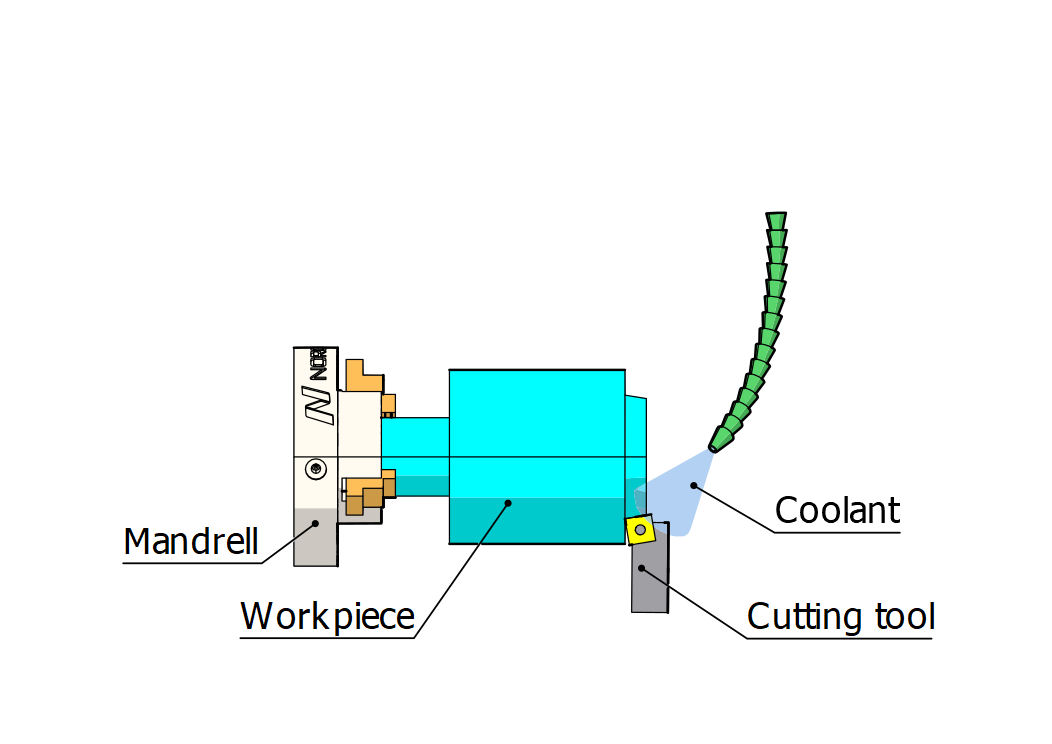

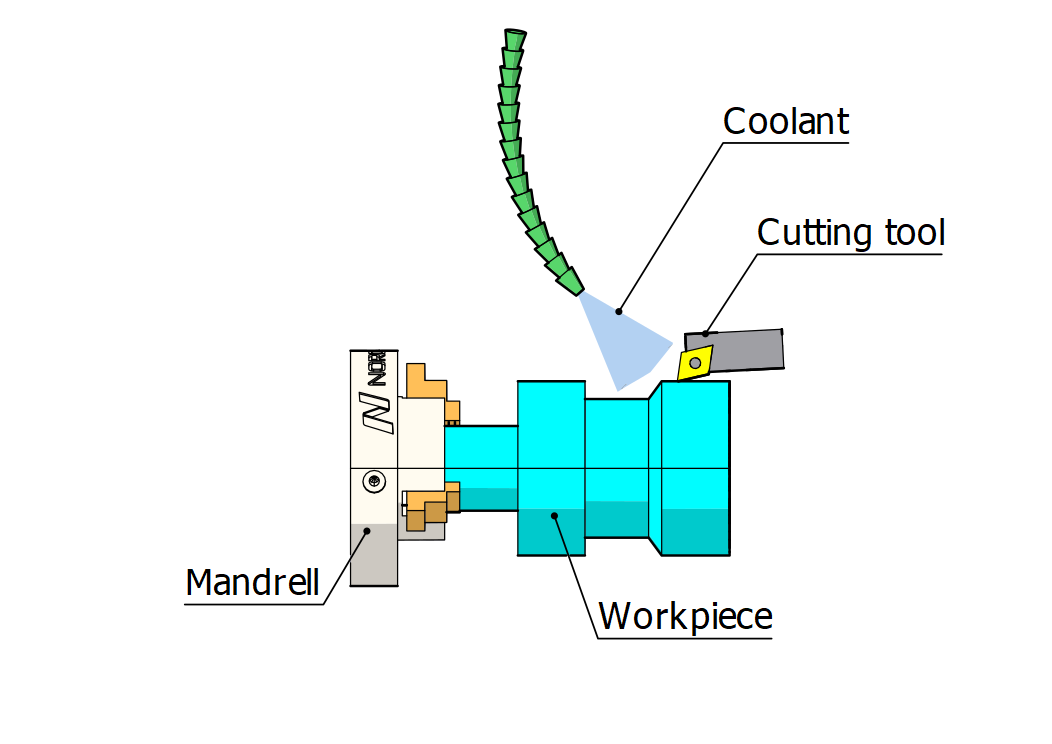

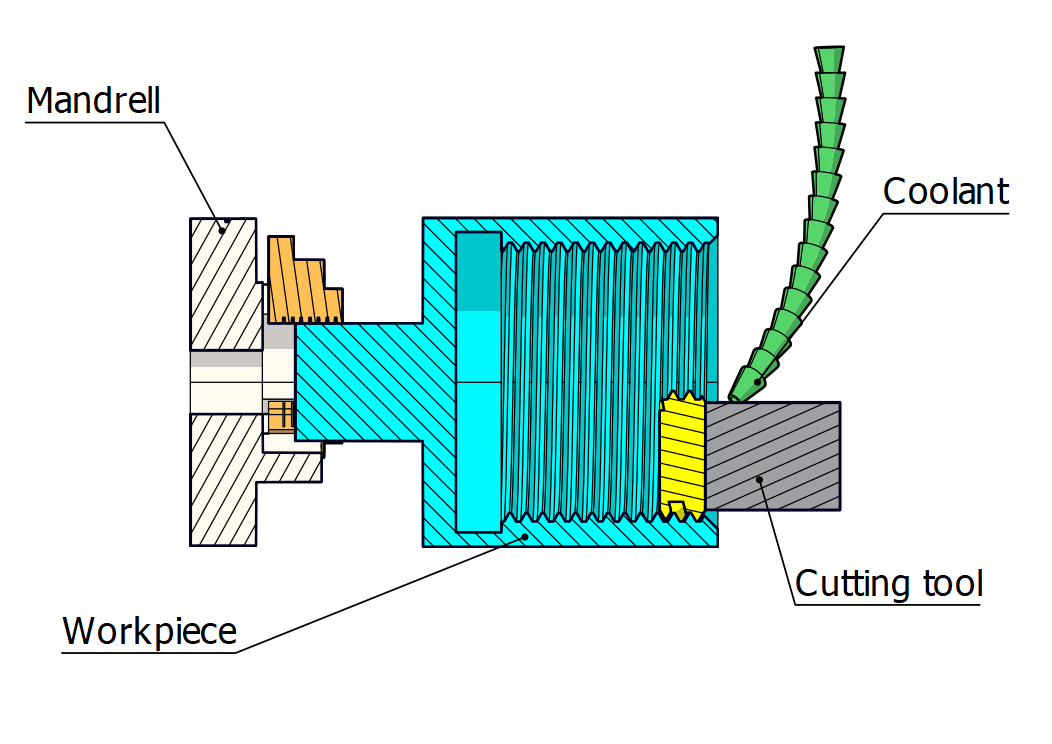

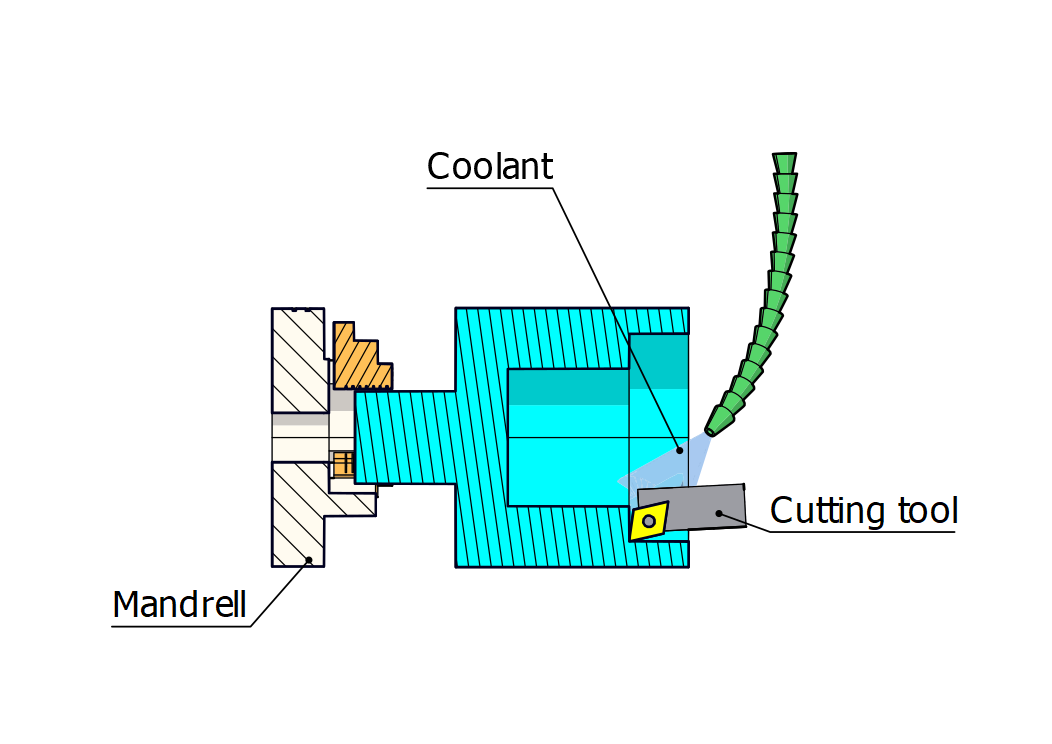

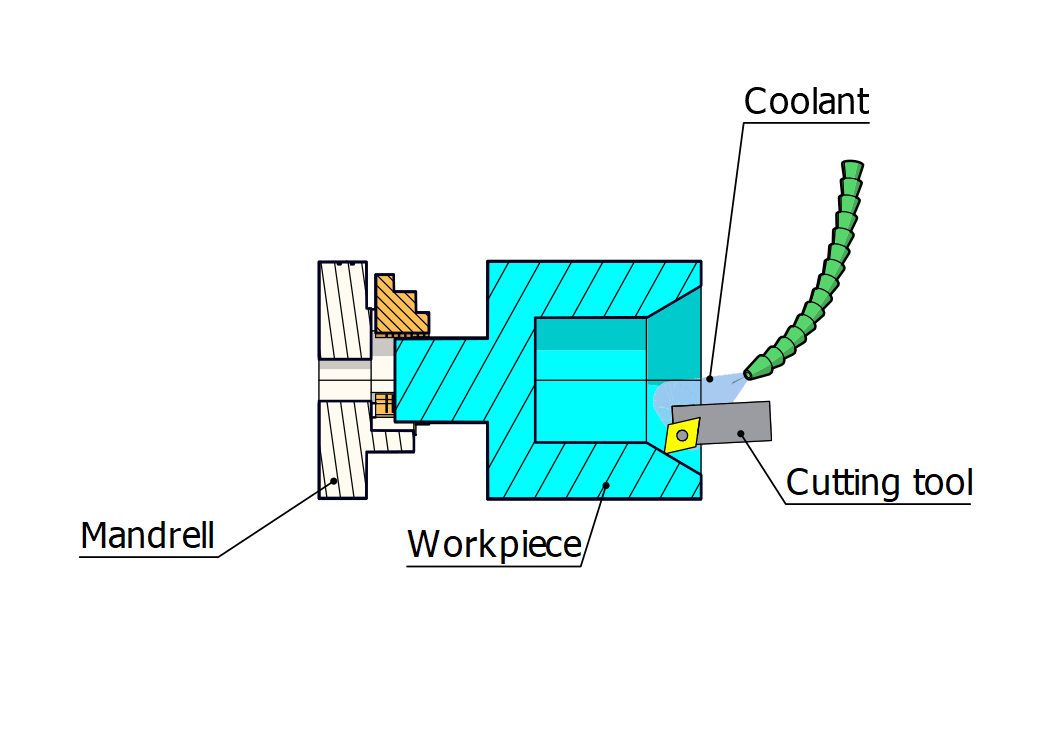

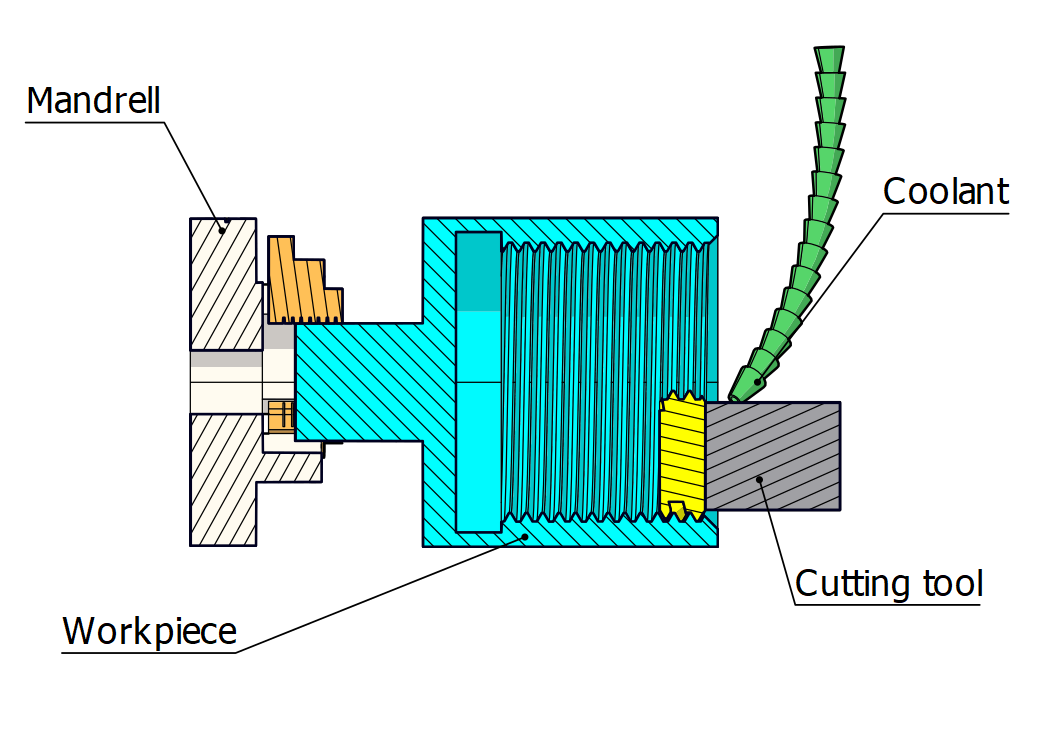

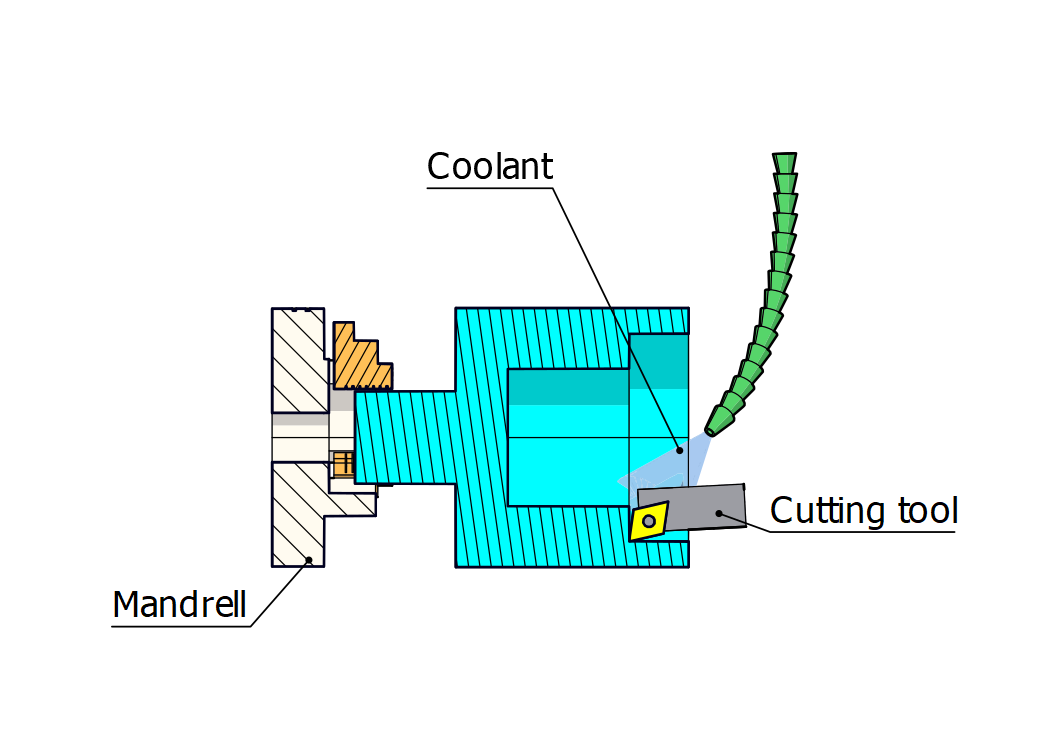

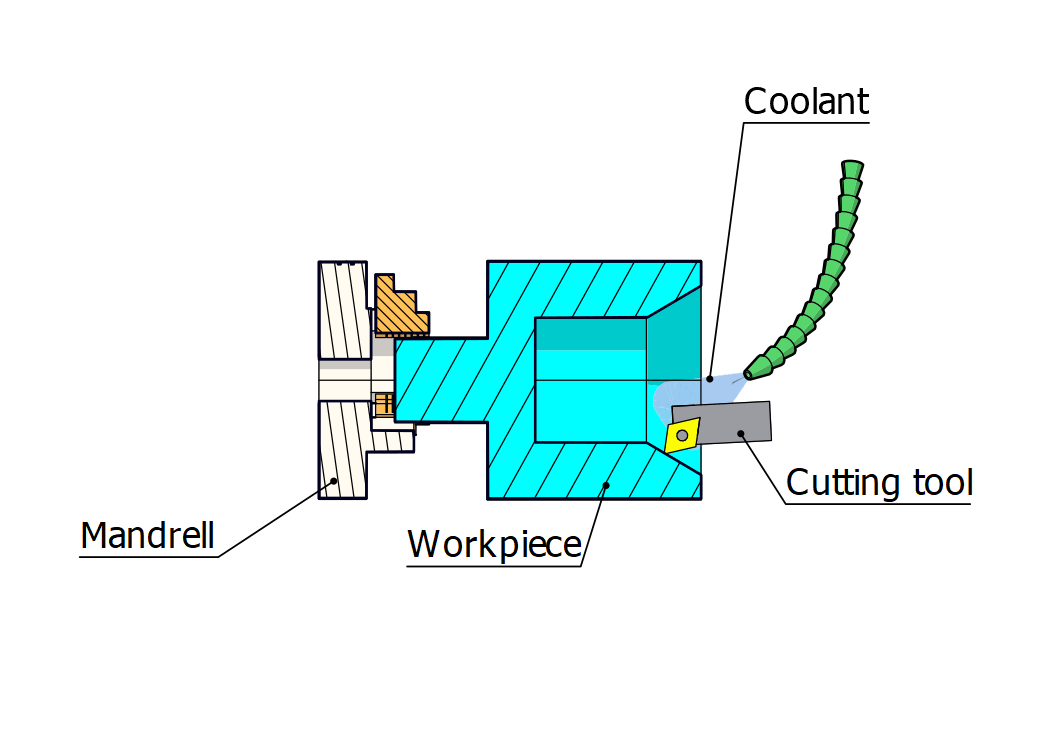

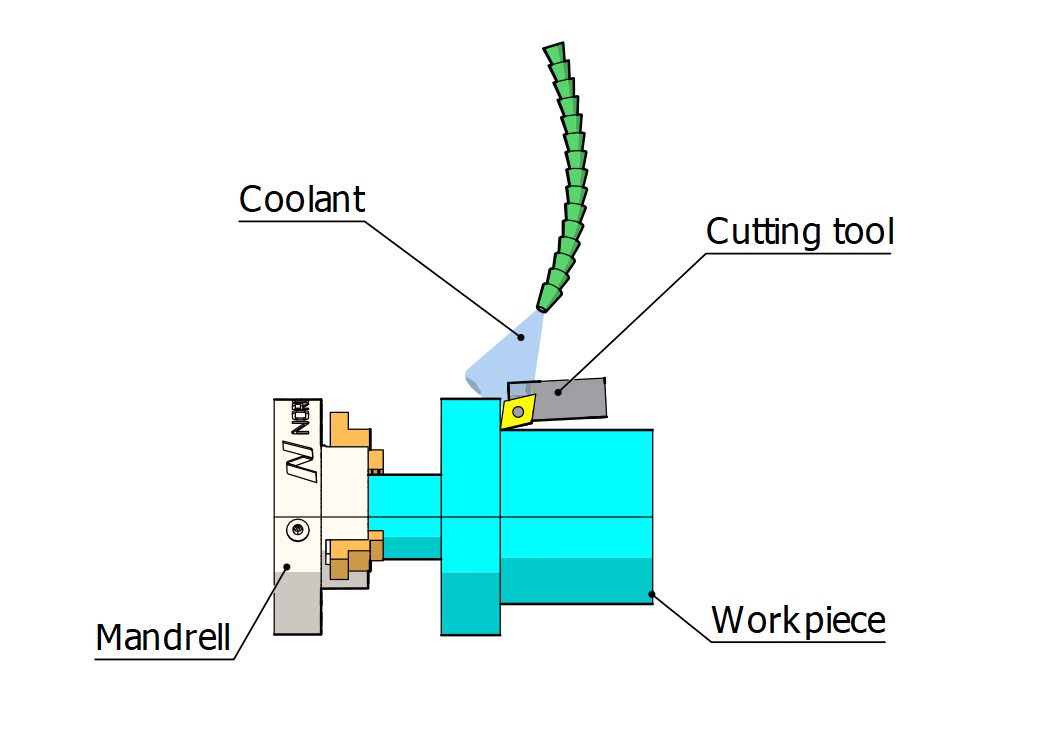

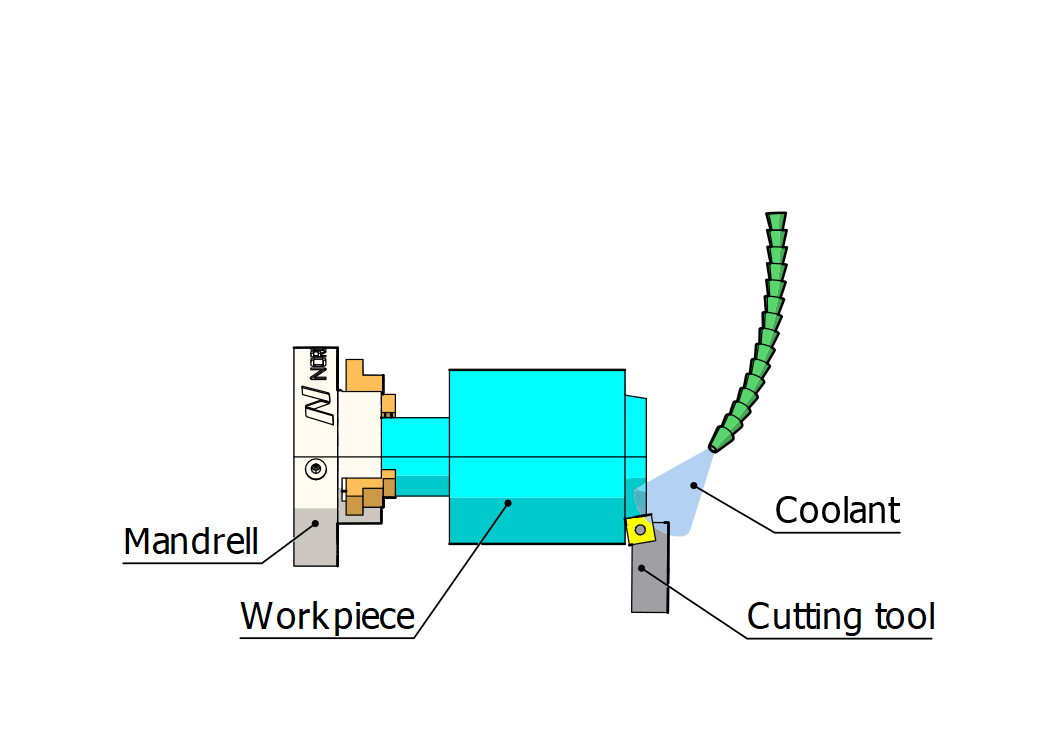

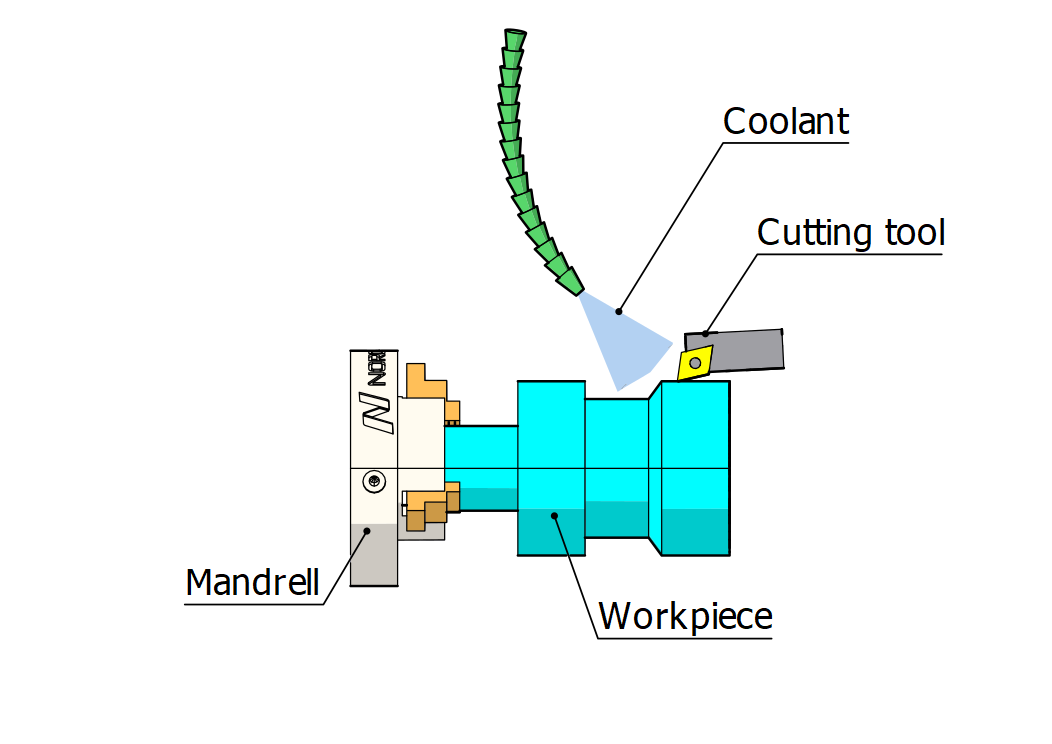

• Turning:This method uses a lathe to turn workpieces at high speeds and a tool with a special shape to remove layers of material from the workpiece. The workpiece shape is generally revolutionary. If the workpiece is long enough, an extra part is used to support the weight of the workpiece.

• Drilling: It is a process used to make homes in the workpiece. The holes are generally perpendicular to the surface but can have angles with special tooling. This process includes taping, counterboring, and countersinking.

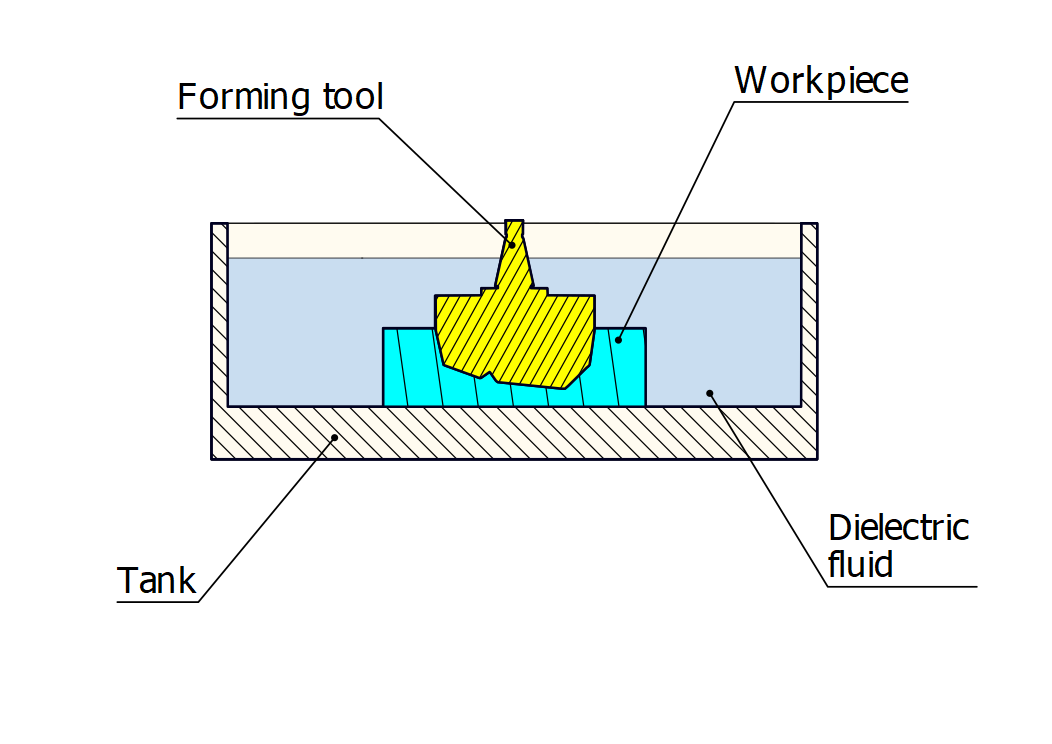

• EDM: It is a thermal cutting process of metal parts using a high voltage electrical discharge, hence the name EDM (Electrical discharge machining). In this technique, electrical discharges (sparks) heat a metallic shape that engraves through the workpiece. EDM can use a wire instead of a shape to cut through the workpiece (wire EDM).

- Titanium

- Stainless steel

- Aluminum

EDM

C. Formative manufacturing:

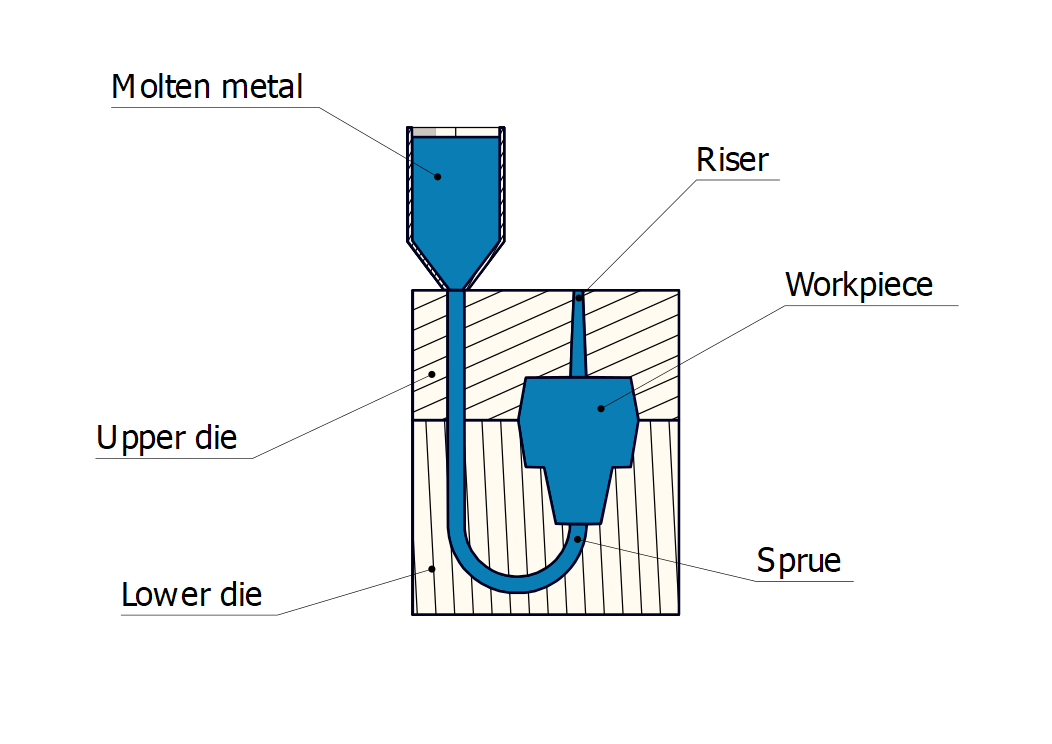

• Die casting: It is a process in which molten metal is fed into a mold cavity under high pressure. Mold is made from hardened steel and contains the shape of the component to be molded. The die-casting process is used for high and medium-volume production due to the high cost of mold fabrication.

Die casting

We offer the following finishes for custom-manufactured metal parts:

- Surface finish

- Deburring

- Plating

- Anodizing

- Heat treatment

- Powder coating

- Painting

- Welding

- Riveting

- Assembly

- Testing

GET A QUOTE

2. Custom plastic part

A. Additive manufacturing

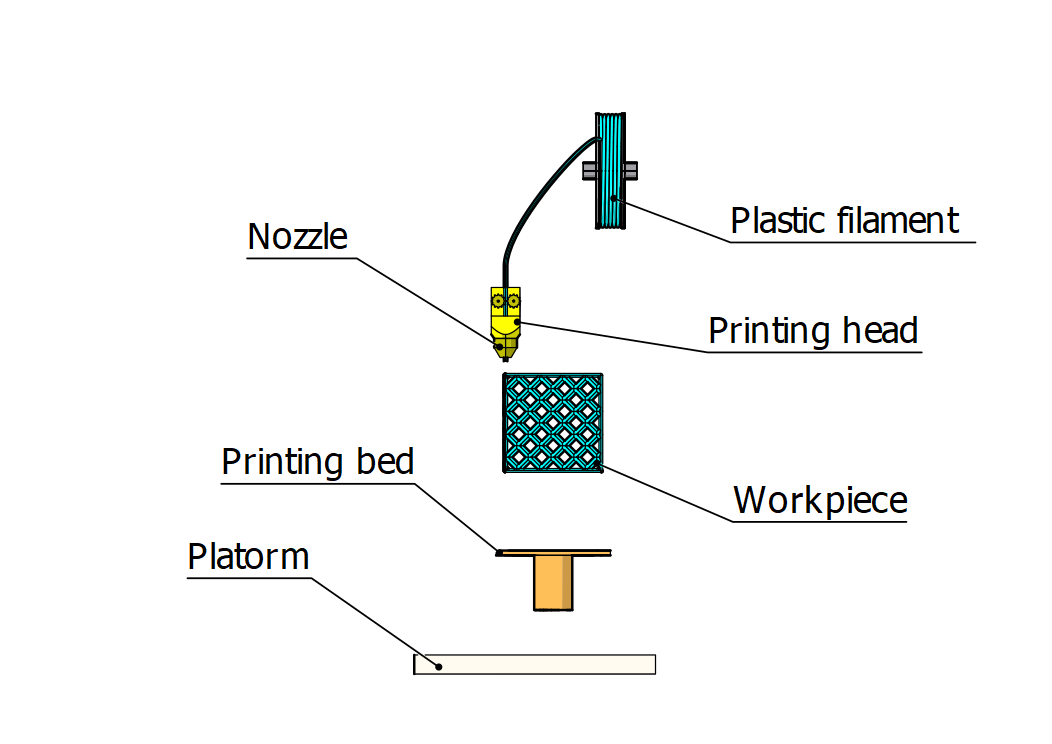

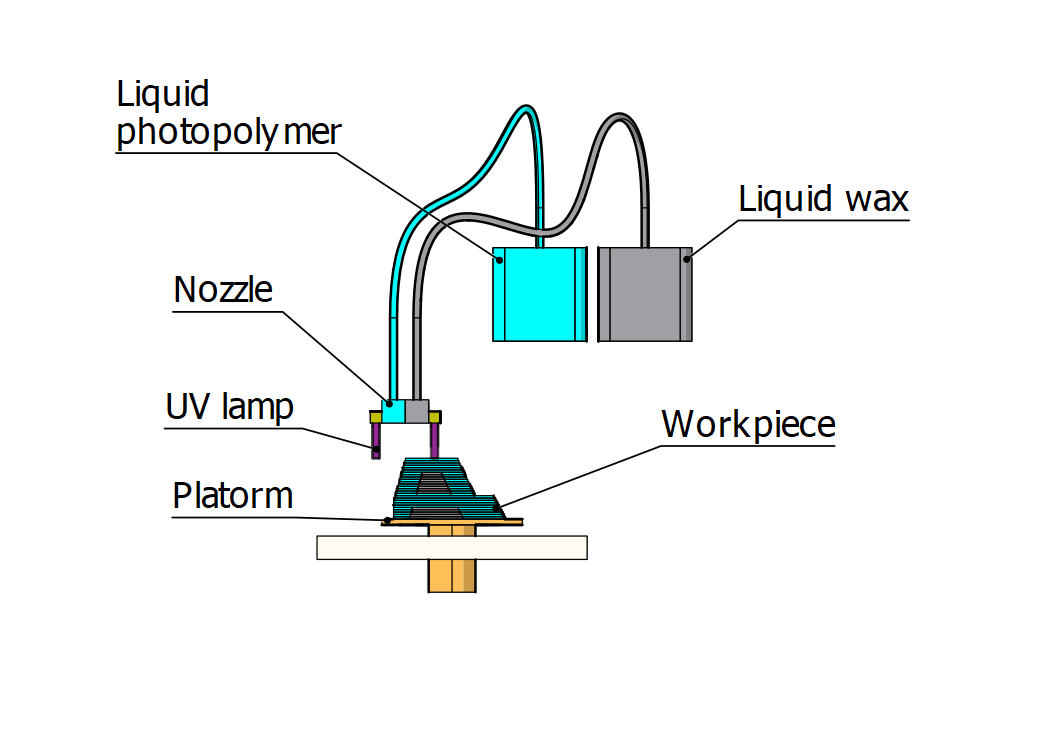

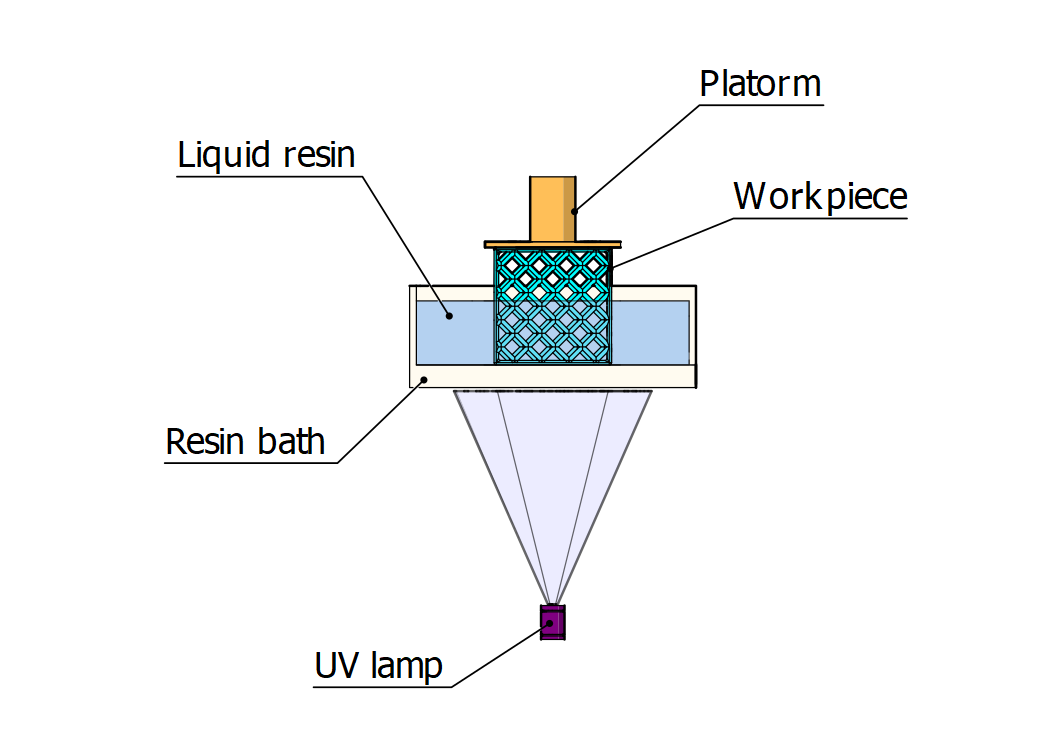

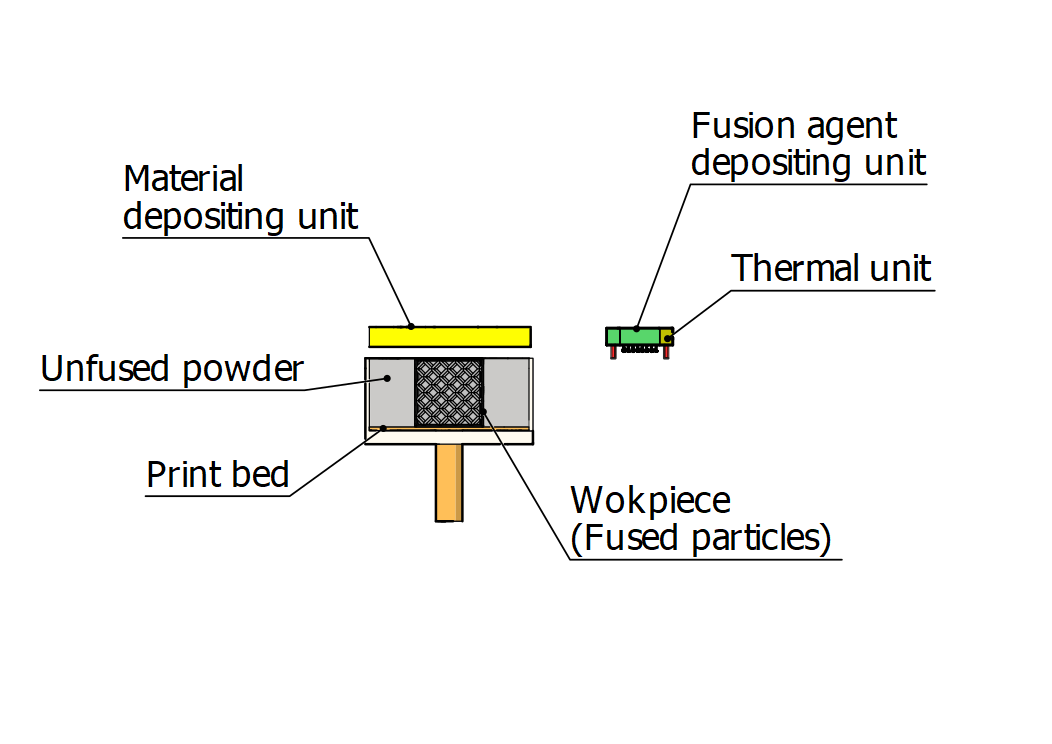

• Plastic 3D Printing: It is a process used to produce custom parts by printing layers of plastic materials. Plastic 3D Printing uses multiple methods to create custom plastic parts, and it is evolving. At Norck, we offer numerous 3D printing methods, such as FDM, SLA, SLS, Polyjet, Carbon DLS, and HP multijet fusion.

• Used plastic materials include:

- ABS Like (resin)

- PC Like (resin)

- PP

- PP Like (resin)

- Nylon

- Silicone

- TPU

B. Subtractive manufacturing

• CNC machining: CNC machining (Computer Numerical Controlled machining) designates a process that uses a computer to control the trajectory of the machining tool. It employs many machining techniques, such as milling, drilling, and cutting.

• CNC Turning: This method uses a lathe to turn workpieces at high speeds and a tool with a special shape to remove layers of material from the workpiece. The workpiece shape is generally revolutionary. If the workpiece is long enough, an extra part is used to support the weight of the workpiece.

• CNC Milling: Milling is a process that uses a rotating tool to remove material from the fixed workpiece. There are two types of milling, horizontal and vertical milling.

• Used materials are:

- CPVC

- HDPE

- LDPE

- PC

- PP

- PVC

- PS

- PEI

- PET

- PMMA

- PTFE

- PS

- Nylon

C. Formative manufacturing

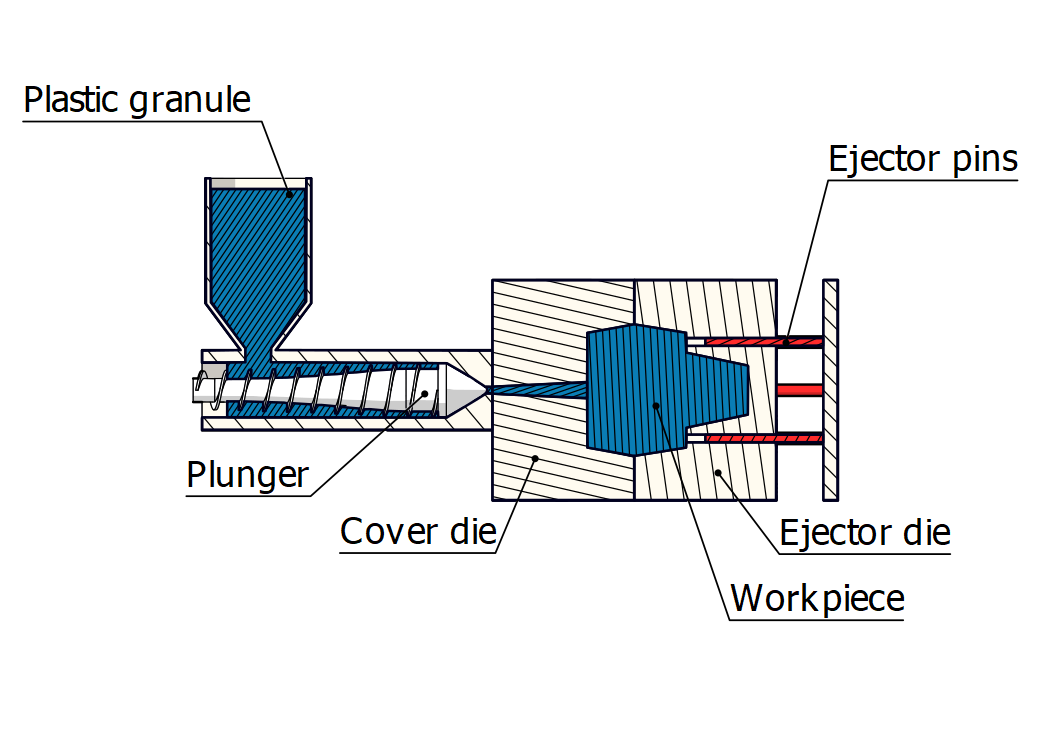

• Injection molding: In injection molding, molten plastic pellets are fed into a mold cavity under high pressure. After the plastic solidifies, the mold is opened to eject the part. Mold is made from hardened steel and contains the shape of the component to be molded. The Injection molding process is used for high and medium-volume production.

Injection molding

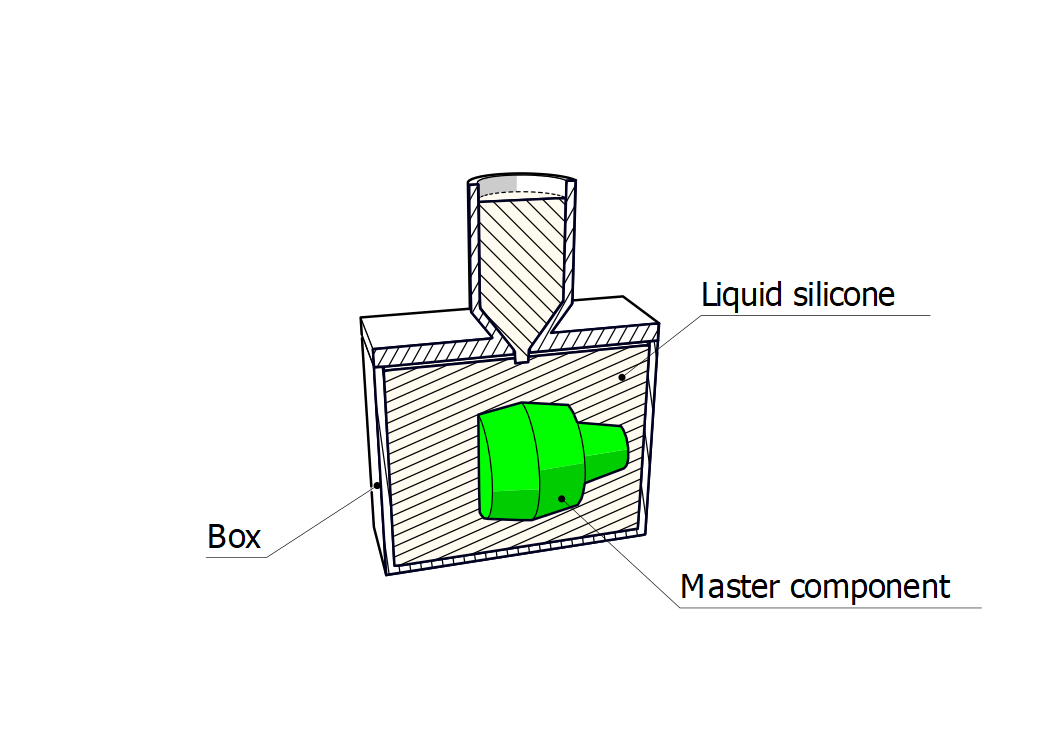

• Urethane Casting: Urethane Casting is a plastic molding process used to duplicate a master component submerged into liquid silicone. After the silicone mold solidifies, it is opened, and the master part is extracted. The mold is closed and injected with urethane, then gets heated to harden the urethane and extracted. Urethane Casting is used for low-volume production.

Urethane Casting

• Liquid silicone rubber molding: It is a rubber molding process that injects silicone and color into a mold, which is heated to solidify, then the part gets ejected. The mold is made from hardened steel and contains the body of the part to be molded. The liquid silicone rubber molding process is used for high and medium-volume production.

Liquid SiliconeRubber Molding

• We offer the following finishes for custom-manufactured parts:

- Textures

- Surface finish (smooth or matte)

- Inserting threads

- Pad printing

- Laser engraving

- Welding

- Clear coating

- Plating

- Assembly

- Testing

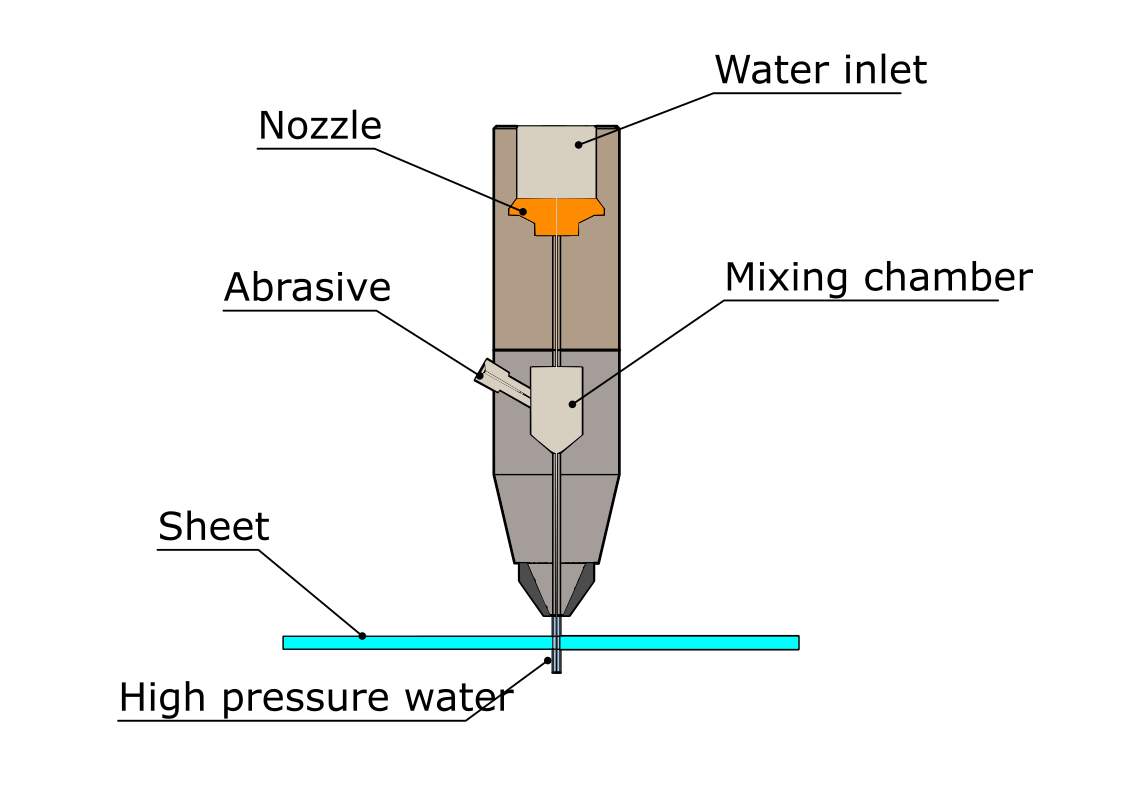

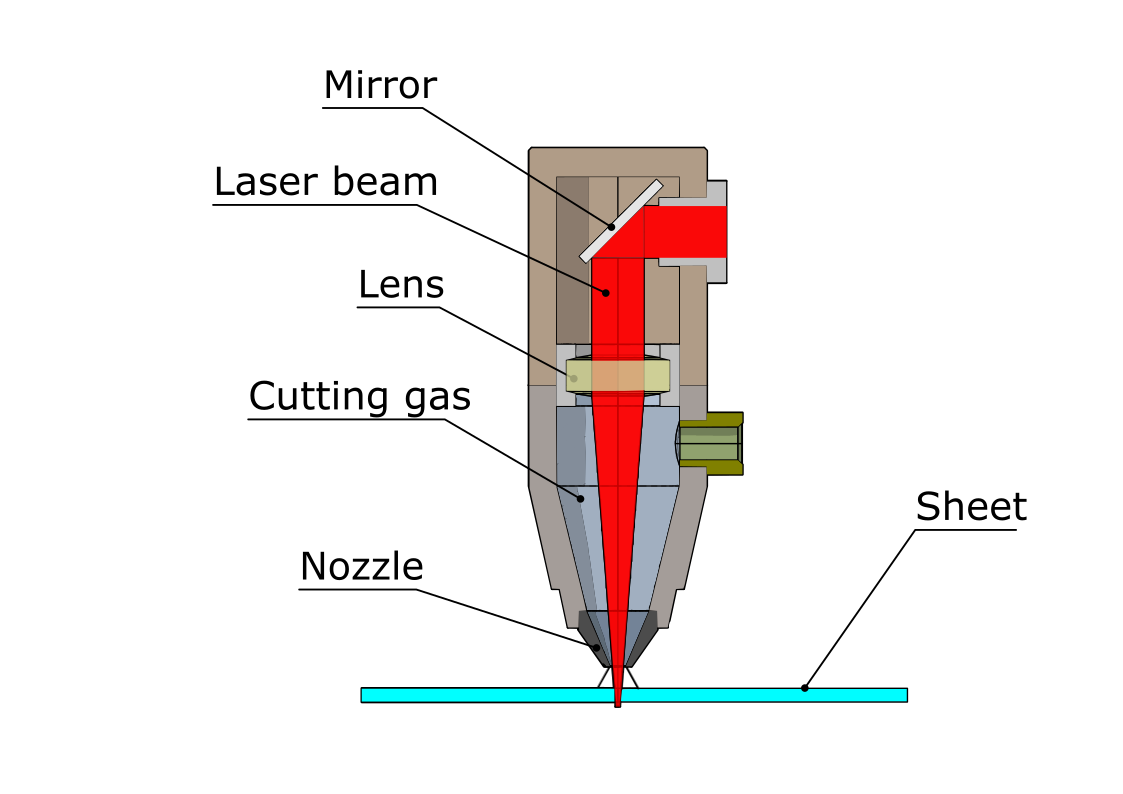

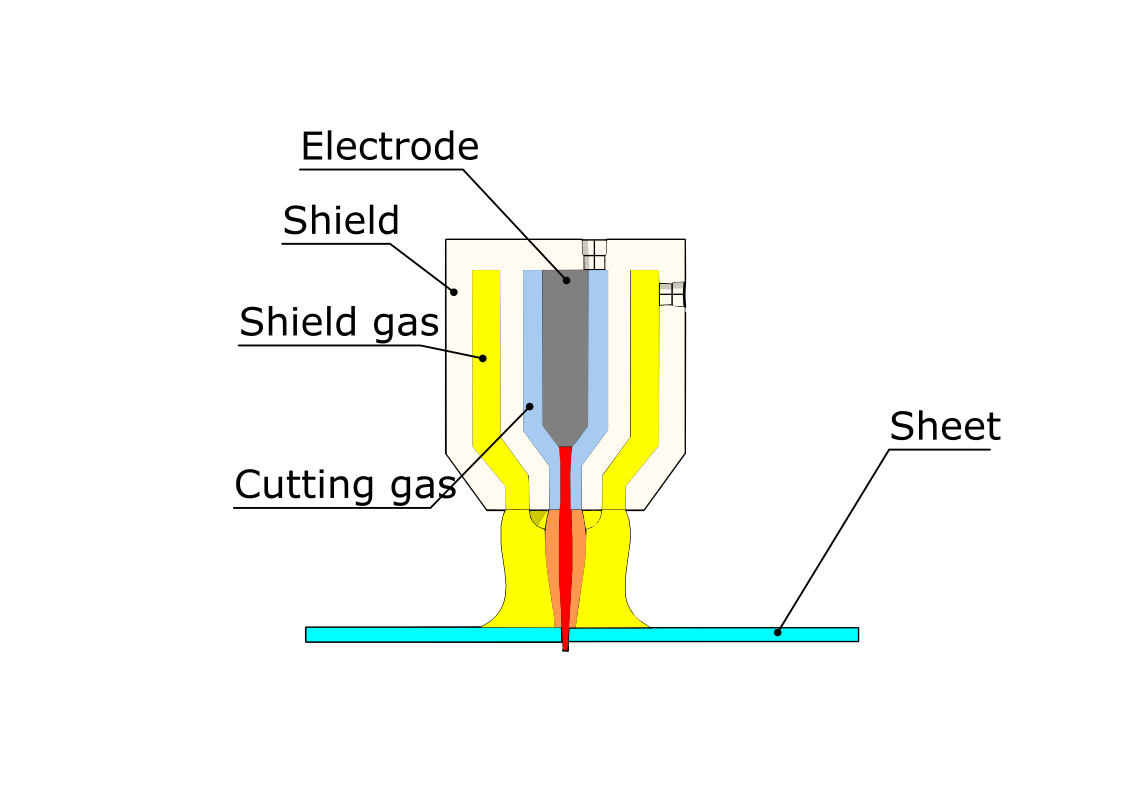

Waterjet, laser, and plasma cutting: It is a set of cutting methods that use heat or water to cut through all the materials listed above any type of material to produce a part or product.

The table below shows all the materials we use for every material, and the list is growing.

|

|

Material |

Sheet metal |

CNC Milling |

CNC Turning |

Die casting |

Metal extrusion |

3D Printing |

Injection molding |

|

Metals |

Titanium |

|

X |

X |

|

|

X |

|

|

Stainless steel |

X |

X |

X |

|

|

X |

|

|

|

Steel alloy |

|

X |

X |

|

X |

|

|

|

|

Aluminum |

X |

X |

X |

X |

X |

X |

|

|

|

Brass |

X |

X |

X |

|

|

|

|

|

|

Zinc |

|

|

|

X |

|

|

|

|

|

Magnesium |

|

|

|

X |

X |

|

|

|

|

Copper |

X |

X |

|

X |

X |

X |

|

|

|

Plastics |

Delrin (POM) |

|

X |

|

|

|

|

X |

|

PEEK |

|

X |

|

|

|

|

X |

|

|

ABS |

|

X |

|

|

|

|

X |

|

|

ABS Like |

|

|

|

|

|

X |

|

|

|

ABS/PC |

|

|

|

|

|

|

X |

|

|

CPVC |

|

X |

|

|

|

|

|

|

|

HDPE |

|

X |

|

|

|

|

X |

|

|

LCP |

|

|

|

|

|

|

X |

|

|

LDPE |

|

X |

|

|

|

|

X |

|

|

PC |

|

X |

|

|

|

|

X |

|

|

PC Like |

|

|

|

|

|

X |

|

|

|

PP |

|

X |

|

|

|

X |

|

|

|

PP Like |

|

|

|

|

|

X |

|

|

|

PVC |

|

X |

|

|

|

|

|

|

|

PPS |

|

|

|

|

|

|

X |

|

|

PS |

|

X |

|

|

|

|

X |

|

|

PSU |

|

|

|

|

|

|

X |

|

|

PEI |

|

X |

|

|

|

|

X |

|

|

PET |

|

X |

|

|

|

|

X |

|

|

PETG |

|

|

|

|

|

|

X |

|

|

PMMA |

|

X |

|

|

|

|

X |

|

|

PTFE |

|

X |

|

|

|

|

|

|

|

PS |

|

X |

|

|

|

|

X |

|

|

UHMW |

|

X |

|

|

|

|

|

|

|

Nylon (PA) |

|

X |

|

|

|

X |

X |

|

|

Elastomer & liquid silicone |

Silicone |

|

|

|

|

|

X |

|

|

LSR |

|

|

|

|

|

|

X |

|

|

TPE |

|

|

|

|

|

|

X |

|

|

TPU |

|

|

|

|

|

X |

X |

Norck's advanced CNC machining capabilities include precision turning, milling, grinding, and honing.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

The table below shows the finishes we offer.

|

|

Finish |

Sheet metal |

CNC Milling |

CNC Turning |

Die casting |

Metal extrusion |

3D Printing |

Injection molding |

|

Metals |

Surface finish (matte -> gloss) |

|

X |

X |

X |

|

|

|

|

Deburring |

X |

X |

X |

X |

X |

X |

|

|

|

plating |

|

X |

X |

X |

|

|

|

|

|

Anodizing |

X |

X |

X |

X |

|

|

|

|

|

Heat treatment |

X |

X |

X |

X |

X |

X |

|

|

|

Powder coating |

X |

X |

X |

X |

X |

X |

|

|

|

Painting |

X |

X |

X |

X |

X |

X |

|

|

|

Welding |

X |

X |

X |

X |

X |

X |

|

|

|

Riveting |

X |

|

|

|

|

|

|

|

|

Assembly |

X |

X |

X |

X |

X |

X |

|

|

|

Testing |

X |

X |

X |

X |

X |

X |

|

|

|

Plastics |

Mold textures |

|

|

|

|

|

|

X |

|

Surface finish (matte -> gloss) |

|

X |

X |

|

|

|

X |

|

|

Inserting threads |

|

X |

X |

|

|

X |

X |

|

|

Pad printing |

|

X |

X |

|

|

X |

X |

|

|

Laser engraving |

|

X |

X |

|

|

X |

X |

|

|

Welding |

|

X |

X |

|

|

X |

X |

|

|

Clear coating |

|

|

|

|

|

X |

X |

|

|

Plating |

|

X |

X |

|

|

X |

X |

|

|

Assembly |

|

X |

X |

|

|

X |

X |

|

|

testing |

|

X |

X |

|

|

X |

X |

Norck: Your Data-Driven Partner for On-Demand Manufacturing Excellence

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

- Precision CNC Machining: High-quality custom parts and components.

- Advanced 3D Printing: Rapid prototyping and complex production parts.

- Sheet Metal Fabrication: Custom fabrication solutions across materials.

- Injection Molding: Scalable production for plastic parts.

Why Choose Norck?

- AI-Powered Manufacturing: Data and AI optimize our processes for superior quality, minimized costs, and supply chain visibility

- Vast Production Capacity: Our extensive partner network in Europe and the US guarantees both low and high-volume production.

- End-to-End Expertise: Our team of engineers, data scientists, and product developers ensure design for manufacturability and unparalleled service

- Single-Source Solution: Norck streamlines your supply chain, reduces overhead, enhances purchasing power, and delivers just-in-time results.

- Online Custom Components Services: Norck's online custom components services provide a fast, easy, and reliable way to bring your ideas to life with high quality, custom made parts.

- Custom Components Services Near You: Your search for custom components service ends here. Norck offers tailored engineering and manufacturing support that begin with your unique project needs. Whether you're a local business or searching online, our expert team delivers top-quality, custom component solutions to bring your designs to life.

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

OUR SERVICES

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Looking for a reliable, lifelong supplier to manufacture your next custom metal parts? Click to learn more about Norck’s capabilities in On Demand CNC machining.

All industries including consumer products, electronics, energy, hardware, aerospace, defense, automotive, robotics, machinery are covered.

In a hurry to test before embarking on a full scale production or need high volume production? Turn to Norck for its advanced 3D printing and rapid prototyping services for your next project.

Get a quote for your next sheet metal part, custom part made with CNC machining, or 3D printing.

English

English