CNC Milling Tolerances & Standards

Norck’s advanced precision CNC milling capabilities allow us to manufacture high-accuracy components that meet strict industrial requirements. With state-of-the-art cnc milling machines, we achieve tolerances as tight as ±0.01 mm, depending on geometry and material. Our minimum feature size typically reaches 0.5 mm, ensuring clean edges and fine details even on complex parts. Standard surface finishes range from Ra 1.6 μm to Ra 3.2 μm, while enhanced finishing options can be applied upon request.

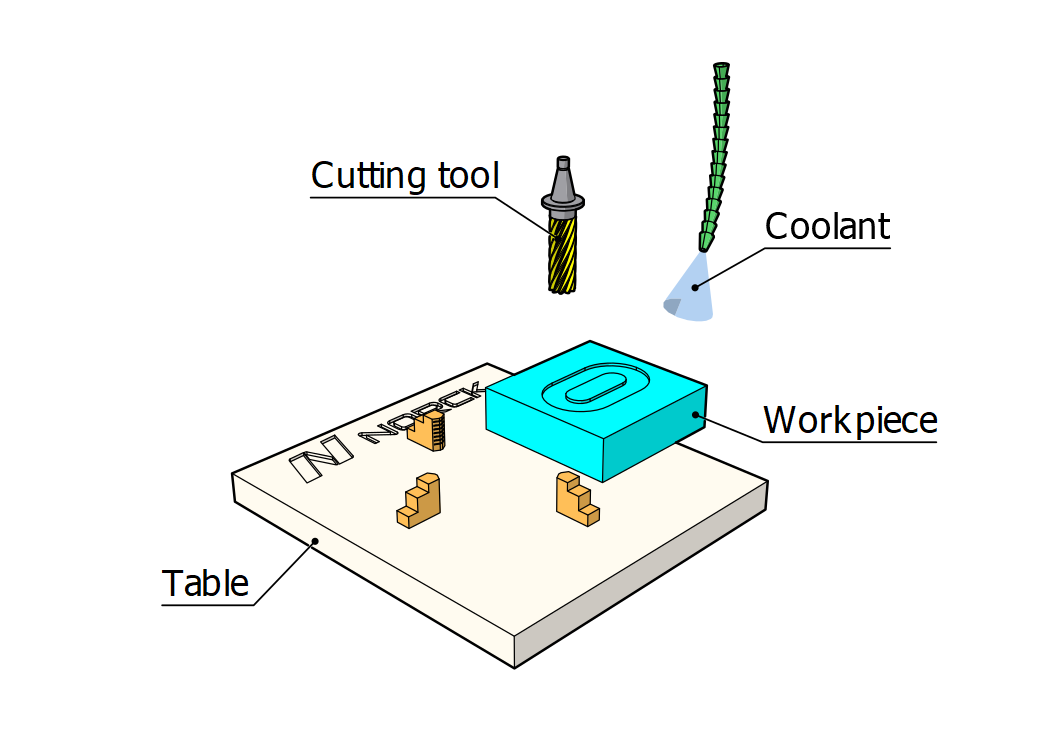

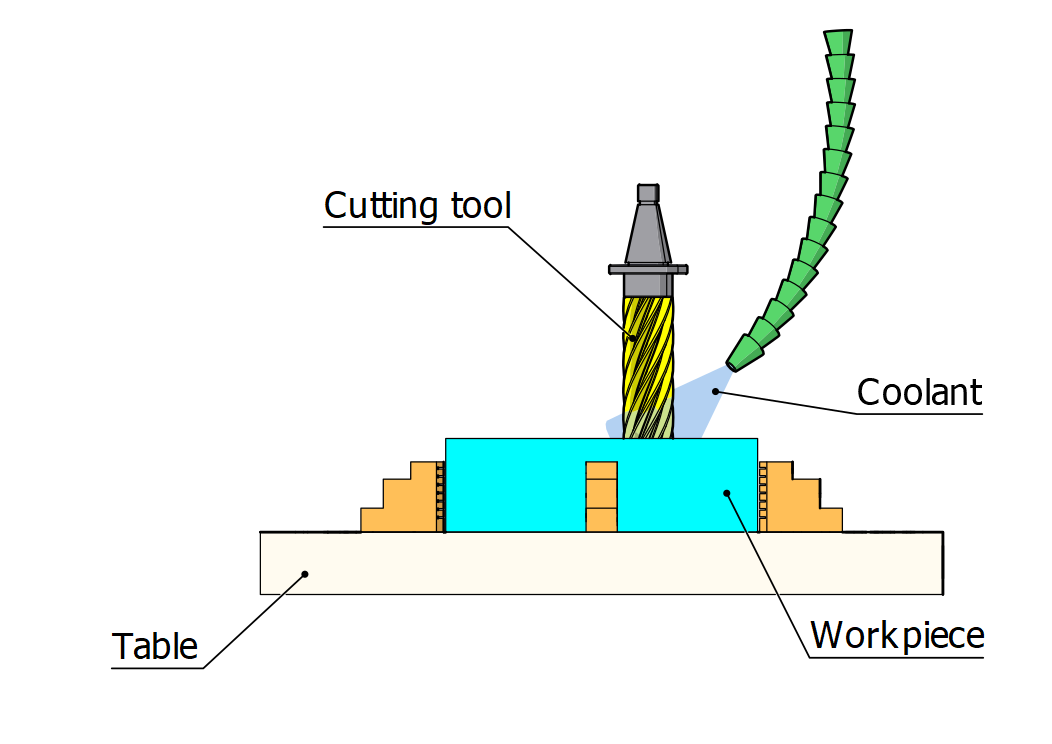

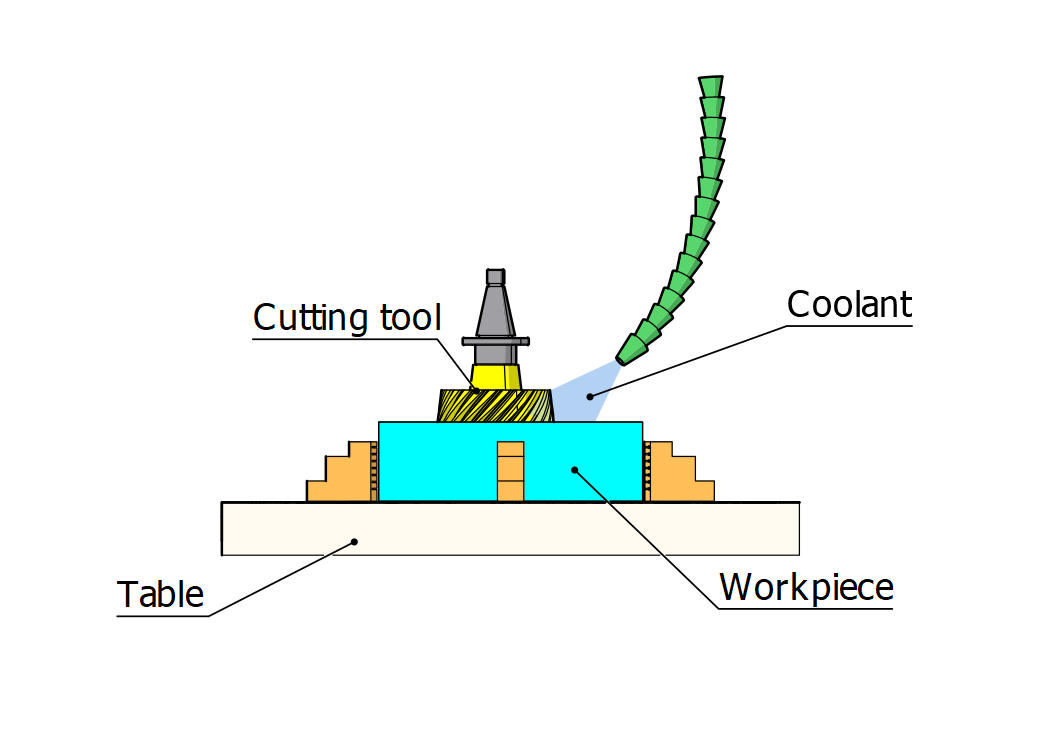

For larger components, our 3 axis CNC milling machine, 4 axis CNC milling machine, and 5 axis CNC milling machine platforms support maximum part dimensions up to 1000 x 600 x 500 mm, making Norck a versatile and capable cnc milling company. These specifications can also be presented using tables or visual diagrams for improved clarity whenever needed.

Types of CNC Mills

Modern manufacturing relies on a wide range of cnc milling machines designed to handle different geometries, tolerances, and production volumes. Each machine type—whether 3 axis cnc milling machine, 4 axis cnc milling machine, or 5 axis cnc milling machine—offers unique advantages for shaping metal and plastic components with precision. As a professional cnc milling company, Norck selects the ideal platform based on part complexity, material requirements, and customer specifications. Our goal is to ensure efficient machining, optimized cycle times, and high-quality cnc milling parts that meet demanding industrial standards. Below, you will find detailed explanations of each CNC mill type and their specific capabilities.

3-Axis CNC Mills

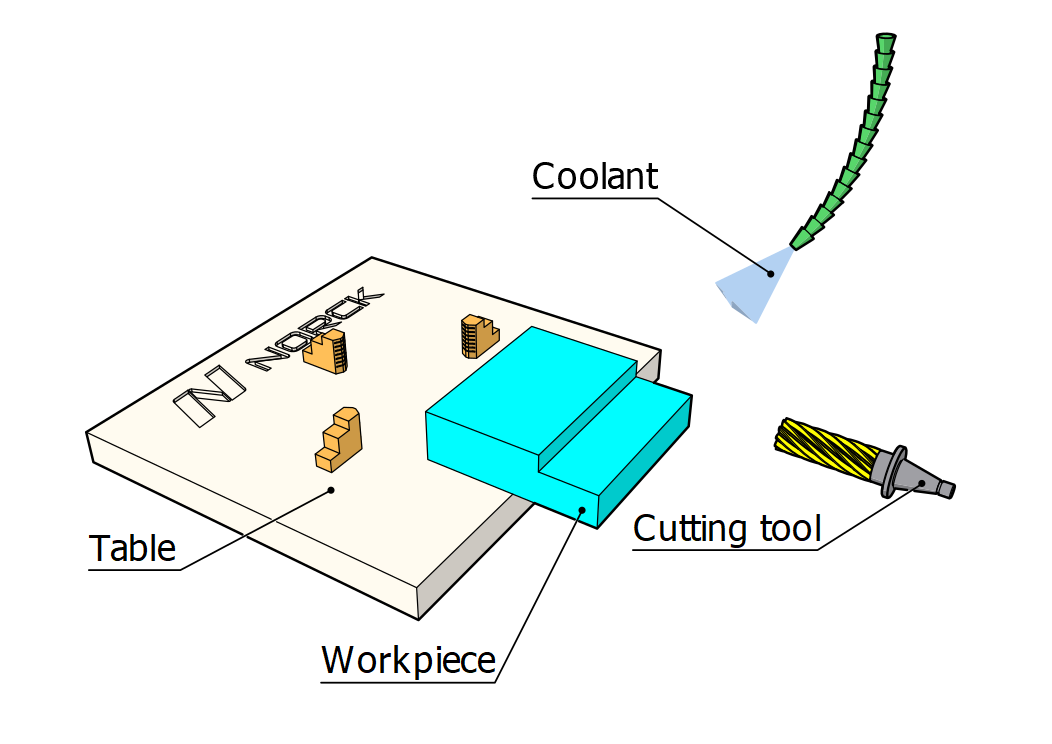

A 3 axis CNC milling machine is the most common and versatile setup used in modern manufacturing. It operates along the X, Y, and Z axes, allowing efficient machining of flat surfaces, slots, pockets, and basic contours. These mills are ideal for producing standard cnc milling parts with consistent accuracy and cost efficiency. At Norck, we utilize advanced cnc milling machines to ensure reliable performance for prototypes and mid-volume production runs. While simpler than multi-axis systems, 3-axis platforms remain a powerful choice for projects that prioritize precision, shorter lead times, and competitive pricing within our broader cnc milling service offering.

4-Axis CNC Mills

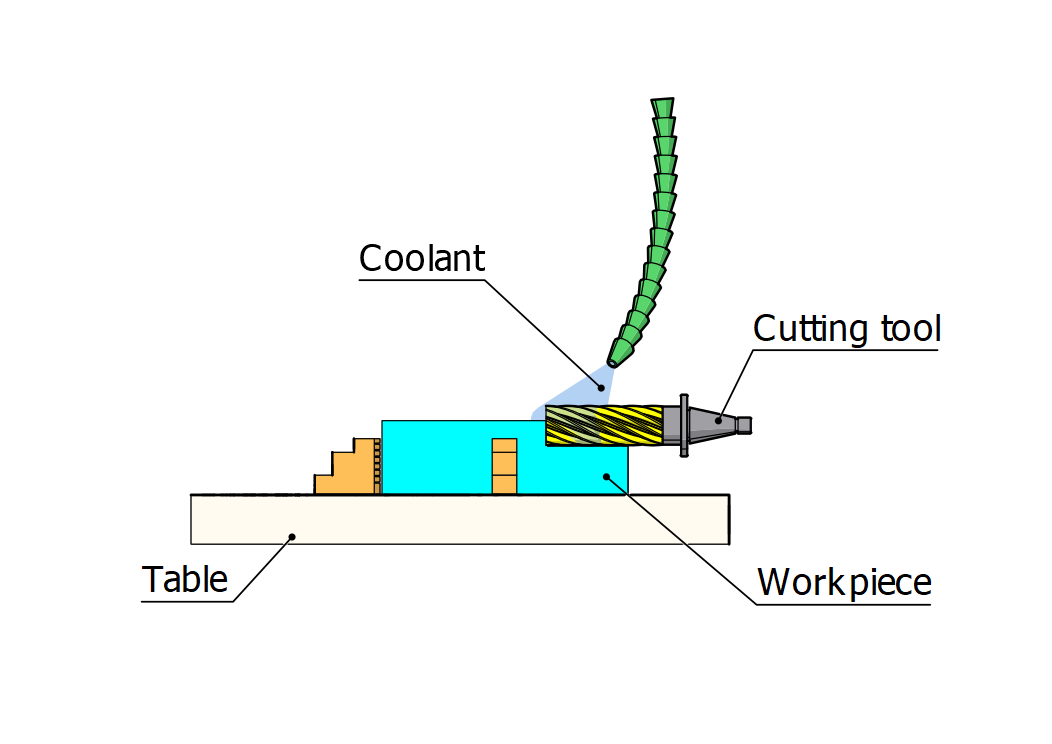

A 4 axis CNC milling machine adds rotational movement to traditional 3-axis machining, enabling the part to turn around one additional axis. This capability makes it ideal for machining cylindrical components, curved surfaces, and features that require angular positioning. Norck leverages high-performance milling machine CNC systems to deliver improved efficiency and reduced setups, lowering overall manufacturing time and custom CNC milling cost. With enhanced flexibility, 4-axis mills are perfect for producing more complex cnc milling parts online, supporting industries that require precision and moderate geometric complexity without the full cost of multi-axis machining.

5-Axis CNC Mills

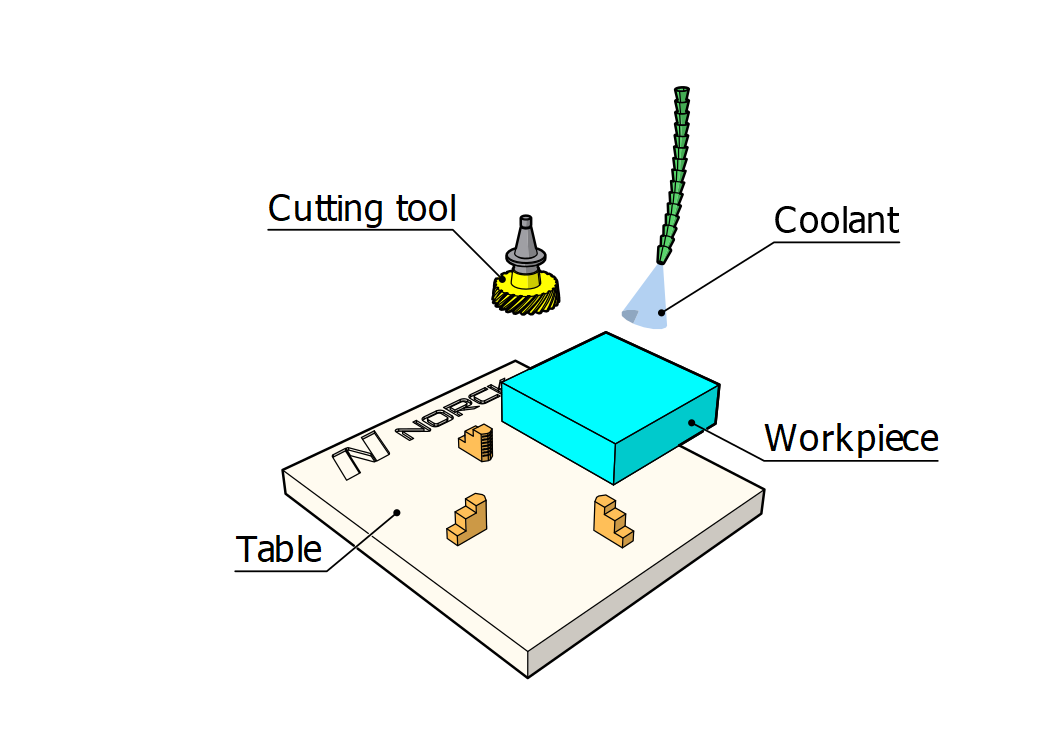

A 5 axis CNC milling machine provides the highest level of flexibility, enabling simultaneous movement across five different axes. This makes it essential for producing highly complex geometries, deep cavities, turbine-style components, and parts requiring tight tolerances. As an advanced cnc milling company, Norck uses 5-axis technology to reduce multiple setups, improve accuracy, and achieve superior surface quality. Ideal for aerospace, medical, and high-precision applications, 5-axis machining delivers unmatched performance within our precision CNC milling capabilities. Whether for prototypes or full production, it ensures the most efficient and innovative results in modern cnc machining milling.

CNC Milling Materials

Aluminum

- Excellent machinability and lightweight structure

- Strong corrosion resistance

- Supports tight tolerances and smooth surface finishes

- Commonly used in aerospace, automotive, and electronics industries

Stainless Steel

- Exceptional strength, wear resistance, and high-temperature durability

- More challenging to machine, but modern CNC systems ensure precision

- Ideal for medical devices, industrial equipment, and high-stress components

Carbon Steel

- Strong mechanical properties

- Delivers accurate machining performance with proper tooling

- Frequently used for structural and load-bearing parts

Brass

- Easy to machine with excellent dimensional stability

- Provides smooth surface finishes

- Typically used for valves, fittings, precision connectors, and decorative components

Titanium

- High strength-to-weight ratio

- Outstanding corrosion resistance

- Suitable for demanding aerospace and medical applications

Plastics (ABS, Nylon, POM)

- Lightweight, cost-effective, and clean machining properties

- Suitable for prototypes and functional parts

- Ideal for applications requiring insulation, impact resistance, or chemical stability

Custom CNC Milling Cost Overview

The pricing structure for Norck’s custom CNC milling services is designed to be transparent, flexible, and fully aligned with each project’s technical requirements. Instead of providing fixed pricing, we calculate the custom CNC milling cost based on factors such as material type, part geometry, tolerances, machine setup time, and production volume. Customers can upload their models to receive a detailed cost breakdown before placing an order. Using our digital workflow, the total cost of CNC milling machine time, tooling, and finishing operations is clearly reflected in every quote. This ensures customers understand how each element affects their final cost, resulting in an efficient, predictable, and user-friendly ordering experience.

English

English