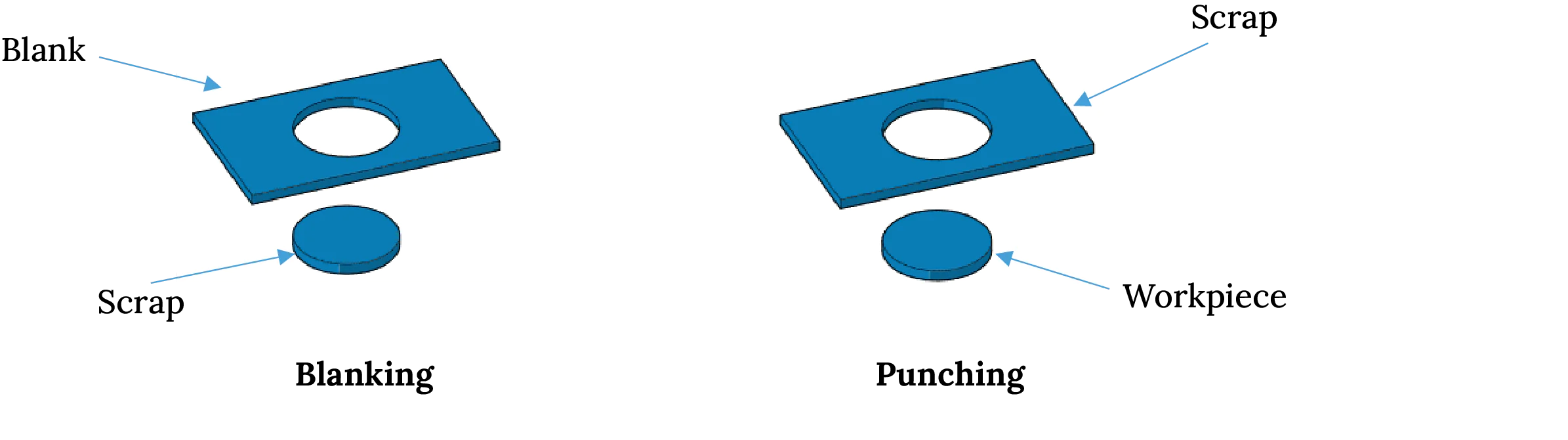

Sheet metal fabrication is the process of cutting, bending, punching, and assembling metal sheets to create parts and products used across various industries. Norck provides high-quality custom sheet metal fabrication solutions tailored to each customer’s specific requirements. Using advanced manufacturing technologies, we ensure precision, durability, and efficiency in every project - whether it involves stainless steel, aluminum, or carbon steel. Our commitment to excellence guarantees products that meet the highest engineering and aesthetic standards.

Through our online manufacturing platform, customers can easily upload their designs, receive instant quotes, and track production progress in real time. Norck’s sheet metal fabrication services cover everything from prototyping to full-scale production. With state-of-the-art CNC machinery and expert engineering support, we deliver on-demand manufacturing solutions that are fast, reliable, and cost-effective, ensuring your projects are completed with precision and on schedule.

English

English