Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

This guide will help you prepare your sheet metal parts for manufacturing.

Design for manufacturing, known as DFM, ensures that the components you design can be manufactured, which is crucial for outsourcing. It helps reduce the revisions and turnarounds.

Material Selection

- Stainless steel

- Steel (not treated)

- Galvanized steel

-Aluminum

- Brass

- Copper

Finishes: Norck offer the finishes below for your sheet metal components :

- Welding sheet metal components with MIG and TIG

- Riveting

- Powder coating

- Plating

Gauge: Gauge indicates the thickness of sheet metal, depending on the material.For example, in Stainless Steel, Gauge 18 is a thickness of 1.270mm, while in aluminum, Gauge 18 equals1.024mm.

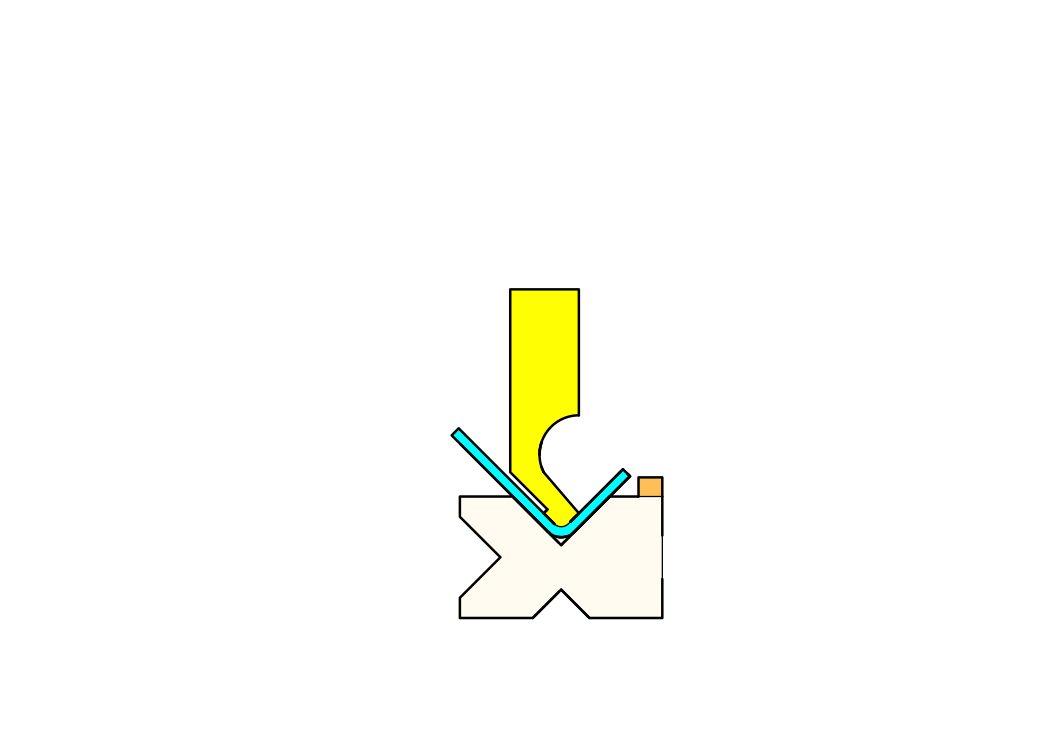

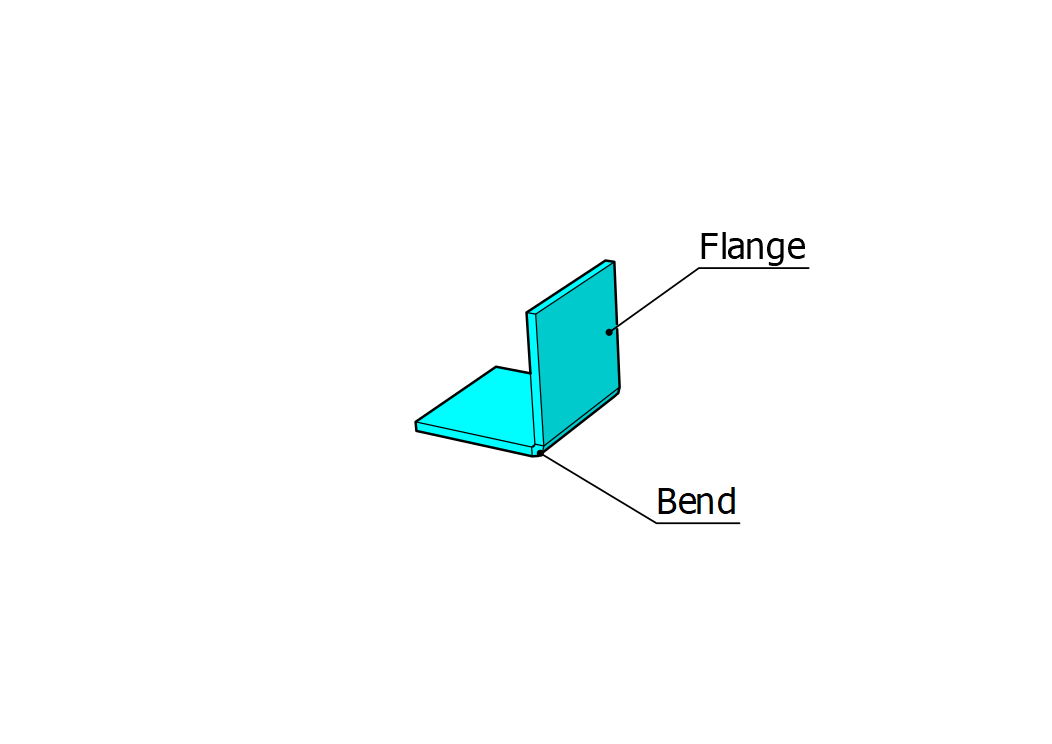

Bend: A bend is the deformation of a sheet over an axis. It is made using a punch and a die.

Flange: A flange is a formed part of sheet metal. It is made using bending.

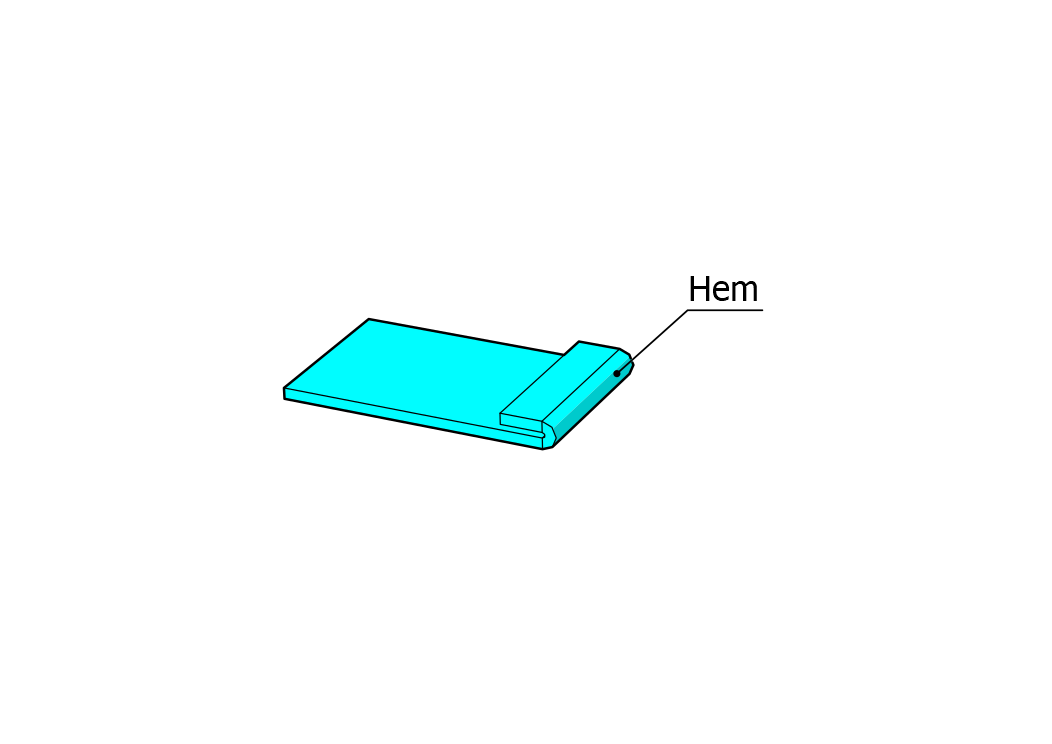

Hems: A hem a rolled edge, the sheet metal is rolled until it is flush to itself. It is made by bending the sheet metal to 180°.

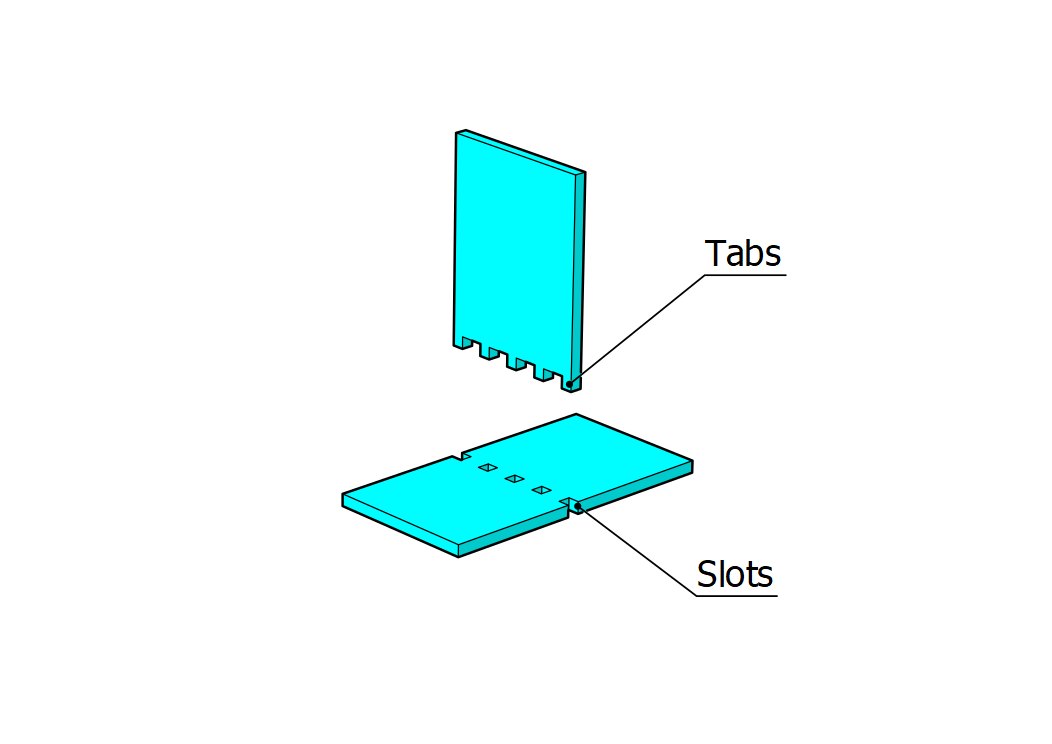

Tabs: A tab is a small shape extruded from sheet metal. It is used to reinforce the part or to add extra functionality.

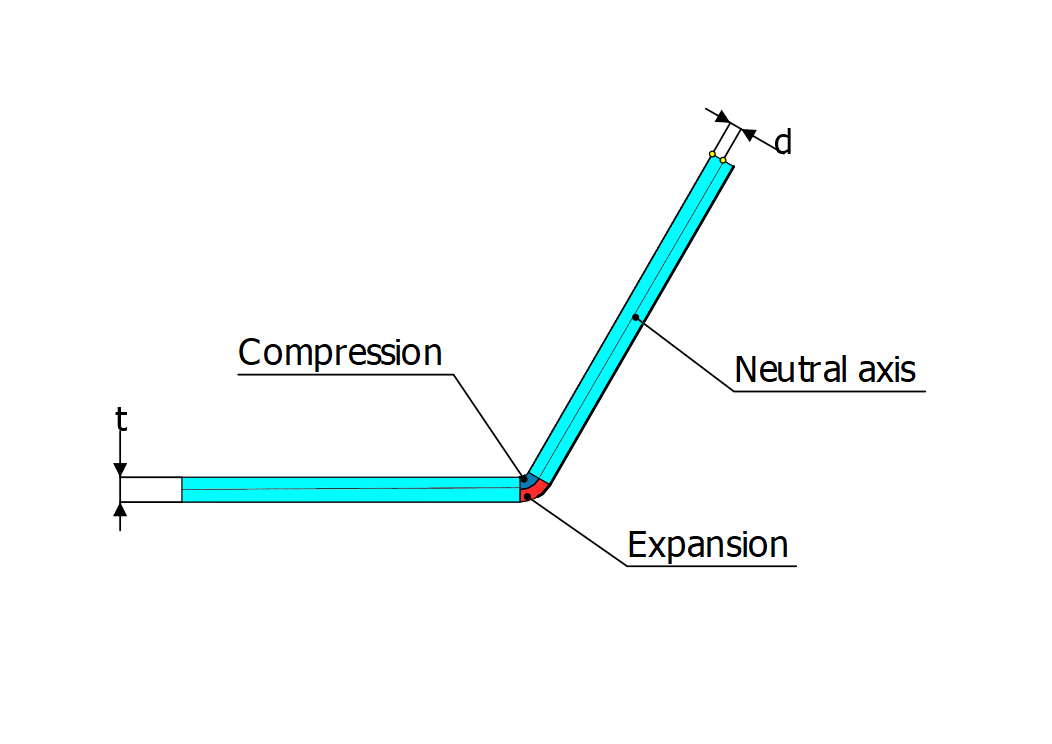

Neutral axis and K-factor: A sheet metal part is submitted to compression and expansion forces when bending.

The neutral axis is a section in which there are no forces, and its position varies according to the material of the sheet metal.

K factor is a ratio of the distance between the neutral axis on the thickness of the sheet.

It is calculated as follows => K = d/t

To ensure that your designed parts can be manufactured, you must keep the best practices to improve the manufacturability and get high-quality products.

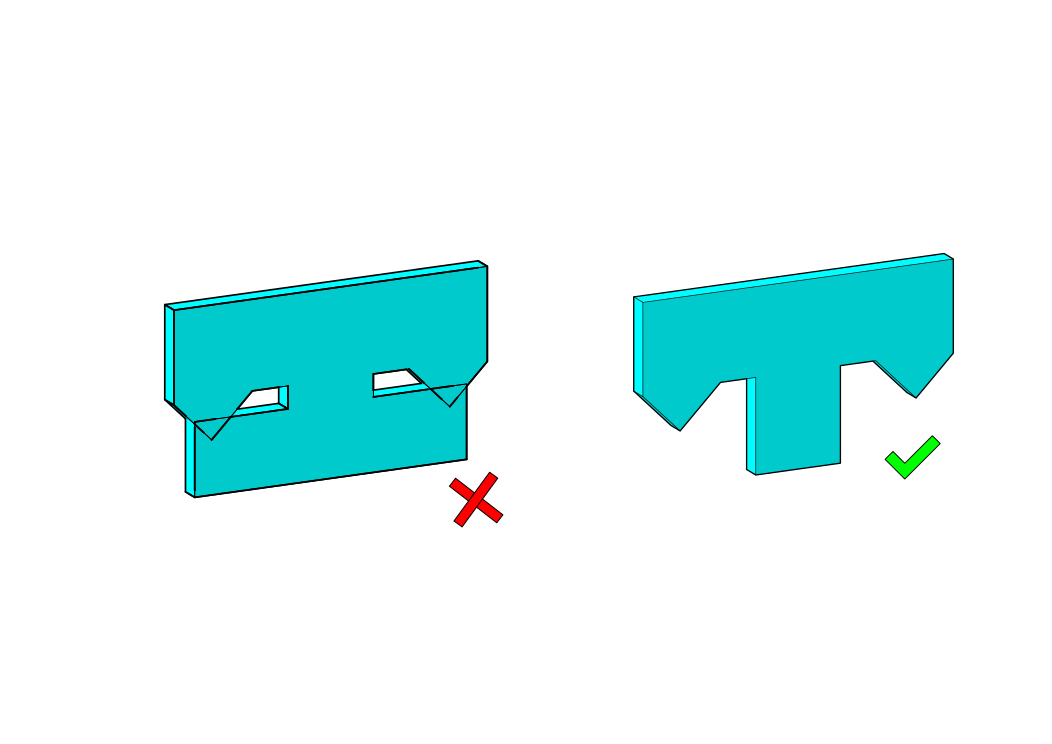

Flat pattern: A flat pattern must not intersect.

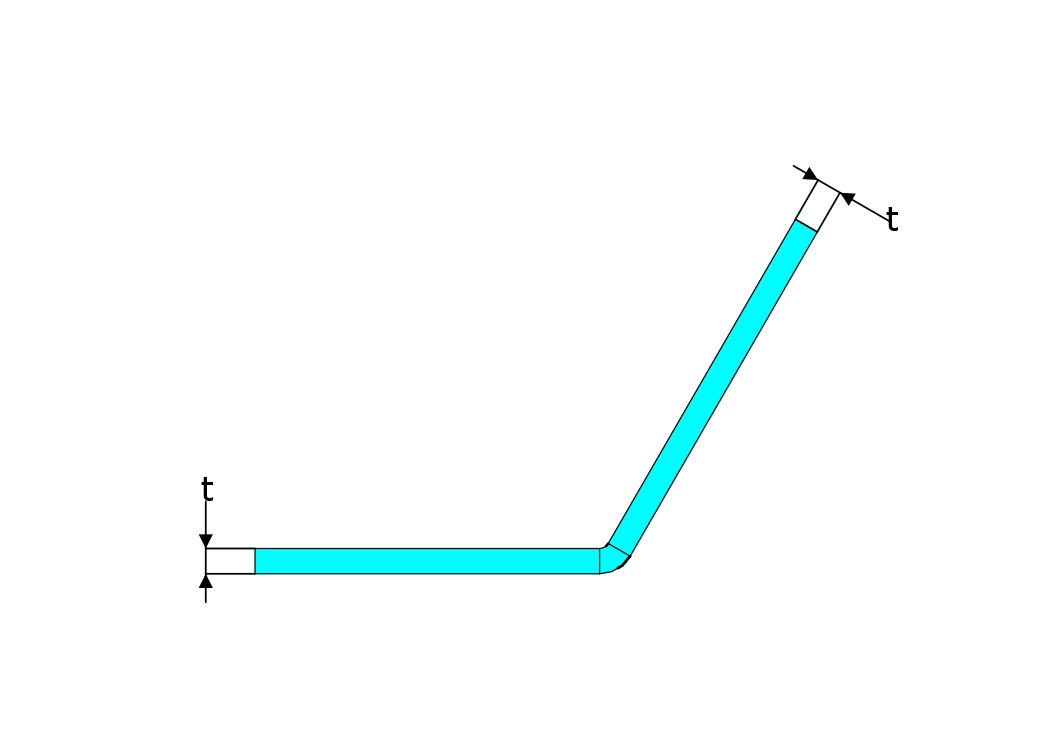

Uniform wall thickness: Parts are formedfrom a metal sheet, and the designed pieces should have the same thickness (t).Recommended sheet metal thickness range from 0.02 to 0.3inches.

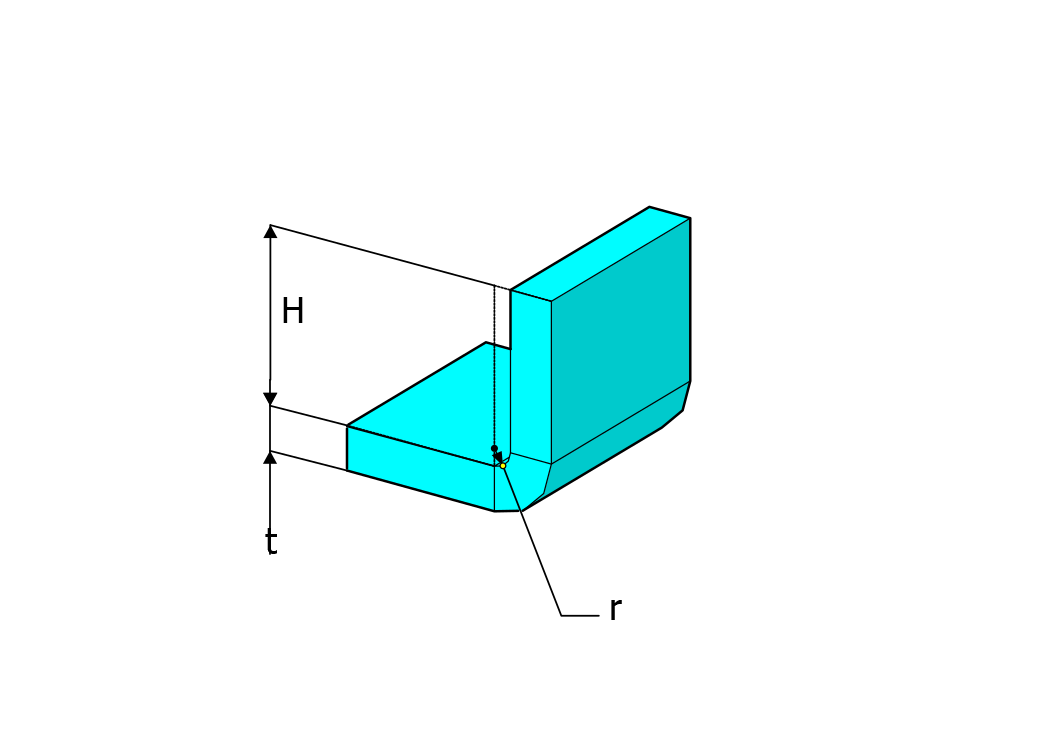

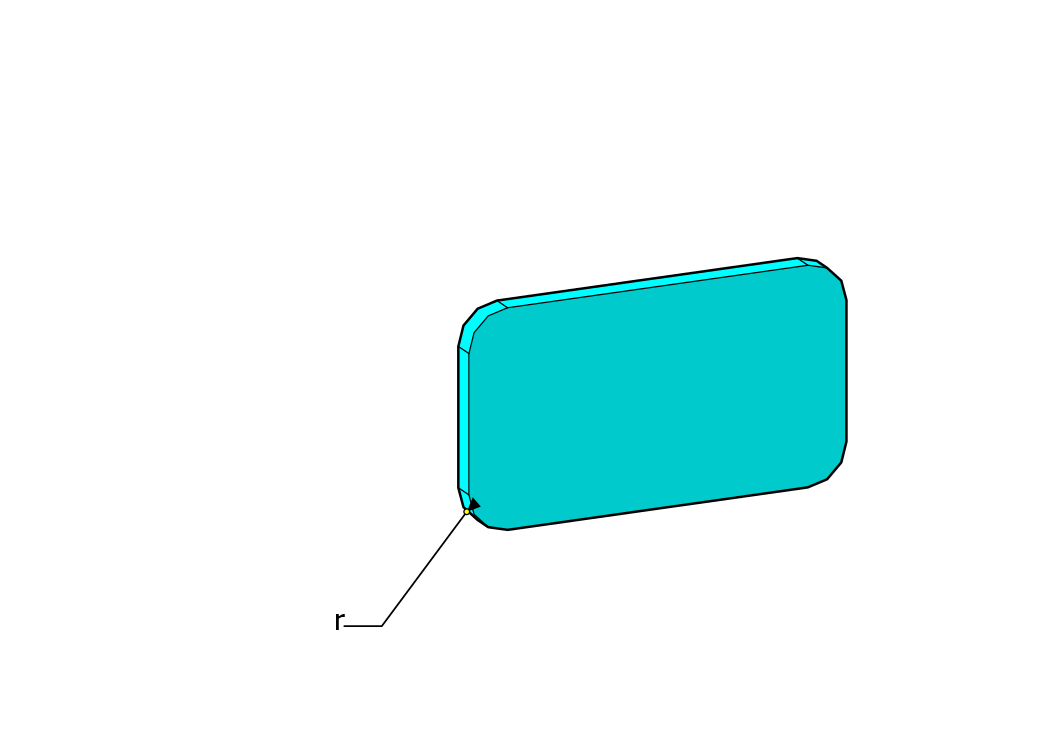

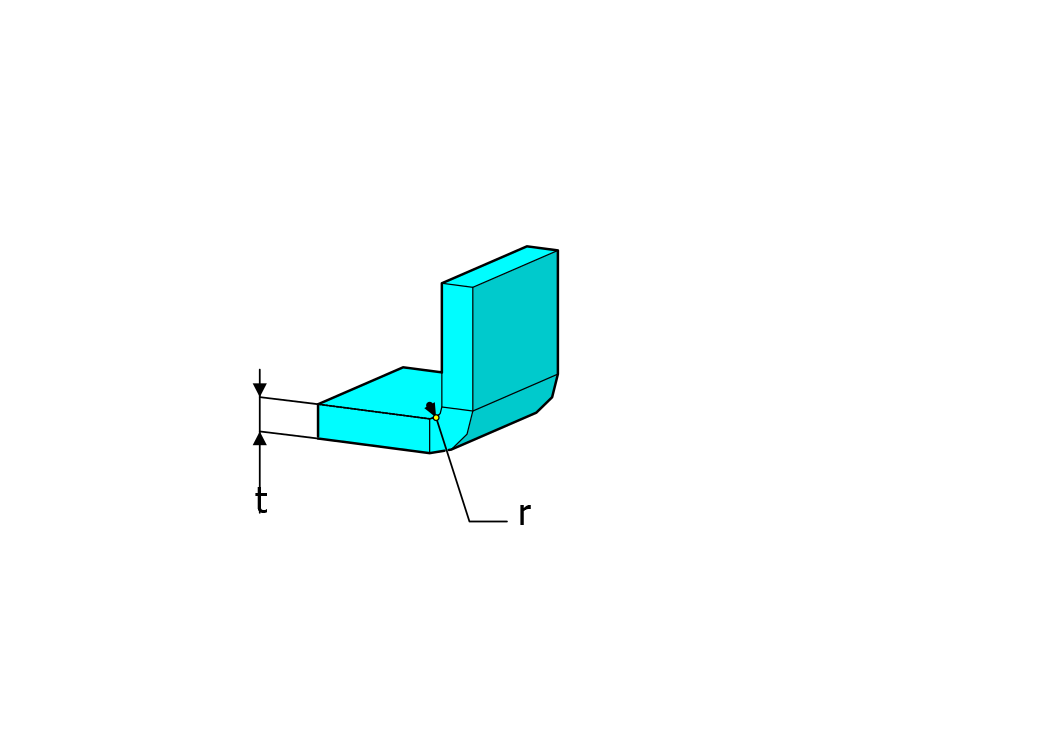

Bend radius (Radii): Sheet metal parts should have a bend radius to avoid cracking. Bend radius (r) should be between one to two times sheet thickness (t): 2t >= r => t

Add corner: Sheet metal parts can have sharp edges. Adding corners to break sharp edges is a goodthing that can protect users and gives a smooth finish to parts.

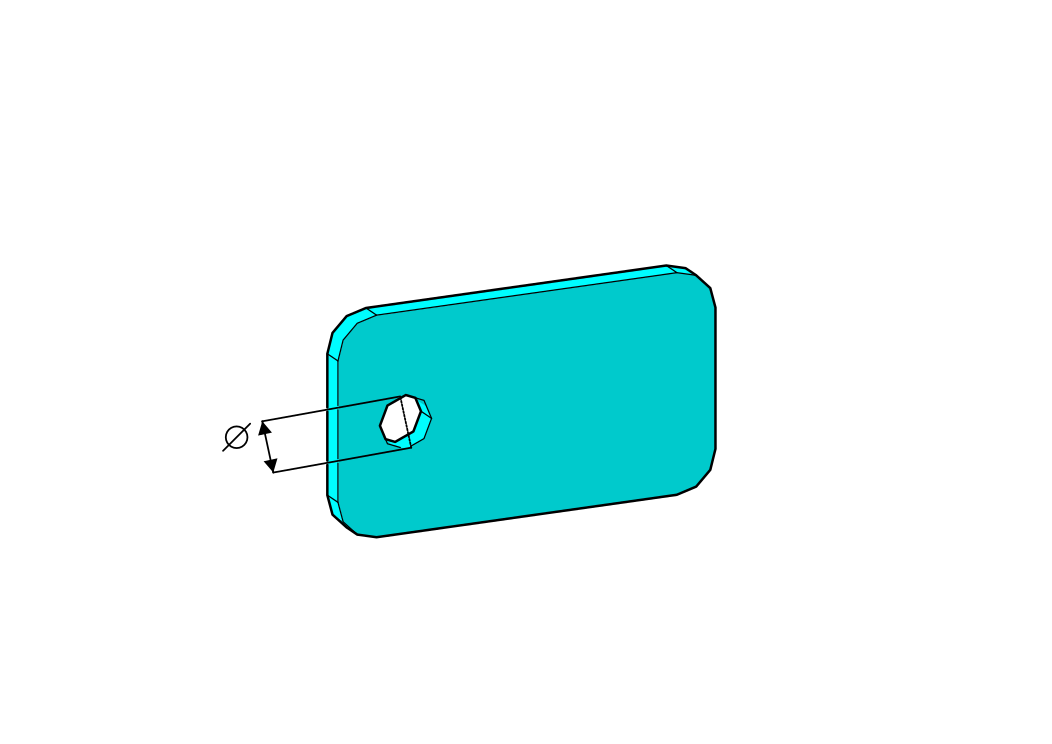

Minimum hole diameter: Having holes diameters less than sheet thickness can result in deformation in the workpiece. The recommended diameter should be greater than the sheet thickness: D >= t

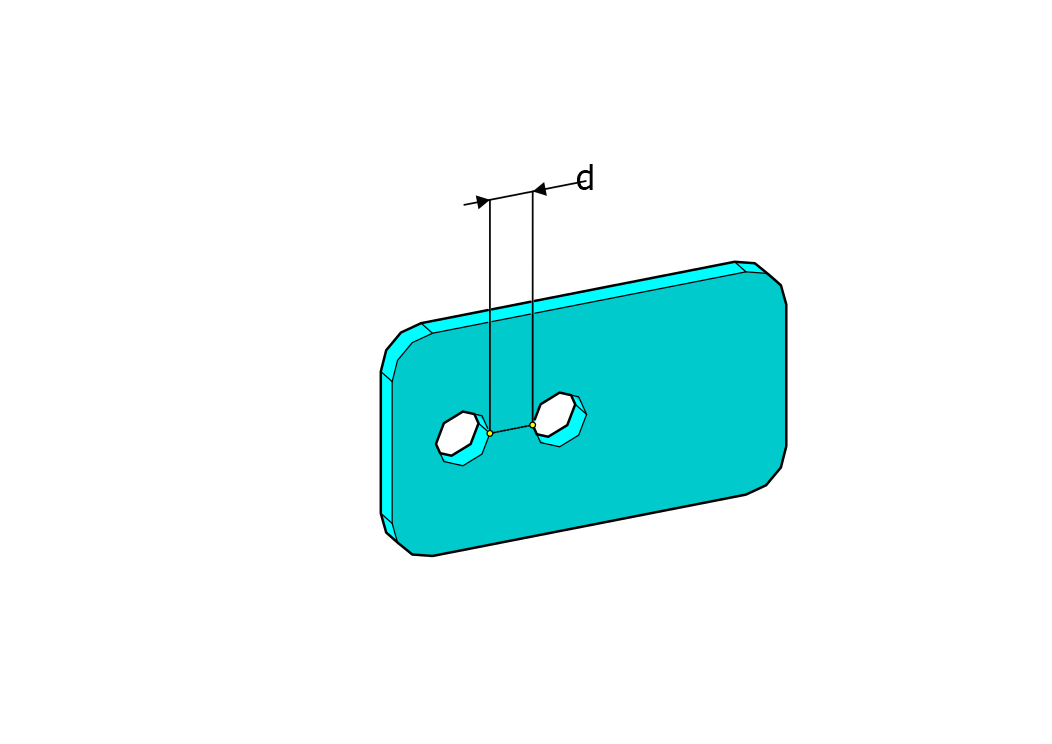

Distance between holes: Distance between holes must be at least three times the thickness: d >= 3t

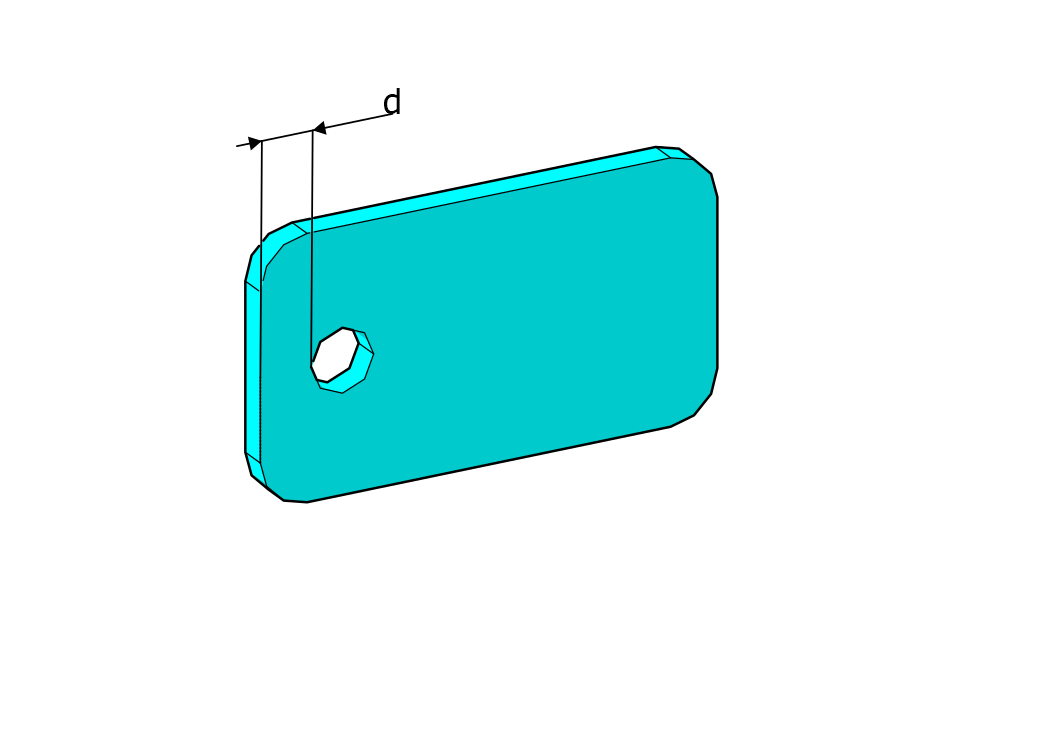

Distance between holes and edges: The distance between the hole and edge should be greater than the thickness of the sheet: d >= t

Minimum height bend: Bends should be higher than the sum of two times the thickness plus the radius: B = 2t + r

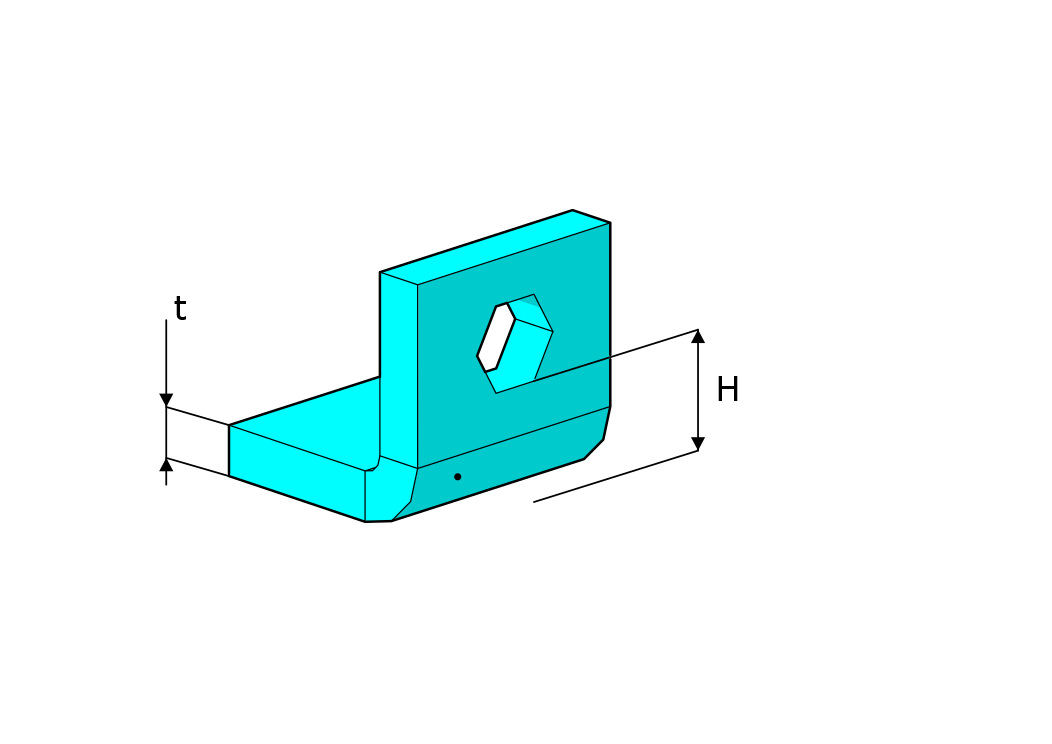

Distance between holes and bends: The height of holes (H) should be more than three times the thickness (t): H > 3t

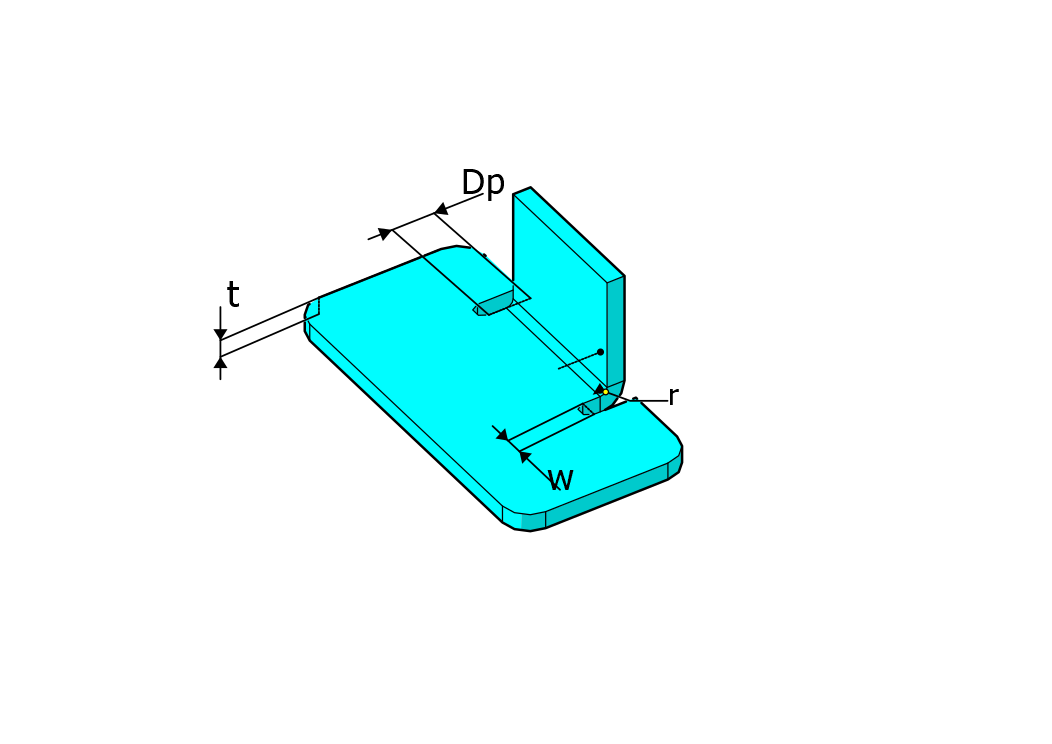

Bending relief: A bend relief is a cut made next to a bend when there’s a material on either side to prevent tearing and sheet deformation when bending. Bend relief depends on the thickness and material.Bend relief width (w) must be one and a half times sheet thickness (t). Bend relief (Dp) must exceed the bend: 1.5 >= w >= t and Dp >= t + r

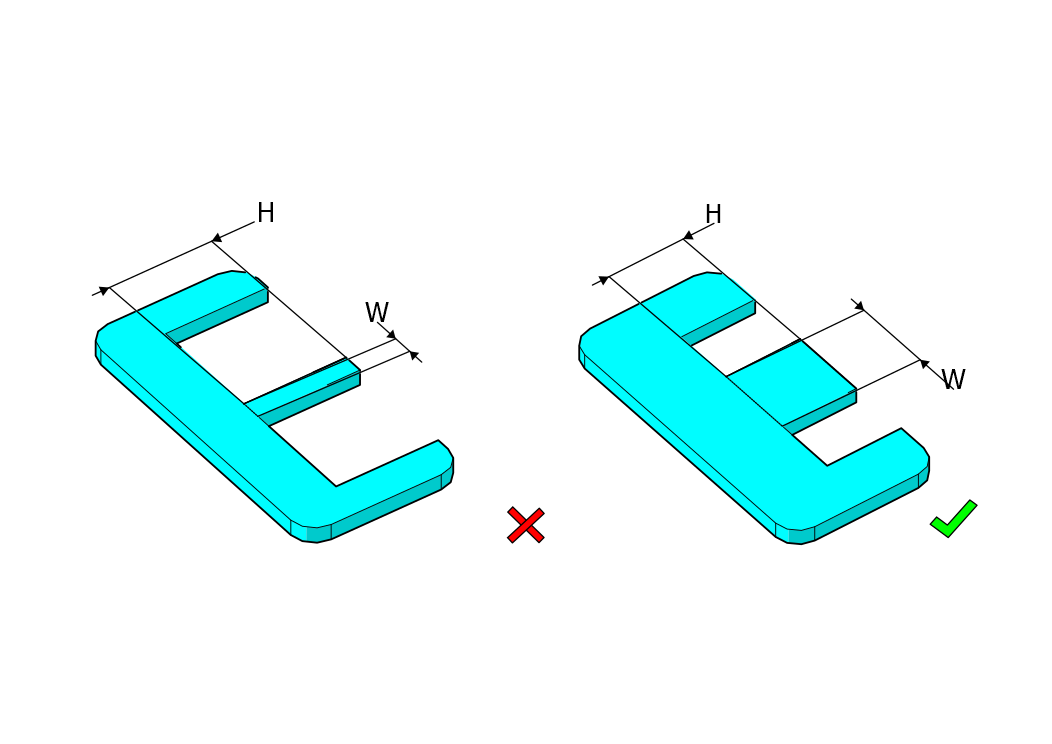

Notches: Notching width should be greater than sheet thickness (t), and its height(H) shouldn’t exceed five times its width (W): w => t, and H >= 5t.

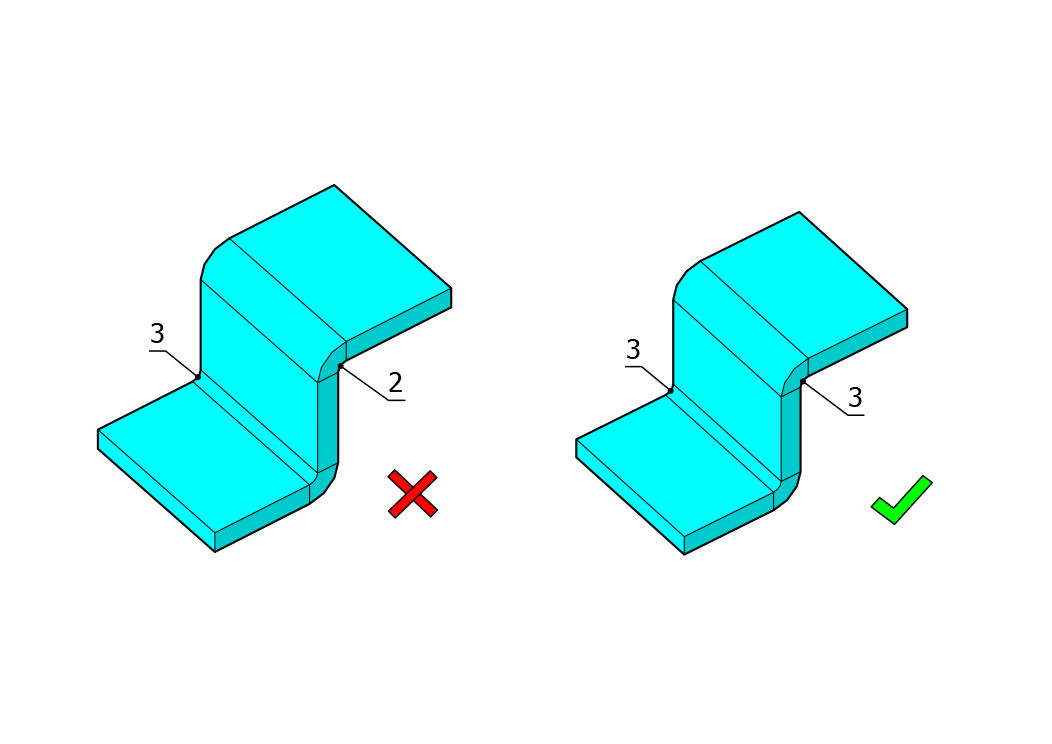

Bend consistency: Keeping the same bend radius across all bends is more effectivein minimizingbending costs.

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.