Injection Molding: Norck's Expertise in Transforming Ideas into Precision Plastic Parts

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of intricate plastic components with exceptional precision and efficiency. From everyday consumer goods to critical medical devices and industrial components, injection-molded parts play a vital role in our lives. Norck, a leader in precision manufacturing, is at the forefront of this technology, offering comprehensive injection molding solutions that empower businesses across various industries to bring their product visions to life.

The Art and Science of Injection Molding

Injection molding is a process where molten plastic is injected under high pressure into a mold cavity, where it cools and solidifies into the desired shape. This versatile process can produce a wide variety of parts, from simple shapes to complex geometries with intricate details. Injection molding offers several key advantages:

- High Production Volumes: It enables the rapid production of large quantities of parts with consistent quality, making it ideal for mass production.

- Design Flexibility: Injection molding allows for the creation of complex part geometries with intricate features, including undercuts, threads, and living hinges.

- Material Versatility: A wide range of plastic resins can be used for injection molding, each with its unique properties and characteristics, allowing for customization to meet specific requirements.

- Cost-Effectiveness: Injection molding offers cost savings for high-volume production due to lower labor costs and material waste.

Get a Quote

Norck's Injection Molding Expertise

Norck's commitment to quality, innovation, and customer satisfaction is evident in its injection molding capabilities. With a deep understanding of materials, processes, and industry requirements, Norck provides comprehensive injection molding solutions that meet the highest standards of precision and performance.

Here's what sets Norck apart:

- State-of-the-Art Equipment: Norck invests in cutting-edge injection molding machines equipped with advanced features such as precise temperature control, high injection pressures, and multi-cavity molds. This allows for the production of high-quality parts with tight tolerances and consistent dimensions.

- Experienced Team: Norck's team of engineers, mold designers, and technicians possess extensive experience in injection molding. They work collaboratively with clients to optimize designs for manufacturability, select the right materials, and ensure that the final products meet or exceed expectations.

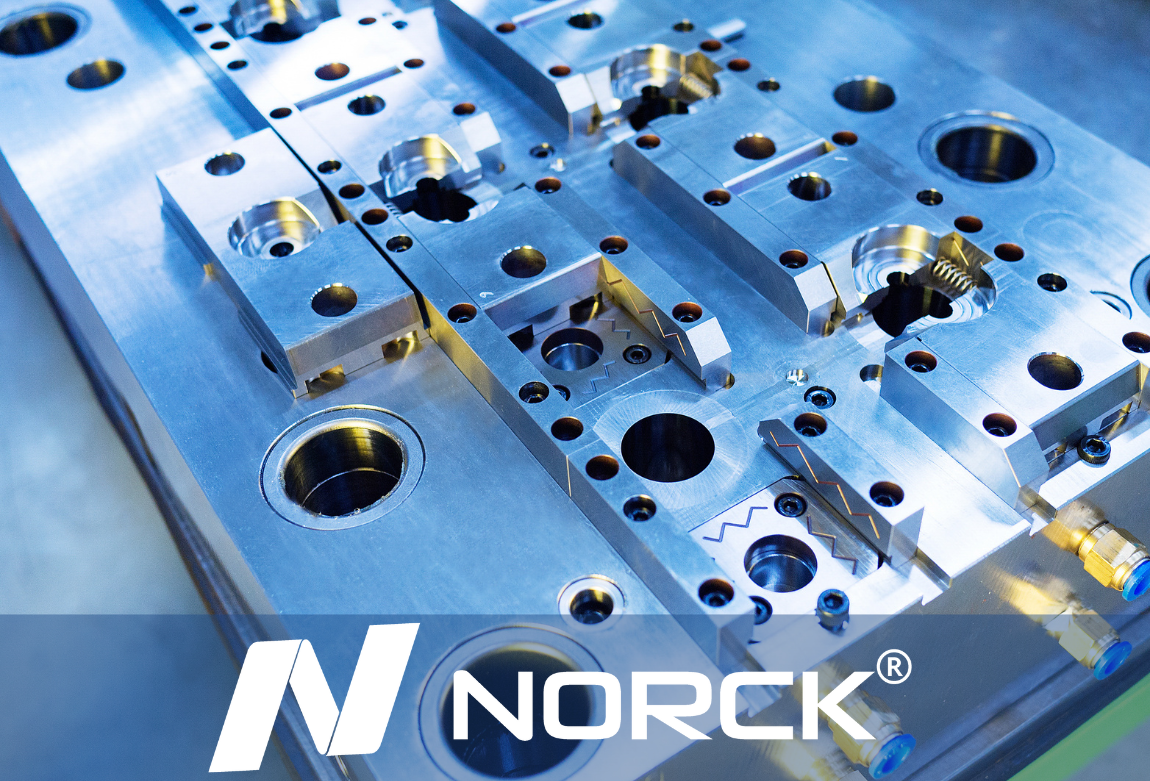

- Mold Design and Manufacturing: Norck offers in-house mold design and manufacturing services, ensuring that molds are optimized for the specific part geometry, material, and production requirements. They utilize advanced CAD/CAM software and precision machining techniques to create high-quality molds that deliver consistent results.

- Materials Expertise: Norck works with a wide range of plastic resins, including commodity plastics (such as polyethylene and polypropylene), engineering plastics (such as ABS and nylon), and high-performance plastics (such as PEEK and Ultem). They can advise clients on the best material choices based on their specific needs and requirements.

- Value-Added Services: Norck offers a range of value-added services, including assembly, finishing, packaging, and logistics, to provide clients with a complete end-to-end solution.

Applications of Norck's Injection Molding

Norck's injection molding capabilities are utilized in various industries, including:

- Automotive: Interior and exterior trim components, electrical connectors, engine parts, and lighting components.

- Medical: Medical device housings, surgical instruments, diagnostic equipment, and drug delivery devices.

- Consumer Goods: Electronics enclosures, appliance parts, toys, sporting goods, and household items.

- Industrial: Machinery components, electrical connectors, housings, and gears.

Get a Quote

Conclusion

Injection molding is a powerful manufacturing process that enables the mass production of high-quality plastic parts. Norck's expertise in this field, coupled with their commitment to innovation and customer satisfaction, makes them the ideal partner for businesses seeking reliable injection molding solutions. Whether you need prototypes for new product development or high-volume production runs, Norck has the expertise and capabilities to deliver results that meet and exceed your expectations.

English

English