• Used materials are:

• CPVC

• HDPE

• LDPE

• PC

• PP

• PVC

• PS

• PEI

• PET

• PMMA

• PTFE

• PS

• Nylon

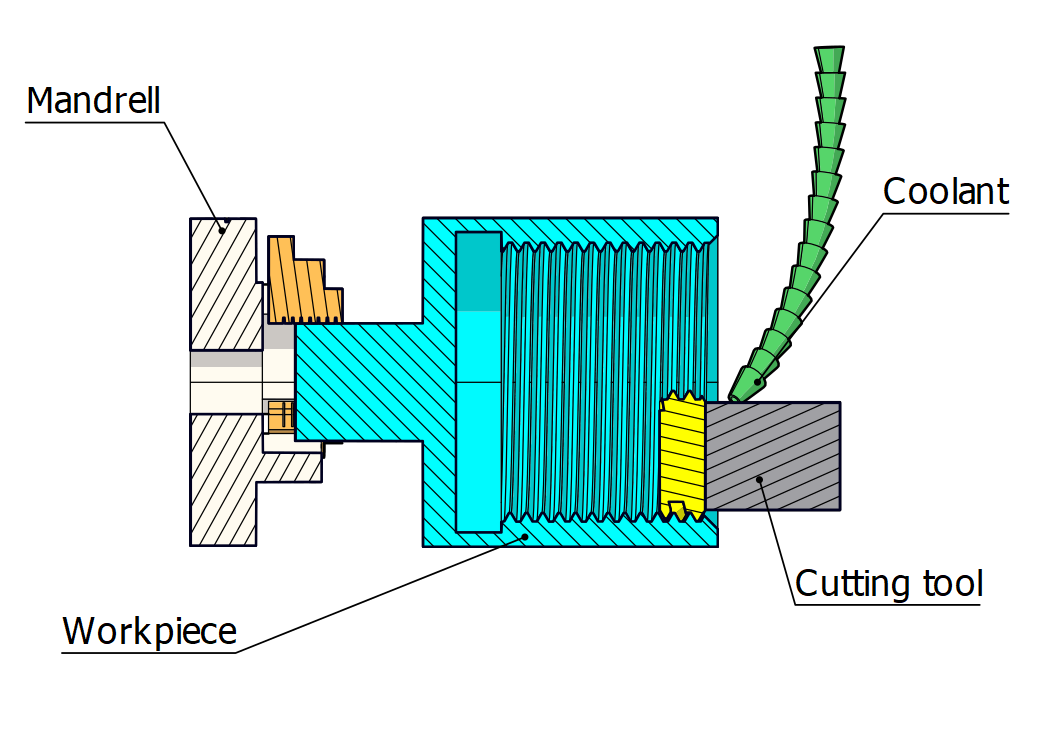

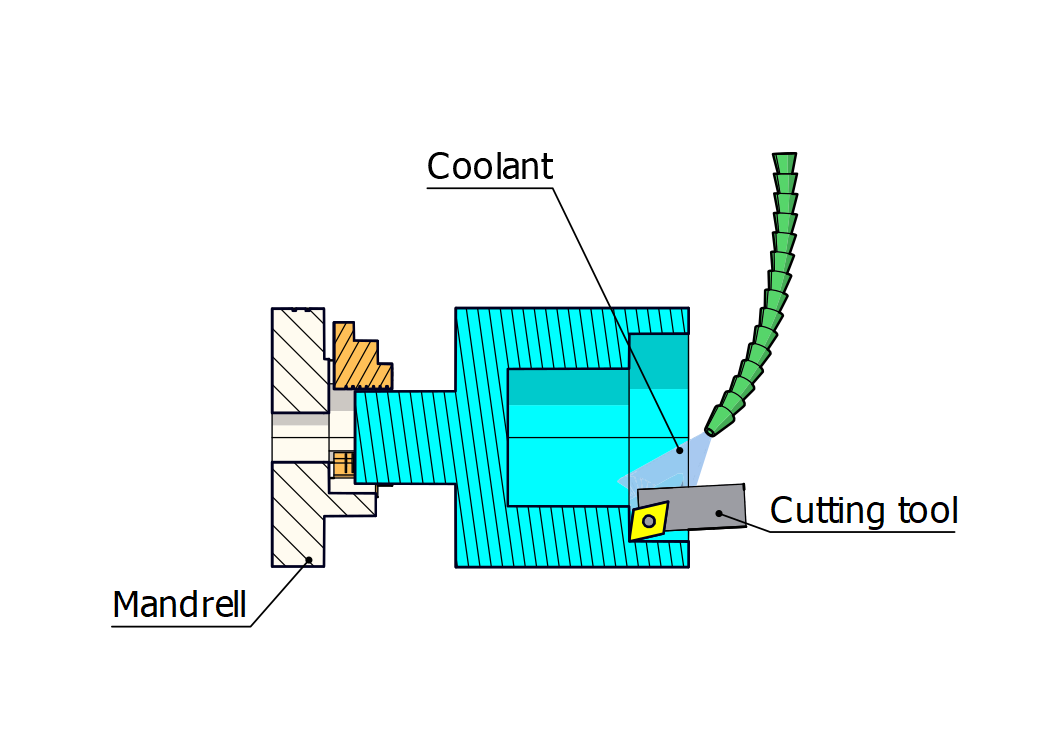

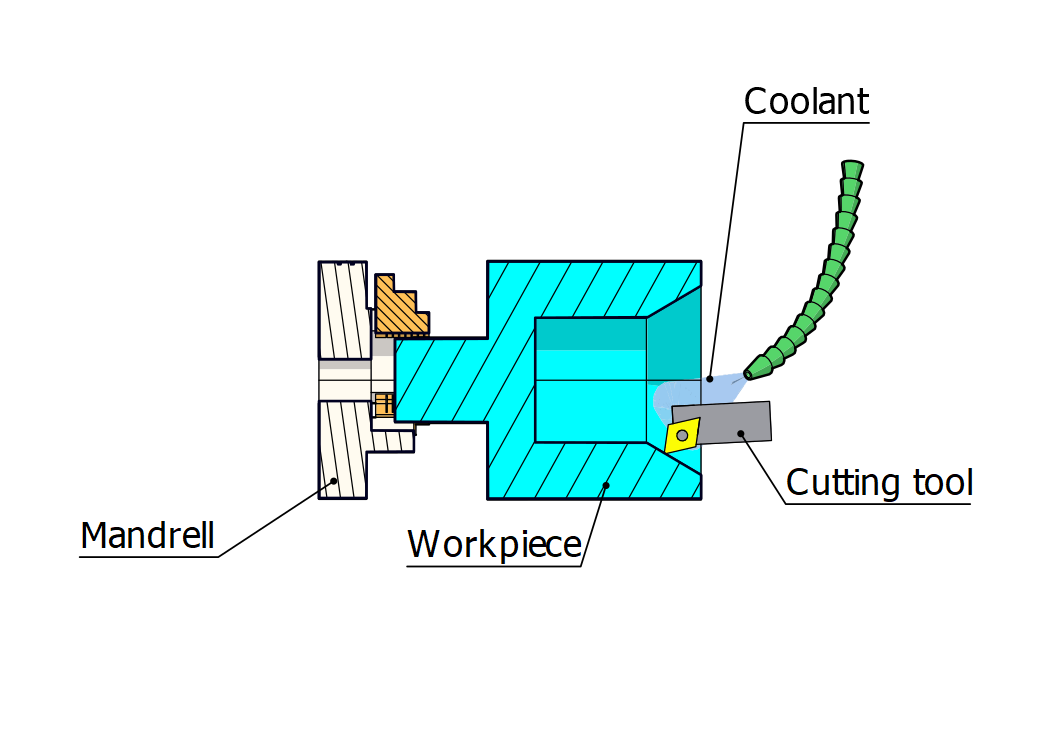

• Applications of subtractive manufacturing: It is widely used in various sectors such as Aerospace, automotive, medical, and oil and gas. It makes gears, jigs and fixtures, and elastomer seals.

• Advantages and disadvantages:

+ Accurate process with lower fabrication costs

- Manufacturabilité is limited to simple shape

3. Formative manufacturing

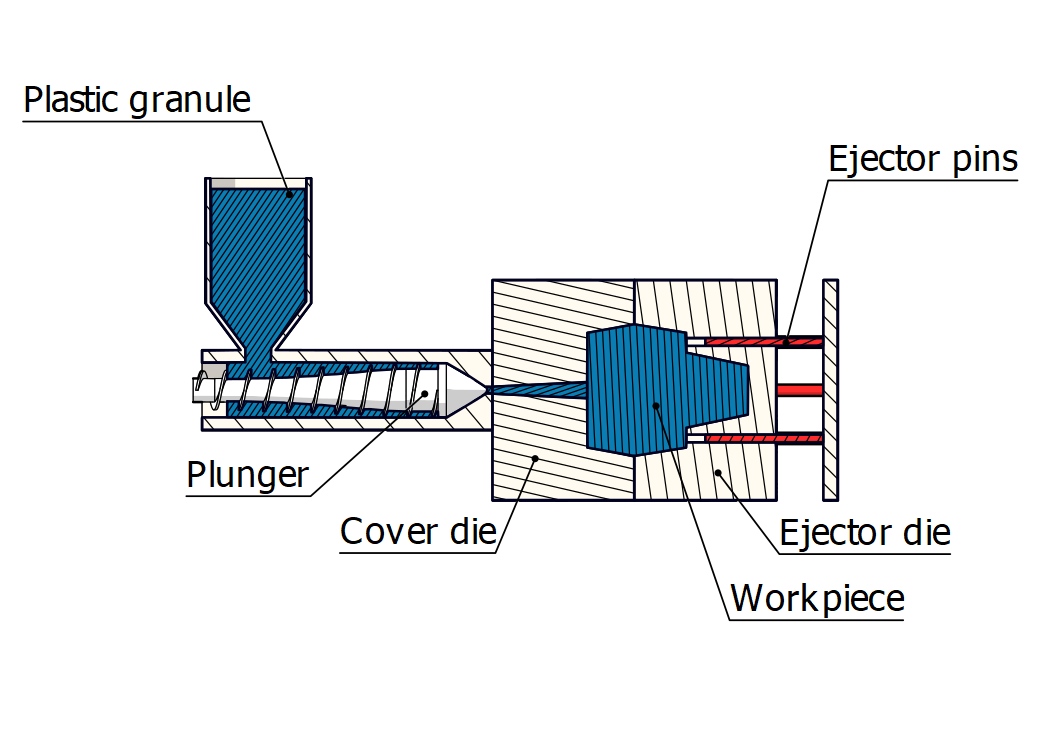

• Injection molding: In injection molding, molten plastic pellets are fed into a mold cavity under high pressure. After the plastic solidifies, the mold is opened, and the part is ejected. Mold is made from hardened steel and contains the shape of the part to be molded. The Injection molding process is used for high and medium-volume production.

English

English